– Establishment of environment-friendly manufacturing technology using flow organic synthesis –

Researchers) ICHITSUKA Tomohiro, Researcher, (currently the Research Institute for Chemical Process Technology), KOUMURA Nagatoshi, Leader, and KOBAYASHI Shū, Joint Appointed Fellow, Flow Chemistry Team, Interdisciplinary Research Center for Catalytic Chemistry, and SATO Kazuhiko, Director of the center

- Development of continuous synthesis technology using flow fine synthesis for fine chemical intermediates

- Enables to greatly reduce CO2 emissions and chemical wastes compared to conventional synthetic methods

- Expected to be a key technology for returning to domestic production of fine chemicals

Flow organic synthesis technology for fine chemical intermediates

Most of fine chemicals have been synthesized by the batch method based on the conventional synthetic organic chemistry. The economic and environmental burdens of disposing chemical wastes such as by-products and solvents increase as the scale increases, so the manufacturing of fine chemicals is highly depended on overseas productions. In contrast, continuous synthesis using the flow method, which has various advantages such as high efficiency, cost saving, and space saving, has been used to manufacture bulk chemicals such as petrochemicals. However, since fine chemicals with complicated chemical structures such as pharmaceuticals are synthesized through the complicated multi-steps process, the application of the flow method to produce fine chemicals has been considered technically difficult. Despite that, pioneering examples of “flow organic synthesis” to produce fine chemicals have recently been reported, and expectations are increasing for industrial manufacturing of fine chemicals by the flow organic synthesis.

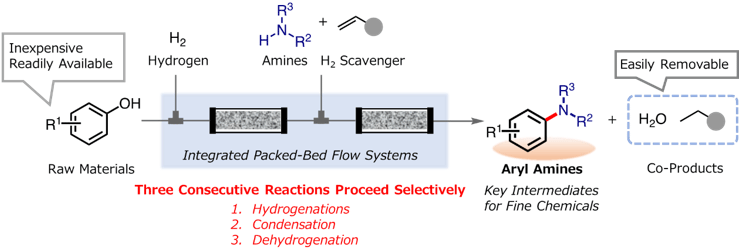

The researchers have developed a continuous flow synthesis technology for preparing aryl amines, which are important synthetic intermediates for fine chemicals.

The conventional synthesis method for aryl amines requires the use of expensive raw materials and generates large amounts of by-products. The developed technology is based on fine synthesis of organic compounds under the continuous-flow condition. The integrated flow system that consists of two column reactors containing heterogeneous catalysts has been designed. Under the optimized conditions, inexpensive and readily available starting phenols and amines were efficiently converted into the desired aryl amines, with only small amounts of easily removable co-products (i.e., water and hydrocarbons). The developed environmentally benign technology would be applied to actual manufacturing to significantly reduce CO2 emissions and waste, and also lead to a return to domestic production of important fine chemicals.