The researchers have developed a simplified method of measuring the Seebeck coefficient. Compared to the conventional method, the measurement time has been reduced by 90 % and its accuracy has been improved five-fold. The developed method is expected to be used for searching for new materials.

|

|

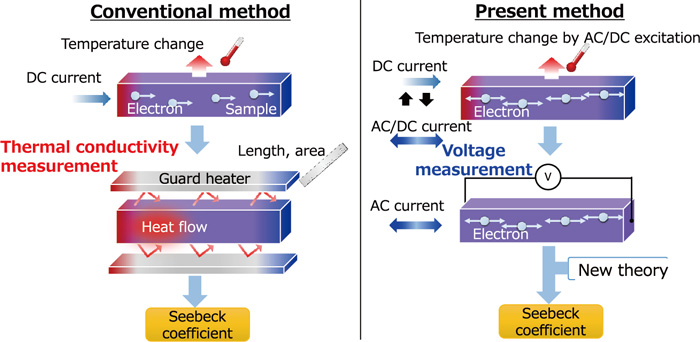

Conventional (left) and new (right) methods for measuring the Seebeck coefficient |

Thermoelectric materials have potential for use in converting thermal energy that is difficult to use effectively, such as waste heat, into electrical energy. In the conventional method, the thermal properties of a sample are required to determine its Seebeck coefficient. Accurate measurement of the properties is time-consuming and requires complex measuring equipment. There was a need for methods that allow the Seebeck coefficient to be measured accurately in a simpler and faster manner.

In the developed method, both direct and alternating currents are supplied to the sample, and temperature changes in the sample and the voltage at both ends of the sample are measured. The Seebeck coefficient is calculated by substituting the temperature and the voltage into a newly derived analysis equation. Unlike the conventional method, the new method does not require measurement of thermal conductivity or thermal emissivity. Consequently, the measurement time, which is about one day for each measurement in the conventional method, has been reduced to about one hour. It has confirmed that measurement accuracy is about 2 %, 1/5 of that with the conventional method.

The researchers will improve the system to allow measurements to be made over a wider range of temperatures. They will also develop software for automatic measurement and an easy to use measuring system.