Kenji Hata (Leader) and Don Futaba (Senior Research Scientist) of the Nano-Carbon Materials Team, the Research Center for Advanced Carbon Materials (Director: Sumio Iijima) of the National Institute of Advanced Industrial Science and Technology (President: Hiroyuki Yoshikawa) (hereinafter referred to as AIST), have succeeded in developing an aligned and highly densely packed carbon nanotubes material that retains the excellent physical and chemical properties of individual single-walled carbon nanotubes.

Individual single-walled carbon nanotubes have excellent physical and chemical properties, but in most cases these properties are lost in bulk materials comprising many single-walled carbon nanotubes. This is because the nanotubes are damaged when fabricated into bulk materials through processes such as dispersion, refinement and pressing.

The newly developed carbon-nanotube solid consists of aligned, highly pure, very long, single-walled carbon nanotubes, that are combined in a manner similar to rice ears, and it retains the desirable properties of single-walled carbon nanotubes in terms of their electrical conductivity, specific surface, and flexibility. The material can be designed in various shapes depending on the application. It is suitable for use in various applications, such as heaters, or applications requiring compact and flexible energy-storage materials. In particular, capacitors that use this packed single-walled carbon nanotubes as the electrode material possess higher energy densities and power densities than conventional capacitors that use activated carbon as electrodes. Results of this research have confirmed that carbon nanotubes are the key technology for realizing the next generation capacitors.

These research results were published in the online version of the British science journal Nature Materials on November 26, 2006 (GMT) under the title “Shape-engineerable and highly densely packed single-walled carbon nanotubes and their application as super-capacitor electrodes.”

|

|

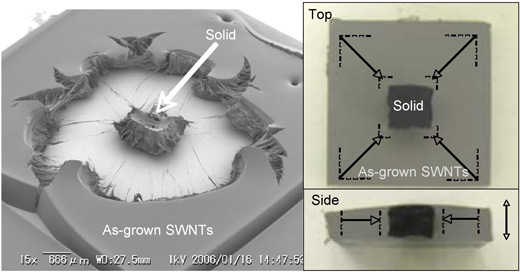

Figure 1: Carbon nanotube solid fabricated from carbon nanotube forests |

A single-walled carbon nanotube is a carbon material with unique properties, such as a high electrical conductivity, flexibility, anisotropy, and low dimensionality. This explains why it has attracted considerable attention as a potential material for manufacturing the next generation nanodevices and why it is expected to be a basic material at the core of nanotechnology in the 21st century.

To make the best use of the excellent possibilities of single-walled carbon nanotubes, it will be necessary to form and process them into dense materials that are capable of being handled without impairing their properties such as an excellent electrical conductivity, flexibility, and thermal conductivity. Conventional fabrication processes in which carbon nanotubes are dispersion in a solvent, refinement, and forming into shapes are widely used, but are incapable of making the best use of the properties of the original material, not only because nanotubes are difficult to disperse, but also because they become damaged during the fabrication process.

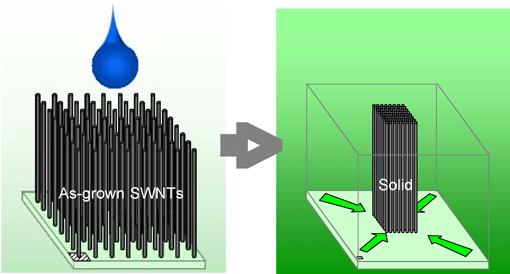

AIST has been working energetically on the development of technologies for forming and processing carbon nanotubes fabricated by the super-growth method which is the world’s best growth efficiency published in 2004, with a view to applying the resulting techniques to the various products. Kenji Hata, Don Futaba and other researchers discovered that single-walled carbon nanotubes in the form of a forest grown by the super-growth method produce a vertically aligned structure as a result of a zipping effect when they are immersed in a solvent and dried. The zipping effect is caused by the surface tension of the solvent and the van der Waals forces between the carbon nanotubes and it aligns the nanotubes into a dense array, like a bundle of rice ears. The result is a packed carbon nanotube material.

|

|

Figure 2: Densifying Single-walled carban nanotube as-grown forest (left) by liquid-induced collapse into a Single-walled carban nanotube solid (right).

|

This research was conducted with the support of the Nanotechnology Program “Project to Create Products through Application of Nano-Carbon” (2002–2005) and the Nanotechnology Program “Carbon Nanotube Capacitor Development Project” (2006–2010), both of which are sponsored by the New Energy and Industrial Technology Development Organization (hereinafter referred to as NEDO).

