Update(MM/DD/YYYY):01/24/2017

Development of Technology That Can Easily Calibrate Line Impedance Stabilization Networks (LISNs) Used in EMC Tests

- Contributing to the improvement in the efficiency of electronic equipment safety checks -

Points

-

Developed a technology that can easily calibrate LISN used for electromagnetic compatibility (EMC) tests

-

Significantly shortened calibration time by developing a specialized standard device that is optimal for calibration and by automating calibration

-

Will contribute to efficient implementation and improved reliability of conducted emissions tests

Summary

Ryoko Kishikawa (Researcher) and Masahiro Horibe (Leader), the Electromagnetic Measurement Group, the Research Institute for Physical Measurement (Director: Yasuhiro Nakamura), the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi), in collaboration with REPIC Corporation (REPIC; President: Atsumi Hayashi), have developed a technology that can easily calibrate line impedance stabilization networks (LISNs) used for conducted emissions tests, among electromagnetic compatibility (EMC) tests to check the safety of electronic equipment.

In conducted emissions tests, LISN is used to measure electromagnetic noise generated from electronic equipment, and it is required by international standards to calibrate the LISN itself beforehand in order to ensure the reliability of the measurement results. However, because multiple standard devices and complex data analysis are necessary for calibration of LISN, only specialized calibration laboratories and calibration corporations have been able to conduct calibration, requiring time and costs. In the present research, AIST and REPIC have developed the first specialized standard device suitable for calibration of LISN, and furthermore have simplified calibration procedures and realized an automatic calibration system. Thus, it is now possible to calibrate LISN easily in a significantly shorter time than before, even at EMC test sites. This development will lead to rapid and efficient implementation of conduct emissions tests and improvement in the reliability of the tests.

This technology will be presented by REPIC at TECHNO-FRONTIER 2016 to be held on April 20 - 22 at Makuhari Messe (Chiba, Chiba Pref.).

|

|

The developed specialized standard device (left) and the automatic calibration system |

Social Background of Research

Due to the explosive growth of electronic devices such as smart phones and computers, electromagnetic wave noise generated by such devices has caused malfunctions in other devices, and surrounding electromagnetic waves have influenced operation of these electronic devices, so countermeasures for these EMC problems are gaining attention. Recently, the needs of EMC tests are steadily increasing, as the application range has spread to new fields of technology, such as automobile equipment, LED products, and inverters built into large-scale solar power generation systems.

EMC tests include several types of tests, such as conducted emissions tests and radiation immunity tests, and the test methods are regulated by international standards of the International Special Committee on Radio Interference (CISPR) etc. In order to ensure the reliability of test results, it is necessary to calibrate test equipment in advance.

Impedance calibration of LISN, a type of test equipment used for conducted emissions tests, is usually conducted by comparing impedance of the LISN with the impedance of standard devices. It is desirable for the impedance of the standard device to have the same characteristics as those of LISN. However, until now there has been no standard device with the same impedance characteristics as those of LISN, so in actual calibration, three types of standard devices are used to compare with the LISN, and the calibration value was calculated from these results by complex data analysis. For this reason, calibration of LISN was primarily conducted by specialized calibration laboratories and calibration corporations, posing such issues as time, cost, and difficulty in on-site calibration.

History of Research

AIST has developed national standards for high-frequency impedance, and conducted research and development on design and evaluation technologies for high-frequency electrical circuits. REPIC holds advanced fabrication technology for high-frequency circuits. Therefore, by combining these techniques, AIST and REPIC aimed at developing a specialized standard device optimal for impedance calibration of LISN, which is a standard device that has the same impedance characteristics as those of LISN, and at realizing a method that can find calibration values easily just by comparing the LISN with the specialized standard device once. Based on this calibration method, they have also worked to develop an automatic calibration system for LISNs.

This research and development project was conducted with support from the Small and Medium Enterprise Agency under the manufacturing, commerce and service innovation project for small and medium enterprises (FY 2013).

