Update(MM/DD/YYYY):10/11/2013

Mass-production of High-performance Surfactants from Non-edible Biomass Using Yeast

- Reducing the cost of biomass-derived chemicals, avoiding competition with foods -

Points

-

Technology to mass-produce naturally-derived surfactants (biosurfactants) using yeast and non-edible biomass (non-edible oil) has been established.

-

Compared to synthetic surfactants, only a small quantity of the developed biosurfactants exerts a variety of functions.

-

Exhibiting high biodegradability and having excellent detergency, it is expected that the biosurfactants will be applied to a wide range of products including detergents and daily necessities.

Summary

Dai Kitamoto (Deputy Director) and Tomohiro Imura (Senior Researcher), the Research Institute for Innovation in Sustainable Chemistry (Director: Hiroshi Yanagishita) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi), in collaboration with Allied Carbon Solutions Co., Ltd. (ACS; CEO: Yosuke Yamagata), and Koji Wada (Professor) and others of Faculty of Agriculture (Dean: Yasuhiro Kawamoto), the University of the Ryukyus (Univ. Ryukyu; President: Hajime Oshiro), have established the technology to mass-produce naturally-derived high-performance surfactants called "biosurfactants" from non-edible biomass.

With the increasing awareness of the need to establish a low-carbon society, it is becoming more and more important for the chemical industry to utilize renewable resources, not depending solely on petroleum. In particular, there is an urgent need to produce a variety of chemicals from non-edible biomass that does not compete with foods. Bio-fuels are already produced utilizing non-edible biomass. However, the utilization of non-edible biomass for chemical products has been extremely limited due to constraints regarding synthesis technology and those of cost.

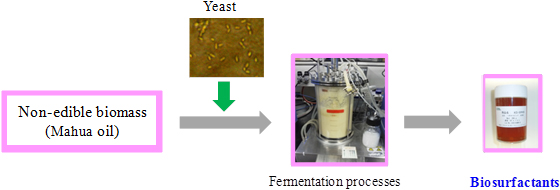

In the present research, the researchers have succeeded in producing biosurfactants directly from a non-edible biomass material, mahua oil, by a fermentation process using yeast, and also in establishing the technology for their inexpensive mass supply by optimizing the fermentation conditions and the method of separating products (Fig. 1). These biosurfactants, which not only have excellent detergency at low concentrations but also exhibit high biodegradability, are expected to be used in toiletry products such as detergents and shampoos that are friendly to the environment.

|

|

Figure 1 : Production of biosurfactants from non-edible biomass using yeast |

Social Background of Research

With the emergence of problems such as global warming, it is becoming increasingly important to develop technologies to promote the conversion of raw materials from petroleum to renewable resources such as biomass, aiming to break away from fossil resources. In particular, non-edible biomass materials, including cellulose and mahua oil, are drawing attention; these can be inexpensively supplied and their price fluctuation is relatively small, as they do not compete with foods. Bio-fuels are already produced utilizing non-edible biomass, its utilization for chemical products has been very limited due to constraints regarding synthesis technology and those of cost. However, in order to accelerate the utilization of biomass, its application into chemical products that have additional value greater than fuel is desired.

On the other hand, more than a million tons of surfactants are produced every year within Japan alone and are used in daily necessities such as kitchen detergents and shampoos. They are also used in a wide range of industries, including machine, building, and engineering industries. Since there is the possibility of these surfactants being diffused into the environment after use, there is a demand for high-performance products that are safe, have a low environmental impact, and exert their functions in smaller quantities. Currently, most surfactants are petroleum-derived, and compared to them, biosurfactants that are produced from various biomass by microorganisms, including yeast and bacteria are not only friendly to the environment and living organisms but also demonstrate their effectiveness at low concentrations. From the viewpoints of the conversion of raw materials and high functionality as well as environmental impact, the development of biomass-derived products is required.

History of Research

As part of its development of environmentally friendly biomaterials, AIST has conducted the research in biosurfactants and discovered that they can be produced efficiently from vegetable oils such as soybean oil through a fermentation process using yeast found by AIST (AIST Press Release on September 7, 2006). At the same time, in collaboration with Univ. Ryukyu, AIST has initiated research on the diversification of raw materials for biosurfactants and analyses of their functions, in order to advance applied research utilizing their properties. In the meantime, ACS has been developing its business of producing fuel from non-edible oil as a substitute for fossil fuels. Utilizing its accumulated know-how, ACS has been in search of a new business based on chemicals with higher added value. ACS's attention to AIST’s research and development of biosurfactants has led to the joint research.

Details of Research

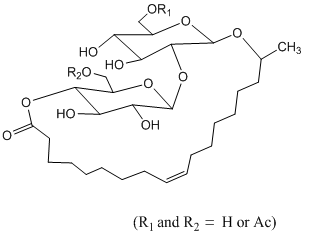

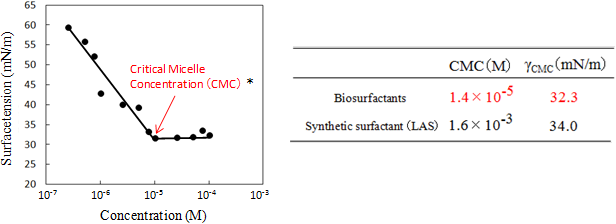

AIST searched for a microorganism that can produce biosurfactants from mahua oil, which is non-edible oil native to India and provided by ACS and among ten or more kinds of microbial strains, a kind of yeast that can efficiently produce biosurfactants was discovered. In addition, the researchers have identified the structures of the biosurfactants produced from the mahua oil. The chemical structures of the obtained biosurfactants are shown in Fig. 2. Moreover, when the functions of these biosurfactants were investigated, they were found to have excellent surface activity (i.e. detergency) at low concentrations. Consequently, their application to high-performance surfactants can be expected (Fig. 3).

|

|

Figure 2 : Structures of the biosurfactants |

|

|

Figure 3 : Surface activities of the biosurfactants

● indicates the surface tension value of the aqueous solution of the biosurfactants at each concentration level. *The critical micelle concentration (CMC) is the standard for assessing the performance of the surface active agent. A lower CMC value suggests that a smaller quantity of the surface-active agent is needed to exhibit its detergency. γCMC is the surface tension value at CMC. |

Furthermore, in a collaborative effort with Univ. Ryukyu, AIST optimized the composition of culture solution (oil, nitrogen, vitamins, inorganic salts, etc.) and the fermentation conditions. Based on these basic technologies, ACS has investigated industrial mass-production of the biosurfactants from mahua oil, a non-edible biomass resource, and established a technology for the mass-production of them. ACS has positioned the biosurfactants as a pillar of its new business and started providing samples to manufacturers in various industries.

Future Plans

AIST continues to search for and develop biosurfactants with new structures and new properties with the aim of promoting the production of biomass-derived chemical products as well as the usage of them.

ACS, having already started providing samples to manufacturers in various fields, will manufacture products using these biosurfactants as early as this coming autumn. It is aiming to reduce manufacturing costs, and apply the biosurfactants to a wider range of technical fields, including environmental purification, taking advantage of the excellent detergency of the biosurfactants and their low impact on the environment.