|

|

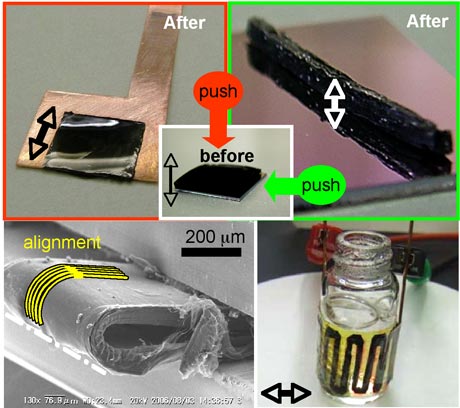

Figure 3: Shape-engineerable shape: Single-walled carban nanotube solid engineered into a flattened solid sheet (upper left) and rigid bar (upper right). Demonstration of the flexibility of the solid sheet (lower left) and application as a flexible heater (lower right).

|

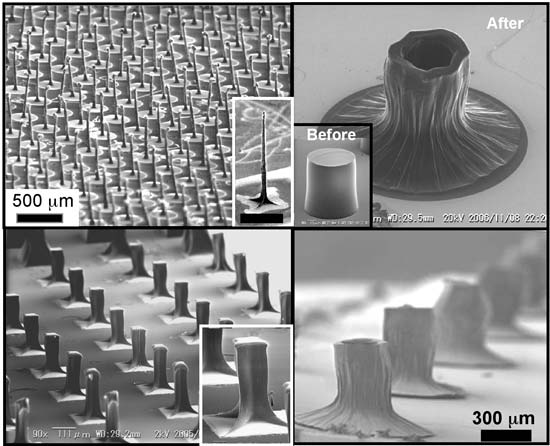

Vertically aligned carbon nanotubes synthesized by the super-growth method were used as starting materials. The single-walled carbon nanotubes in the structure have a length of 1 mm or longer, a high specific surface of greater than 1,000 m2/g and a carbon purity of 99.9% or higher, and are aligned. The as-grown carbon nanotubes are a low-density material which only occupy 4% of the forest volume; it is therefore difficult to use this material for a range of applications. The carbon nanotube forest loses its structural properties if it is dispersed into a liquid and processed by conventional methods. Consequently, Kenji Hata, Don Futaba and other researchers reviewed a technology for highly densifying a forest without damaging the structural properties thereof and discovered that, when a vertically aligned structure is immersed in a solvent and dried, the zipping effect to draw nanotubes together is caused by the surface tension of the solvent and the Van der Waals forces between the carbon nanotubes. The zipping effect aligns the nanotubes into a dense array (0.5 g/cm3 or more), like a bundle of rice ears. The resulting material can be formed in various shapes, such as sheet-like and bar-like shapes, by the application of a very weak external force during the process. Because neither dispersion nor refinement is used during the process, it is possible to form and process carbon nanotubes for density growth without damaging them. The resulting carbon nanotube solid thus retains the original properties of single-walled carbon nanotubes, such as a high specific surface of 1,000 m2/g, an electrical conductivity of 1Ω/□, and, in the case of sheet-like shapes, sufficient flexibility to permit extreme bending. In addition, as a result of the densification process the material shows a 70 times increase in Vickers hardness similar to that of graphite. The packed carbon nanotubes are more than 1 mm long and have a carbon purity of 99.9% or higher; they also retain the desirable alignment properties of the nanotubes forest. This solid should be suitable for various applications, including heaters that require compact and flexible energy-storage materials. A capacitor with the carbon nanotubes solid as an electrode material has been proved to have a higher energy density and power density than a conventional capacitor with activated carbon as an electrode.

|

|

Figure 4: Carbon nanotube solid formed into various shapes from lithographically patterned catalyst islands.

|

With the support of the Carbon Nanotube Capacitor Development Project, sponsored by NEDO, we aim to develop the technology on an industrial basis to mass-produce the nanotube forests (vertically aligned structures) that form the raw material for the carbon nanotubes solid. Within a few years, in collaboration with Zeon Corporation, we hope to mass-produce bulk single-walled carbon nanotubes solid. At the same time, we will develop a carbon nanotube capacitor that uses the carbon nanotube solid synthesized by this method as the material for its electrodes; such an electric double-layer capacitor should be capable of a high output and a high energy density with long life.