Update(MM/DD/YYYY):12/19/2019

The World’s First Practical-sized Protonic Ceramic Fuel Cell (PCFC)

– Produced using a diffusion sintering technique suitable for mass production –

Researchers: FUJISHIRO Yoshinobu, Leader, YAMAGUCHI Toshiaki, Senior Researcher, SHIMADA Hiroyuki, Senior Researcher, and YAMAGUCHI Yuki, Researcher, Functional Integration Technology Group, Inorganic Functional Materials Research Institute, and MIZUTANI Yasunobu, Visiting Researcher (Toho Gas Co., Ltd.)

Summary

The researchers have developed a new diffusion sintering technique for difficult-to-sinter proton-conducting ceramics (protonic ceramics). They produced an 8-cm square cell that exhibits better power generation performance than conventional solid oxide fuel cells (SOFCs) and is of sufficient size for practical application.

|

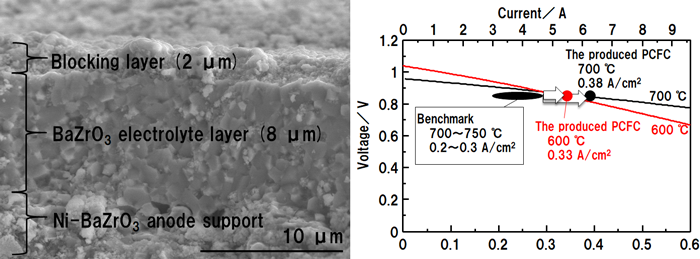

Cross-sectional image of the electrolyte layer (left)

and voltage-current characteristics of a 5-cm square single flat cell (right) |

Background

The theoretical power generation efficiency of an SOFC that uses a protonic ceramic as the electrolyte layer is much greater than one that uses a conventional oxide-ion conducing ceramic. However, it is difficult to produce large protonic ceramics, because the sintering temperatures above 1700˚C are typically required. To lower this temperature, a sintering aid is normally added, but this segregates at grain boundaries, resulting in poor electronic insulating behavior. Therefore, there is a strong need for a manufacturing process that can produce practical-sized protonic ceramics that retain their high proton conductivity and low electronic conductivity.

New findings

Using the new technique developed in a NEDO R&D project, the sintering aid-containing anode support layer and the thin electrolyte layer are pressed together and sintered in the same furnace, so that the sintering aid diffuses into and throughout the ceramic electrolyte. Since the sintering aid does not segregate at the boundaries between the crystallites that make up the ceramic (grain boundaries), its electronically insulating behavior is preserved. The developed technique allows the ceramic to be densely sintered at a temperature 200˚C lower than the conventional sintering temperature. This process can be easily scaled up for mass production, and the researchers have already produced a PCFC cell larger than 5 × 5 cm2 in area, a size sufficient for practical application. The PCFC exhibited excellent power generation performance at an operating temperature 100˚C lower than that of conventional SOFCs.

Future plans and potential for application

The researchers at AIST plan to produce a test PCFC stack by combining single cells in multiple layers. They will evaluate its efficiency, identify any technical challenges, and conduct industry-academia-government collaborative research to further develop this high-efficiency fuel cell.