Yoshihiro Aiura (Leader), Ruiping Wang (Senior Researcher), and others of Oxide Electronics Group, the Electronics and Photonics Research Institute (Director: Satoshi Haraichi) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi), have developed a high-performance piezoelectric ceramic without the lead that is harmful to human health and the environment (lead-free piezoelectric ceramic).

Evaluation of the piezoelectric properties of this lead-free piezoelectric ceramic according to the standard of the Japan Electronics and Information Technology Industries Association (JEITA) revealed high performance rivaling that of conventional lead-based piezoelectric materials. Additionally, acoustic emission (AE) sensors and ultrasonic distance sensors (for underwater and atmospheric use) designed and prototyped based on the results of piezoelectric property evaluation demonstrated approximately the same level of performance as sensors that use lead-based piezoelectric materials, indicating the possibility of practical lead-free piezoelectric sensors. The developed lead-free piezoelectric ceramic is expected to be used in safe piezoelectric sensors.

Details of the technology will be presented at the 13th International Nanotechnology Exhibition & Conference (nano tech 2014) held on January 29-31, 2014, at Tokyo Big Sight (Koto, Tokyo).

|

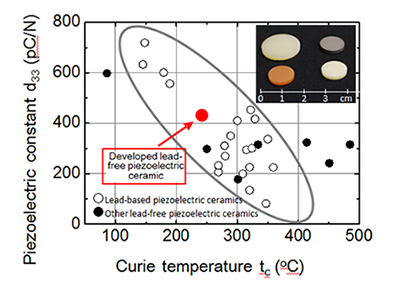

(Figure) : Comparison of properties of developed lead-free piezoelectric ceramic and existing lead-based piezoelectric ceramics

Area within an ellipse shows scope of piezoelectric properties of conventional lead-based piezoelectric ceramics.

Photo at upper right shows developed piezoelectric material. Red and black pellets contain a trace amount of element

that was intentionally added to them to adjust their properties. |

Piezoelectric materials are unique in that they can convert mechanical energy to electrical energy and vice versa. They can be used as sensors and actuators. Their applications range widely, from leading-edge electronic devices (fine-movement stages of semiconductor exposure apparatus, precise adjustment mechanism for scanning-type probe microscopes, etc.) to general-purpose electronic devices (inkjet printer heads, shake correction elements of digital cameras, etc.). As such, piezoelectric materials have become essential to our lives in society. However, the piezoelectric material incorporated into electronic devices is Pb(Zr,Ti)O3 (PZT), a piezoelectric ceramic consisting mainly of lead and therefore having a significant burden on human health and the environment.

With the growing awareness of environmental problems in recent years, interest in materials free of harmful metals like lead and cadmium has risen rapidly, not only in Europe but also in Asia. Europe has established the RoHS Directive and ELV Directive, basically banning the use of lead, mercury, cadmium, and the like, to reduce the environmental burden of waste electrical and electronic equipment. Because it contains lead, PZT is subject to the RoHS Directive, but it is also granted an exemption under the directive since there are no piezoelectric materials with the same properties that can substitute for it. Thus, the development of high-performance lead-free piezoelectric ceramics that can substitute for lead-based piezoelectric ceramics has become a global issue.

It is known that lead-based piezoelectric ceramics with compositions near the tetragonal/rhombohedral morphotropic phase boundary have enhanced piezoelectric properties. In 2001, AIST began developing high-performance lead-free piezoelectric materials with compositions near the tetragonal/rhombohedral morphotropic phase boundary, with research focusing on sodium potassium niobate, a perovskite oxide without lead.

Part of the present research and development was conducted through the project “Verification of Practicality of Niobium-Based Lead-Free Piezoelectric Ceramic Material Electronic Devices” (FY2013) of the Japan Science and Technology Agency’s Adaptable & Seamless Technology Transfer Program through Target-driven R&D (A-STEP). Lead-free AE sensors were developed in “Technology to Automate and Lower the Cost of Inspection by the Use of IT for Irregular Sound Detection, Etc.,” a project within AIST.

The crystalline structure of the newly developed lead-free piezoelectric ceramic can be continuously controlled from the tetragonal to the rhombohedral phase. By optimizing the piezoelectric properties with a composition near the tetragonal/rhombohedral morphotropic phase boundary, the researchers derived a high Curie temperature tc (240 °C) and high piezoelectric constant d33 (420 pC/N) at the same time. These piezoelectric properties rival the conventional lead-based piezoelectric ceramic PZT incorporated in existing electronic devices.

