Based on the achievements of a NEDO project, Zeon Corporation (ZEON) has completed and begun operation of the world’s first mass production plant for carbon nanotubes (CNTs) using the Super-growth (SG) method developed by the National Institute of Advanced Industrial Science and Technology.

The SG method enables high speed, large quantity synthesis, and CNTs made with the SG method have high aspect ratio, high purity, and large surface area compared with conventional CNTs. They bear high expectations for application in new functional materials and next generation devices with as of yet unseen functions and characteristics. Increasing demand is expected, as they can be applied to innovative materials and devices, including high-performance capacitors, highly functional rubber materials, and high-heat conductive materials.

Zeon Corporation began mass production in November, 2015.

|

SGCNT mass production plant

(Zeon Corporation Tokuyama Plant) |

Carbon nanotubes were discovered by Dr. Sumio Iijima of Japan, and Japan currently leads the world in researching this material. Its light weight, high strength, and high electrical and thermal conductivity lend to great expectations for its use in a variety of applications.

In the NEDO project “Nanocarbon Application Product Creation Project” (FY2003 to FY2005), the National Institute of Advanced Industrial Science and Technology (AIST) developed the base technology of the Super-growth method (SG method), an innovative CNT synthesis method found by Dr. Kenji Hata of AIST in 2004. In the “Carbon Nanotube Capacitor Development Project” (FY2006 to FY2010), AIST and ZEON advanced development of carbon nanotube (CNT) mass production technology. Additionally, AIST and ZEON started construction of a mass-production demonstration plant through the FY2009 Ministry of Economy, Trade, and Industry supplementary budget project, and since 2011 have promoted technology dissemination activities by providing samples.

Recently, ZEON has used technology derived from the AIST mass production demonstration plant to complete the world’s first mass production plant for high quality CNTs produced with the SG method (SGCNTs).

Because SGCNTs display such traits as high aspect ratio, high purity, and large surface area compared with other CNTs, this material bears expectations for application to new functional materials and next generation devices with as of yet unseen functions and characteristics. This suggests the possibility of innovative materials and devices, including high-performance capacitors, highly functional rubber materials, and high-heat conductive materials, and demand is also expected to expand greatly. In order to meet the demand in the market for these applied products, ZEON began mass production of SGCNTs from November, 2015.

[1] Development of SGCNT mass production base technology

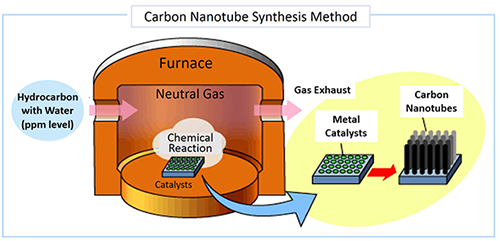

In the NEDO project, AIST and ZEON have built inexpensive catalyst deposition technology, large-area synthesis technology, and continuous synthesis technology, which are especially important within the SG method. Figure 1 shows the SG method. The SG method is an excellent CNT synthesis method that greatly improves the activity and life span of a catalyst, and maintains high growth efficiency by adding a small amount of moisture to the gas-phase synthesis furnace atmosphere. Compared with conventional CNT synthesis, synthesized SGCNTs show hundreds of times the growth efficiency and can be easily separated from the substrate, therefore SGCNTs with a carbon purity of over 99 % can easily be collected, allowing for a significant reduction in catalytic usage and manufacturing cost.

|

|

Figure 1: The SGCNT synthesis method |

[2] Technology dissemination activities by the SGCNT mass production demonstration plant and construction/completion of the mass production plant

In a Tsukuba Innovation Arena Nanotechnology (TIA-nano) project, AIST and ZEON used the mass production base technology built with the NEDO projects to construct the SGCNT mass production demonstration plant within AIST (FY2009 Ministry of Economy, Trade, and Industry supplementary budget project), and succeeded in uniformly synthesizing SGCNTs on 500 × 500 mm metal substrates. As a result, they achieved approximately 17,000 times the production capacity compared with when the SG method was first discovered. AIST began offering synthesized SGCNT samples as research samples, now provided to over 200 domestic companies and universities. Since FY2013, ZEON has leased this plant from AIST and begun providing SGCNT samples, supporting studies by domestic research institutions and companies aimed at commercialization of SGCNT applied products.

Furthermore, in the NEDO “Nanocarbon Material Practical Application Project to Achieve a Low-carbon Society” (FY2010 to FY2016), the Technology Research Association for Single Wall Carbon Nanotubes (TASC) advanced development of composite SGCNT materials. As applied products that take advantage of the excellent features of SGCNTs, TASC developed highly conductive rubber exhibiting high mechanical durability, conductive rubber and plastic made by adding a very small amount of SGCNTs, SGCNT/carbon fiber/rubber composite materials having thermal conductivity on par with titanium or iron, and other such polymer composite materials that exhibit excellent features that cannot be obtained by conventional fillers, such as carbon black. In addition, research and development relating to metal composite materials have also shown significant progress, as light-weight copper composite materials with higher allowable current density, as well as aluminum composite materials having three to four times the thermal conductivity of aluminum have been developed, which are expected to be applied to next-generation transport equipment and electronic devices.

In April 2014, in order to meet the demand in the market for the applied products, ZEON decided to construct an SGCNT mass production plant within its Tokuyama Plant by utilizing the technology obtained from AIST’s mass production demonstration plant and completed construction on November 11, 2015 for the launch of mass production.

It is assumed that the completion of this SGCNT mass production plant will spread innovative composite materials and applications of SGCNTs as a core material. Since the scope of applications is expected to be broad, spanning across the energy, electronics, functional materials, and structural materials fields, creating a large industry in Japan, ZEON will carry out mass production of SGCNTs as planned, thereby contributing to the development of the Japanese economy.