Satoshi Yamasaki (Principal Research Scientist), the Energy Technology Research Institute (ETRI) (Director: Yasuo Hasegawa) and Toshiharu Makino, the Energy Enabling Technology Group (Leader: Shin-ichi Nishizawa), ETRI of the National Institute of Advanced Industrial Science and Technology (AIST) (President: Tamotsu Nomakuchi) successfully enhanced the output power of an ultraviolet (UV) light emitting diode (LED) using semiconducting diamond in cooperation with the National Institute for Materials Science (NIMS) (President: Sukekatsu Ushioda) and Syntek Co., Ltd. (President: Susumu Yamazaki), and also confirmed the sterilization of Escherichia coli (E. coli) in collaboration with the Corporate Advanced Technology Center (Head: Shinobu Kinoshita) of Iwasaki Electric Co., Ltd.

Owing to a global increasing trend of epidemic diseases caused by viruses such as the novel influenza A (H1N1), sterilization has become a critical necessity for society and daily life. Dry sterilization by UV light is a widely employed technique, in which a mercury lamp is used as the light source. However, mercury lamps require bulky equipment, and further, mercury is not environment-friendly. Therefore, there is a need for the development of UV LEDs, which do not contain mercury and facilitate easy sterilization. Although LED illuminations have been widely used as energy-saving light sources, e.g., Christmas illuminations, UV LEDs are yet to be put to practical use. Mercury-free UV LEDs can be employed as portable and easy-to-use germicidal lamps.

AIST has improved the quality of a diamond semiconductor, which is called the ultimate semiconductor, and has been conducting research and development aiming at its application to electronic devices. This has led to the development of LEDs that are based on a novel principle, according to which excitons are used for emitting UV light with a wavelength of 235 nm. We succeeded in developing a diamond LED with an output power of 0.3 mW, which is close to the practical output power value, by improving the quality of the diamond and the structure of the device. We confirmed the sterilization of E. coli by UV light of the diamond LED. The results indicate that the developed diamond LED has potential applications as portable germicidal lamps.

The results will be exhibited at nano tech 2010 International Nanotechnology Exhibition & Conference, commencing on February 17, 2010 at Tokyo Big Sight.

|

|

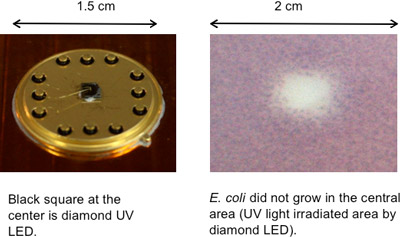

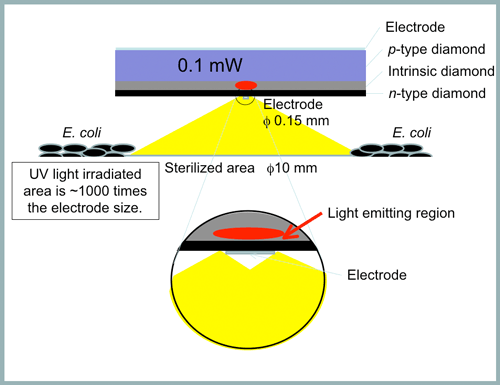

Figure 1 Diamond UV LED and sterilization by UV light |

Owing to a global increasing trend of epidemic diseases caused by viruses such as the novel influenza A (H1N1), sterilization has become a critical necessity for society and daily life. Sterilization is generally carried out by using heat, chemicals, and UV light. In these sterilization treatments, UV light has many advantages as follows: it is effective against thermotolerant bacteria, it has no adverse chemical effects, and it directly acts on the bacterial DNA to inhibit proliferation. Light with a wavelength of around 260 nm—the wavelength at which DNA absorbs light—is capable of significant bacterial sterilization. Although low-pressure mercury lamps that emit 254-nm UV light are currently used, the lamps use mercury, which is environmentally unfriendly. Therefore, the development of semiconductor LEDs is desirable.

Although the development of UV LEDs has been promoted by using LEDs composed of widely used gallium nitride based materials, it is more difficult to fabricate LEDs emitting light of shorter wavelengths. In fact, LEDs that emit light of wavelength 350 nm or shorter are not commercially available.

Although diamond is known to be a good semiconductor, it is not as widely used as silicon because of the difficulties involved in processing methods and improvement in the quality of diamond. AIST has gathered knowledge pertaining to diamond synthesis, electronic device technology, and the physics concerning diamond. On the basis of this knowledge, AIST aimed at the first practical application of diamond to electronic devices and was successful in generating highly efficient UV light emission by excitons, which are characteristic of diamonds (released to the press on August 28, 2006). The LEDs based on the new principle emit 235-nm light, which is effective for sterilization. We successfully increased the luminescent efficiency of the LED by improving the diamond quality and the device structure, and demonstrated its effectiveness in sterilization.