However, besides Curie temperature tc and the piezoelectric constant d33, there are more than 20 other property parameters of piezoelectric ceramics that are necessary to design electronic devices. Unless all these parameters are evaluated by the standard methods, electronic devices using piezoelectric ceramics cannot be designed. In order to enable the developed lead-free piezoelectric ceramic to be incorporated into electronic devices, the piezoelectric properties of the ceramic were evaluated according to JEITA Standard EM-4501, “Electrical Test Methods for Piezoelectric Ceramic Vibrators.” Evaluation results for the developed lead-free piezoelectric ceramic and for PZT5A, a typical lead-based soft piezoelectric ceramic, are given in Table 1. As the table shows, the piezoelectric properties of the developed lead-free piezoelectric ceramic rival those of the lead-based material, and therefore it is expected that the developed material can be used in electronic devices.

*Figures in parentheses were measured with a d33 meter

For dielectric loss, the lower the figure, the better the piezoelectric material. For other piezoelectric properties, the higher the figure, the better the material.

AE sensors and ultrasonic distance sensors (for underwater and atmospheric use) were designed and prototyped based on the results of piezoelectric property evaluation, and the possibility of practical lead-free piezoelectric sensors was verified.

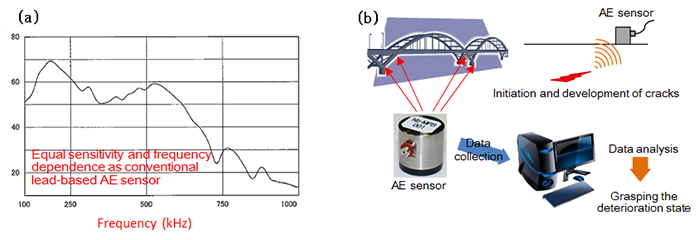

●AE sensors

In recent years, structural health monitoring with AE sensors has gained considerable attention as a way of extending the life of social infrastructure and lowering the cost of its maintenance and management. The piezoelectric material incorporated into conventional AE sensors is most often PZT, but because social infrastructure is located outdoors, there has been a need for lead-free AE sensors to lower environmental burden. AE sensors using the developed lead-free piezoelectric ceramic show the same level of sensitivity as conventional lead-based AE sensors, verifying that the former can substitute for the latter (Fig. 1).

|

|

Figure 1 : (a) Sensitivity property of lead-free AE sensor; (b) Image of structural health monitoring with AE sensors |

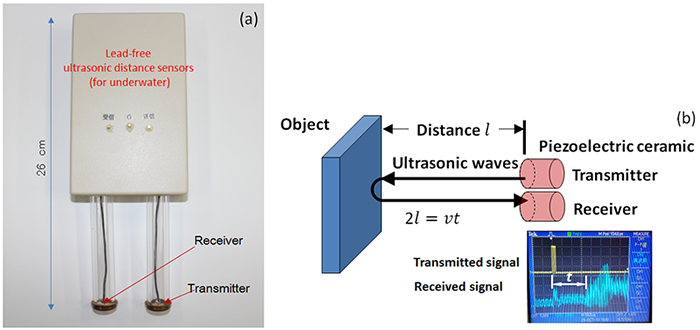

●Ultrasonic distance sensors

If distance sensors using lead-free piezoelectric ceramics were combined with other electronic devices to develop multifunction combined devices, those devices would no longer be subject to limitations imposed on electronic device waste. Figure 2 shows a photo of an underwater distance sensor using the developed lead-free piezoelectric ceramic. The sensor demonstrated measuring precision within 5 mm, verifying that it has about the same level of precision as conventional sensors using lead-based piezoelectric ceramics.

|

|

Figure 2 : (a) External view of lead-free underwater distance sensor; (b) Measuring principle of ultrasonic distance sensors, with their transmitted and received signals (inset). |

The researchers will work to make incorporation of the developed lead-free piezoelectric ceramic into electronic devices practical, further improve the ceramic material, and prototype an actuator. In addition, they will explore potential research collaborators in the pursuit of practical electronic devices incorporating the lead-free piezoelectric ceramic.