Details of Research

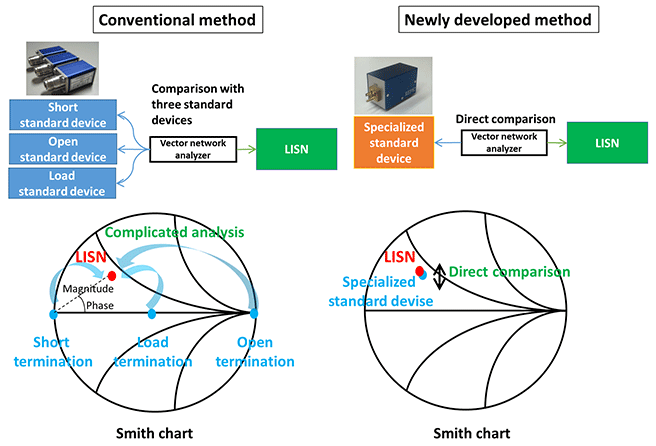

Impedance is expressed by two quantities, “magnitude” and “phase”. In conventional calibration methods, the magnitude and phase of LISN impedance was compared and measured with three types of standard devices (short standard device, load standard device, and open standard device) using a vector network analyzer (Fig. 1 top left), and the calibration value of the LISN was determined from these results by complicated complex number calculations (Smith chart, Fig. 1 bottom left). In contrast, the researchers developed a standard device that has impedance characteristics similar to those of LISN, and devised a method to conduct calibration by comparing the developed standard device with LISN just once (Fig. 1 top right). This eliminates the need for complicated complex number calculations, making calibration of LISN possible in a short time (Smith chart, Fig. 1 the bottom right).

|

Figure 1: Calibration principle of LISNs

Conventionally, three types of standard devices were used to show the calibration value of

those standard devices on a Smith chart, and the characteristics of the LISN were found from those

three values (bottom left), but in the developed calibration method, it is possible to compare directly,

because the specialized standard device and LISN have the same impedance characteristics (bottom right). |

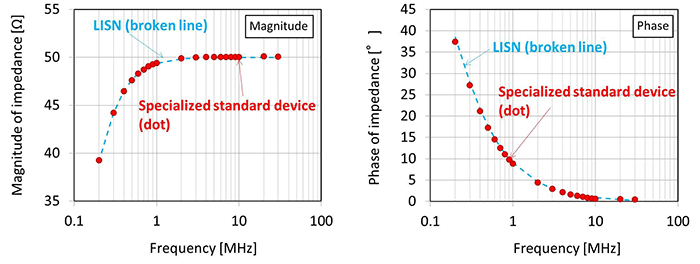

The developed specialized standard device was designed based on the impedance characteristics of LISN regulated by an international standard (CISPR 16-1-2), and is fabricated by precisely installing small electronic parts such as inductors, capacitors, and resistors. Considering the effect of minor inductance and stray capacitance resulting from electromagnetic interference between circuits and peripheral parts including connectors and housing of the standard device, the researchers selected parts and designed circuit patterns. Additionally, they analyzed and evaluated characteristics of the standard device in detail, and adjusted the circuit constants based on the results. It was confirmed that the standard device has impedance characteristics nearly the same as those of LISNs using the high-frequency impedance national standards at AIST (Fig. 2).

Based on the developed calibration technique, an automatic calibration system for LISNs was developed. With the conventional methods, each impedance calibration of LISN took about 20 minutes, but with the developed automatic calibration system, the time required for each impedance calibration is significantly reduced to approximately 90 seconds (less than one tenth of the conventional methods). Introducing this automatic calibration system using a specialized standard device to EMC test sites enables testers to conduct on-site calibration of LISNs. In the future, it is expected that conducted emissions tests using LISN can be conducted more quickly and efficiently.

|

|

Figure 2: Comparison of the impedance characteristics of the developed specialized standard device and LISN |

Future Plans

REPIC will evaluate the long-term stability of the LISN automatic calibration system including the specialized standard device, and advance commercialization. Also, AIST will expand the developed impedance calibration method using a standard device with characteristics resembling those of a measurement target, and conduct research and development of calibration methods suitable for impedance characteristics evaluation of power electronics semiconductor elements and equipment.