Researchers: EBINA Takeo, Prime Senior Researcher, Research Institute for Chemical Process Technology, and ISHII Ryo, Leader, Functional Materials Processing Group of the institute

Together with the Forestry and Forest Products Research Institute, Miyagi Kasei Co., Ltd. and Mitsuoka Motors Co., Ltd., the researchers have commenced the world’s first evaluative tests of interior and exterior automotive parts manufactured from glass fiber-reinforced plastic using glycol lignin sourced from Japanese cedar as a resin component using an actual vehicle.

|

|

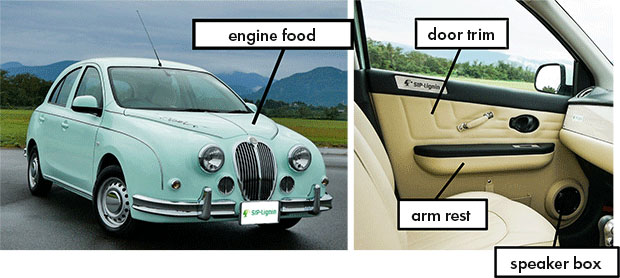

Prototype car using glycol lignin for interior and exterior parts |

Lignin is one of the main components of wood (representing approximately 30%), and has a chemical structure containing aromatic rings. Materials with aromatic rings have the potential to display excellent qualities including heat resistance and flame retardancy, but despite this, as yet there has been no full-scale commercialization of materials that employ lignin.

In the project, “Technologies for creating next-generation agriculture forestry and fisheries” of the Cross-Ministerial Strategic Technology and Innovation (CSTI), the researchers aimed to develop and establish a manufacturing process for a glass fiber-reinforced plastic (GFRP) using glycol lignin as a resin component. A liquid curing agent was added instead of a solvent in order to reduce viscosity, and the material was placed in a mold in an oven in which the temperature had been adjusted to a higher temperature than normal, but which prevented curing of the resin. The resin was uniformly impregnated using the vacuum impregnation method. A variety of composite materials were developed, manufacturing processes were examined, and performance and long-term durability were evaluated in cooperation with companies involved in the project. The results verified that the GFRP using glycol lignin possesses a tensile modulus 10-20% higher than conventional GFRP, and in addition that the tensile modulus was higher than that of conventional GFRP and durability was greater even after long-term durability tests.

In the future, the researchers will monitor changes in the automotive interior and exterior parts due to factors including ultraviolet light and temperature changes over the course of approximately one year, in order to confirm that the developed material is fit for practical use over the long term. They intend to brand environmentally friendly vehicles using glycol lignin in 2022.