This research and development were promoted in collaboration with NIMS and Kobe Steel, Ltd. (President and CEO: Hiroshi Sato) under the "Research and Development of Nanodevices for Practical Utilization of Nanotechnology" project supported by the New Energy and Industrial Technology Development Organization (NEDO) in FY2007 and FY2008. This research is also being conducted by AIST, Iwasaki Electric Co., Ltd. (President: Takao Kumasaka) and Syntek Co., Ltd. with the support of the product performance evaluation project for small and medium enterprises in the FY2009.

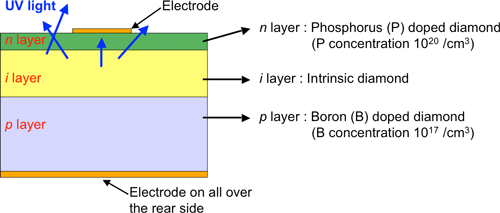

The developed LED has a three-layered structure consisting of an n layer, an i layer, and a p layer, as shown in Fig. 2. This structure was fabricated by the microwave plasma chemical vapor deposition method evolved at AIST. A circular titanium electrode having a diameter of 0.15 mm was deposited on the front side of the LED, and another titanium electrode was deposited all over the rear side.

In the i layer (a light-emitting layer), negatively charged electrons and positively charged holes from the n and p layers, respectively, combine to generate electron-hole pairs, called excitons. The diamond LED utilizes the light emitted from the i layer when the excitons disappear. While conventional LEDs utilize the light emitted during direct recombination of the electrons and holes, the diamond LED is based on a novel principle utilizing the excitons.

|

|

Figure 2 Cross section of the diamond UV LED |

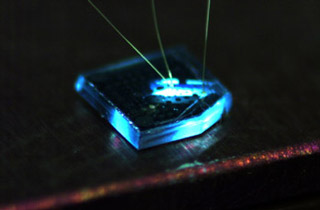

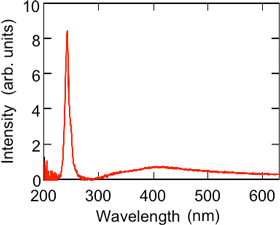

Figure 3 shows light emission from the fabricated LED. Figure 4 shows the emission spectrum; a peak appears at 235 nm, which is characteristic of diamond excitons. Simultaneously, visible light due to the crystalline defects is also observed. Even though most of the generated UV light is obstructed by the electrode as shown in Fig. 5, the emission intensity is 0.3 mW, and the external quantum efficiency is found to be approximately 0.01%.

|

Figure 3 Light emission from the diamond LED

Although UV light is invisible, weak visible light that is simultaneously emitted is observed. |

|

Figure 4 Spectrum of the emitted light

Strong light at 235 nm is emitted. Weak visible light is also observed. |

As shown in Fig. 5, the diamond LED was placed approximately 2 mm above the agar medium on which E. coli bacteria were spread. A current of 300 mA (corresponding to approximately 0.1 mW) was applied, and UV light was irradiated for 100 s (actual irradiation was performed by repeating UV irradiation for 10 ms at intervals of 90 ms. This required 1000 s). The medium was incubated for 24 hours after the irradiation, and the proliferation of E. coli was observed. Figure 6 shows the image of the agar medium that was incubated for 24 hours. From the figure, it could be seen that E. coli did not grow in the UV-irradiated region, indicating the sterilization by the fabricated diamond LED.

Although the electrode was circular with a diameter of only 0.15 mm, the sterilized area was a circle with a diameter of approximately 10 mm. In other words, the sterilized area was nearly 1000 times the electrode area.

In the case of the developed LED, most of the light emitted from the i layer was blocked by the electrode and absorbed internally, and only the light that escaped from the circumference of the electrode was available for sterilization. Nevertheless, the intensity of the emitted light was adequate for confirming sterilization. We intend to improve the device structure to increase the extracting efficiency of the generated light.

|

|

Figure 5 Red areas denote the light emitting regions. Light that escaped from the circumference of the electrode was used for sterilization.

|

|

|

Figure 6 Image of the agar plate on which the E. coli was spread. UV light was directed at the center by the diamond LED, and incubation was carried out for 24 hours. At the point of irradiation, E. coli was killed, while proliferation of E. coli was observed in the surrounding purple area.

|

To enable the applicability of our diamond UV LED to practical sterilization, we will enhance the emission intensity by improving the device structure and substantiate the LED’s rapid sterilization capability.