Update(MM/DD/YYYY):02/06/2017

Film-Type Capacitive Proximity Sensor That Monitors a Person’s Movements and Breathing

– Development of a non-contact motion sensor that adheres to the back of a floor or of a bed, and a printing-based manufacturing method for the sensor –

Points

-

Installed by merely adhering to somewhere out of sight, detecting a person’s movements and breathing

-

Easily manufactured by screen-offset printing technology

-

Expected to lead to a practical personal monitoring system without physical or mental strain on the user

Summary

Ken-ichi Nomura (Researcher) and Hirobumi Ushijima (Leader, also Deputy Director of the research center), the Advanced Surface Processing Team, the Flexible Electronics Research Center (FLEC; Director: Toshihide Kamata), and Ryosaku Kaji (Senior Researcher) and Kazuhiro Kojima (Leader), the Smart Communication Research Group, the Intelligent Systems Research Institute (Director: Kazuhito Yokoi), the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi), have developed a technology to manufacture non-contact film-type capacitive proximity sensors that can be positioned out of sight and used to detect persons’ movements and breathing without physical or mental strain to the user, in collaboration with Shiro Iwata (Senior Researcher) and Naoto Imawaka (Project Manager), Project for Organic Flexible Electronics, and Shinobu Otao (Project Manager), Project for Next Generation Power Electronics, Shimane Institute for Industrial Technology (Director: Katsumi Yoshino).

The developed film-type proximity sensor is a capacitive-type sensor having electrodes of different sizes on the front and reverse sides of the film. It was produced with a double-sided printing-based manufacturing technology that easily creates electrode structures on both sides of the sensor using the screen-offset printing technology developed by FLEC.

Details of the technology was published in the online version of a British scientific journal, Scientific Reports, on January 22, 2016 (UK time), and a relevant technology will be exhibited at Printable Electronics 2016 to be held on January 27-29, 2016 at Tokyo Big Sight (Koto, Tokyo).

|

|

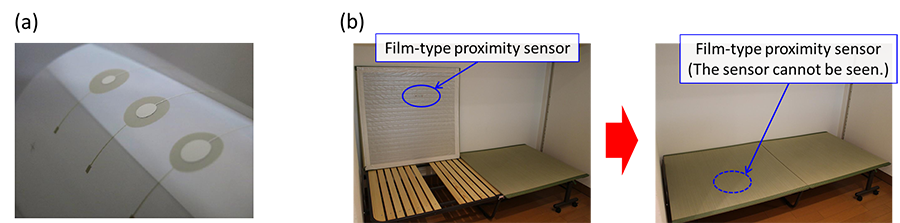

(a) Film-type proximity sensors (b) Sensor applied to the underside of a tatami bed |

Social Background of Research

Nursing care has become a major issue for Japan with its rapidly aging society. On the other hand, it is also the focus of attention as an opportunity to found new industries. A typical example is the so-called “personal monitoring industry,” which would use big data to support nursing care. For example, day-to-day health and lifestyle information could be stored as digital data, which would then be analyzed and put to use helping to prevent falls and other accidents and to sense mental and physical problems before symptoms appear. This could help lower medical costs. The analyzed data could also reveal unknown nursing care needs.

There are a number of approaches to the development of the sensing technology to acquire the data. One uses contact sensors such as wearable sensors, which are potentially very convenient tools. Ultimately, however, it is desirable to acquire data without physical contact with the user, so that there is no physical or mental strain on the user. Non-contact sensing technologies currently available use infrared light, radio waves, or cameras. Because of privacy concerns, however, installation places of tools like cameras are limited, so such tools tend to have blind spots. Since sensors cannot detect their subject if another object is in the way, they have to be placed where people can see them. The problem here is that the visibility of the sensor impacts the person’s lifestyle and mental state. Infrared and radio wave sensors require expertise to determine where to place them and how to adjust the direction of the beam to enhance detection precision. The technical problem with these sensors is that installation itself is difficult for the ordinary person or business.

History of Research

AIST has been researching and developing flexible devices as a new type of device that are thin, lightweight, and easy to make into various shapes. It has also been developing new printing technologies, including a screen-offset printing technology, to produce these devices in large quantities or large sizes at low cost.

Some of the desirable properties of non-contact monitoring sensors are that they can be thin enough, lightweight enough, and if possible flexible enough to place anywhere, that they can be installed in large quantities or sizes, and that they can be manufactured inexpensively. Other desirable properties that the present development is aiming at include less mental strain on the user and the ability to use the sensor anywhere by simply laying it out or attaching it to a surface. AIST has developed a film-type capacitive proximity sensor that can be used easily by simply attaching it to a wall, floor, or bed, can be placed out of sight by positioning it on the back of these surfaces, and can be used to detect a person’s movements and breathing in a way that lets the user act naturally.

The Shimane Institute for Industrial Technology has expertise in various types of simulation technologies required to manufacture electronic devices. For the present development, the institute ran electric field simulation to design and optimize the structure of the proximity sensor. The result was the early development of non-contact sensing technology that “does not make people aware the sensor is even there.”

