– High efficiency achieved in different module configurations by creating nanostructures –

Researchers: Ohta Michihiro, Senior Researcher, Jood Priyanka, Researcher, and Yamamoto Atsushi, Leader, Thermoelectric Energy Conversion Group, Research Institute for Energy Conservation

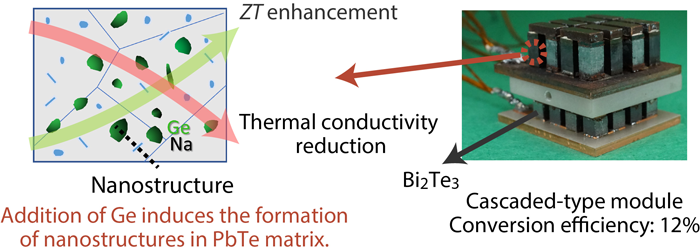

The researchers have demonstrated high thermoelectric performance by adding germanium (Ge) to a sintered lead telluride (PbTe) material to form nanostructures, in collaboration with Mercouri G. Kanatzidis (Professor at Northwestern University and Senior Researcher at Argonne National Laboratory). This material was further used in the fabrication of one-stage and cascaded (two-stage) thermoelectric modules, leading to high conversion efficiency.

|

|

Thermoelectric figure of merit in material and conversion efficiency in module were dramatically enhanced through nanostructuring. |

The researchers embedded nanostructures that allow heat to be scattered and electrons to flow through, by adding magnesium to a PbTe-based thermoelectric material, and achieved a thermoelectric figure of merit (ZT) of 1.8 in 2015. They developed a diffusion barrier that can be connected to the thermoelectric material and developed a segment-type thermoelectric module with an efficiency of 11%.

The researchers successfully formed 5 - 300-nm nanostructures by adding Ge, which is stable in the air, to PbTe. The nanostructures allow electric current to flow through and result in low heat conduction. The ZT of the nanostructured PbTe material reached a high value of 1.9 at 530 ˚C. They have developed a cascade-type thermoelectric module by stacking the nanostructured PbTe module on the hot side of a Bi2Te3 thermoelectric module. They achieved a conversion efficiency of 12%, which is a great improvement from the commercially available modules.

The researchers will further increase the conversion efficiency of the nanostructured PbTe module, examine its long-term stability, and conduct verification tests on the module. With a view of future market growth, they will develop alternative materials with the aim of replacing lead, the use of which is restricted, with environment friendly elements such as copper.