– Drastically increase the efficiency of non-destructive inspection of industrial infrastructures –

Researchers: FUJIWARA Takeshi, Researcher, Radiation Imaging Measurement Group, and KATOU Hidetoshi, Senior Researcher, X-ray and Positron Measurement Group, Research Institute for Measurement and Analytical Instrumentation, and SUZUKI Ryouichi, Prime Senior Researcher of the institute

- Sensitive area has been enlarged and X-ray sensitivity has been improved for infrastructure inspection.

- Combination with a battery-powered X-ray source enables X-ray inspection up to 10 cm thick iron objects.

- Infrastructure inspection can be performed with lower radiation doses and increased efficiency, which contributes to realization of a safe and secure society.

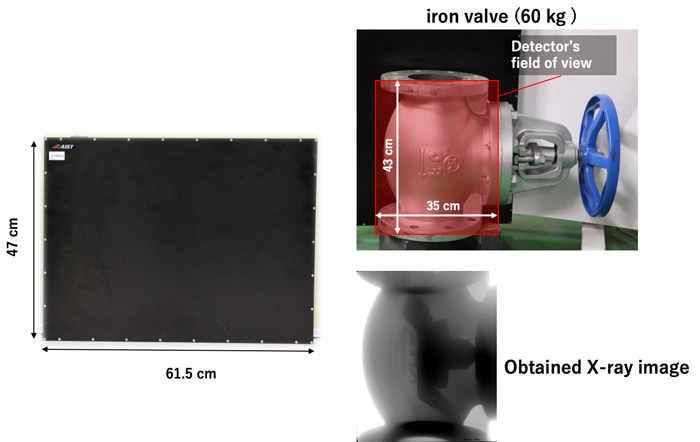

Detector’s field of view (upper right) and X-ray image (lower right) taken with the developed X-ray imaging device (left)

Digital X-ray imaging enables users to obtain X-ray images rapidly like a digital camera. Therefore, digital X-ray imaging became commonly used for medical applications and industrial inspection.

However, since infrastructures are mainly thick and heavy, the X-ray transmission rate becomes extremely low. In addition, conventional X-ray imaging devices do not have enough sensitivity and these factors make it difficult to apply digital X-ray inspection to heavy infrastructures. Therefore, today’s infrastructure inspections are mainly carried out with a large-size X-ray generator and X-ray films (or imaging plates). As a result, X-ray inspections required much effort and time for inspectors.

The researchers have developed a new digital X-ray imaging device that enables digital inspection of infrastructures. A new X-ray imaging detector were developed with large field of view. The effective area was enlarged to 43 cm × 35 cm (8M pixels). The developed X-ray imaging device can be driven with batteries. In addition, the combination with battery-driven compact X-ray source developed by AIST enables on-site non-destructive inspection of structures made of iron up to 10 cm thick. Furthermore, digital images can be acquired and checked in real-time, which makes the inspection of large-scale industrial infrastructures more efficient. These developed technologies are expected to be used for aging infrastructure inspection and contribute to a safe and secure society.