Details of Research

The developed film-type proximity sensor has a capacitor structure with electrodes on the front and reverse sides of the film. When used, AC voltage is applied between the electrodes. If the sizes of the electrodes on the front and back are the same, the generated lines of electric force tend to be confined between the electrodes, but if the sizes are different, the lines of electric force leak into the surrounding area. When a person gets close to a sensor under this condition, some of the lines of electric force orient themselves in the direction of the person, which causes the capacitance between the electrodes to change. This is how the person’s proximity is detected. When AC voltage of a frequency that does not allow the lines of electric force to be blocked by ordinary flooring, mattresses, etc. is applied (200 kHz was used in the developed sensor), the sensor can detect the proximity of a person on the front side of that object, even if the sensor is hidden behind it. Moreover, although the operating principle is the same as that of the capacitive touch panel sensors used in smartphones, tablets, and the like, the developed film-type sensor need not be touched; objects need only come close to the sensor to be detected.

One possible procedure for manufacturing a structure with electrodes on both sides by printing would be printing the front side with conductive ink (the material that forms the electrodes) first, then heating it to bake the ink. After that, the sheet would be flipped over so the reverse side can be printed, after which the ink on the back is baked. This approach, however, requires performing the time-consuming baking process twice. (The time will vary by type of ink, but in most cases at least several minutes would be required.) It would be preferable if the two electrodes could be baked with a single heating process to shorten the production time.

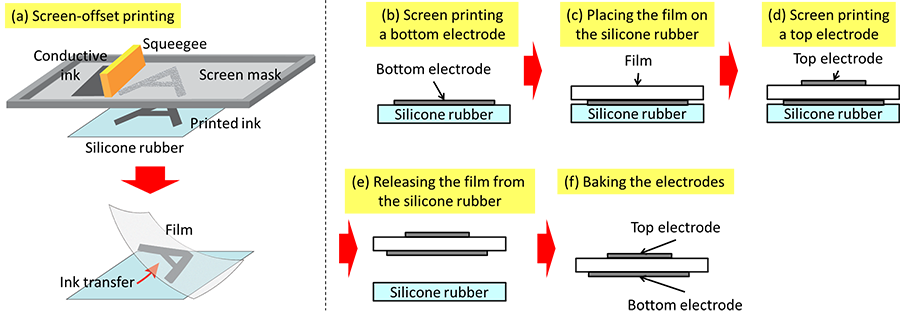

To that end, a screen-offset printing technology (Fig. 1 (a)) developed by AIST was used in the developed technology. In screen-offset printing, the desired ink pattern is screen-printed on a silicone rubber blanket, and then the pattern is transferred from the silicone blanket to the substrate. To manufacture the developed sensors, a conductive ink pattern, which becomes the lower electrode, is screen-printed onto a silicone rubber blanket first (Fig. 1 (b)) and then a film which becomes the substrate of the sensor is placed on the rubber blanket (Fig. 1 (c)). Next, the upper electrode pattern is screen-printed on the front side of the film (Fig. 1 (d)), and the film is released from the silicone rubber blanket. At this time, the electrode pattern on the reverse side is transferred from the silicone rubber blanket to the film (Fig. 1 (e)). Finally, the ink patterns on both sides are heated once to bake them and finish the sensor (Fig. 1 (f)). With this technique, it is easy to form electrode patterns on both sides of the film.

|

|

Figure 1 (a) Overview of screen-offset printing; (b) - (f) Manufacturing method for electrodes of a film-type capacitance proximity sensor |

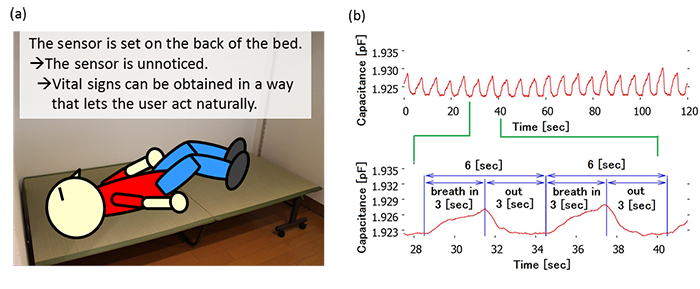

The sole purpose of an ordinary proximity sensor is to detect the approach of people. However, the researchers thought that if a sensor could selectively detect the motion of the chest of a stationary person, it could be possible to detect breathing, so this was tested. A film-type proximity sensor was placed on the underside of a tatami bed. A subject laid on the bed as in Fig. 2 (a) and breathed in cycles of three seconds inhaling and three seconds exhaling. Figure 2 (b) shows changes in the sensor signal (capacitance) during this experiment. The signal changes synchronized with the breathing cycles, showing that the sensor was able to accurately detect the breathing of a reclining person.

|

Figure 2 (a) Image of using the developed sensor as a bed sensor

(b) Capacitance of the sensor when the subject on the bed breathed rhythmically |

Future Plans

The next step will be to establish a technology to detect early signs of accidents and illnesses based on measurement data taken from these sensors. As a launching point, the researchers have begun considering proving tests of related technologies in collaboration with Takeshi Isobe (Professor) of the Shimane University Hospital. Currently, data is collected from sensors by physically connecting to a large measuring device (about 33 × 12 × 18 cm3), but for safety and practicality during testing, they are examining how to make the system smaller and wireless. The researchers also aim to make the sensors more sensitive so they can detect heart rate and pulse, for example by optimizing sensor structure. They also hope to develop a technology to convert the currently single-element sensors into a two-dimensional array and develop advanced devices that can detect human motion in three dimensions. These technologies will be further perfected in the future to help build systems that can operate in the home and respond to the growing need for home nursing care and monitoring.