Manabu Yoshida (Leader) and Kazunori Kuribara (Researcher), the Printed Device Team, the Flexible Electronics Research Center (Director: Toshihide Kamata), the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi), and Yohei Hori (Senior Researcher), Yasuhiro Ogasawara (Researcher), and Toshihiro Katashita (Senior Researcher), the Electroinformatics Group, the Nanoelectronics Research Institute (Director: Tetsuji Yasuda), AIST, have developed security tag circuits that utilize the individual variations inherent to organic devices to make it difficult to counterfeit products.

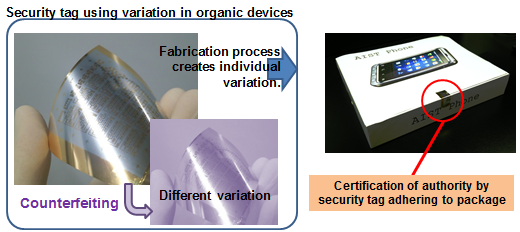

The developed circuits make full use of the small individual variations among organic devices that occur during the fabrication process to generate unique numbers that differ for each circuit of the same design. Using organic semiconductors that are highly stable in air and a hybrid insulating film that employs both organic and inorganic materials, the circuits can operate at a voltage as low as 2 V with a low error rate. The circuits can be fabricated on flexible substrates and, for example, can be adhered onto product packages as ID tags to prevent distribution of counterfeit products and tampering with the circuits themselves.

Details of this technology will be announced on January 27 to 29, 2016 at Printable Electronics 2016 to be held at Tokyo Big Sight.

|

|

The feature of the developed security tag circuit, and an illustration of its use on a product package |

Increase of counterfeit products of, for example, consumer electronics, brand-name merchandise and software in today’s society has been a major issue in recent years. According to the Japan Patent Office’s FY2014 Report on the Survey of Counterfeit Damages, the total value of the damage sustained in Japan by counterfeit products in FY2013 topped 110 billion yen. Furthermore, according to the results of survey questionnaire in the same report, more than 40 % of companies responded that the damage they have experienced in the overseas markets has increased year by year. Counterfeit products can cause not only financial loss and abasement of brand image but also serious accidents or incidents that threaten the security and safety of the society and daily life. Although some products already have unique IDs for traceability and/or authenticity, the problem remains that printed IDs such as bar codes and QR codes and even electrically recorded information in memory integrated circuits can still be copied and cloned. Therefore, there has always been the risk that counterfeit or pirated products are distributed as authentic goods in the market. Thus, the demand for the unclonable security tags to prevent counterfeiting and identify authentic products will increase in the near future.

At the same time, security circuits have become a necessity in many kinds of situations as the “Internet of Things (IoT)” continues to evolve. To implement security circuits in wide variety of IoT devices, the circuits should be fabricated using various materials ranging from conventional silicon to soft materials such as polymer films.

AIST has been conducting research and development of large-area flexible electronic devices and electronic devices with highly arbitrary shapes. One of its goals is the development of technology for print production processes and, to date, it has developed memory arrays and various large-area sensors that use printing technology. In recent years, it has been carrying out research to reduce operating voltage of flexible devices.

Techniques to generate numerical values intrinsic to circuits using the individual variations existing in devices were proposed for the first time in 2000, but so far it has been possible only to fabricate the circuits on substrates made of hard materials such as silicon. At AIST, researchers have been working on improving and evaluating the characteristics of “IC fingerprint” technologies that prevent unauthentic devices masquerading as authentic. AIST decided to combine the “IC fingerprint” technology and the low-temperature production process for flexible devices fostered at AIST to fabricate security tags that cannot be counterfeited onto soft plastic substrates.

Part of this research and development project was supported by the “Research and development of security tags using printed circuits which are not physically replicative (FY2015)” project in “Next-Generation Printed Electronics Material & Process Foundation Technology Development” of the New Energy and Industrial Technology Development Organization.

By combining organic semiconductors that have high air stability and a hybrid insulating film that employs organic and inorganic materials, AIST has developed a security tag whose operating voltage is 2 V. By using organic semiconductors, it has become possible to use individual variations in the orientation of the molecules, surface shapes, etc. that were not present in inorganic devices. The developed security tag uses oscillation circuits called ring oscillators, and by comparing the oscillation frequencies of two ring oscillators, a binary number of 0 or 1 is generated. If the design of the two ring oscillators is identical, the higher of the two frequencies is determined by the individual variations occurred during the production. Therefore, if multiple numbers of ring oscillators are fabricated inside the security tag circuits, unique binary values can be generated at random for each circuit.

|

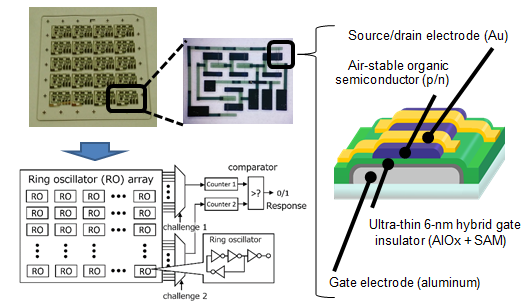

Figure 1: Photo showing ring oscillators fabricated on a glass substrate, enlarged view of security tag circuit (top left),

diagram of the entire security tag (bottom left), and schematic illustration of the structure of an organic transistor serving as the core (right) |

Figure 1 includes a photo of fabricated ring oscillators and a schematic illustration of the structure of the organic transistor. In the present research, external equipment was used for the selecting parts and the counter parts shown in the diagram of the entire security tag. However, organic devices have already realized these parts, and in the future, it will be possible to fabricate them concurrently with the ring oscillator circuits. First, the surfaces of aluminum gate electrodes of the organic transistors were oxidized using oxygen plasma to create thin films of aluminum oxide. Subsequently, the substrate was immersed in a solution of organic molecules (n-octadecylphosphonic acid) to form 2 nm thin films called a self-assembled monolayer on the aluminum oxide films by chemical reaction between the organic molecules and the aluminum oxide film. These two layers were used as the hybrid insulating films. Finally, the organic semiconductor layer and gold electrodes were deposited by thermal evaporation, and the transistor devices were formed. Dinaphthothienothiophene (DNTT, made by Sigma-Aldrich) was used for the air-stable p-type organic semiconductor, and a benzobisthiadiazole derivative (TU-1, made by Ube Industries) was used as the air-stable n-type organic semiconductor.

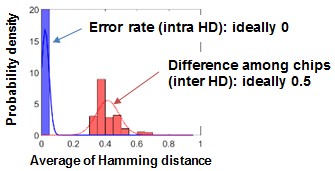

In general, it is difficult for organic semiconductors to achieve stable operation in air over long periods of time, and the probability (error rate) is high that errors where the wrong binary values will be generated. In view of this, semiconductor materials that are stable in air and hybrid insulating films were used. In regard to the n-type semiconductor, whereas existing copper hexadecafluorophthalocyanine (F16CuPc) tends to be reduced to a mobility of 50 % or so of the initial value after 10 days in air, the mobility reduction of TU-1 is only 7 % even after 212 days. This resulted in the improvement in the stability of the security tag circuits and the error rate under operating conditions was less than 10 % (Fig. 2). Furthermore, while the operating voltage was around 40 V for devices that use ordinary thick polymer films, by employing an extremely thin, 6-nm hybrid insulating film that uses the self-assembled monolayer and the aluminum oxide film, the operating voltage was reduced to 2 V. As a result, power consumption has been slashed, making it easy to use the developed security tag circuits for product packages onto which they are adhered and for the prevention of the counterfeiting of paper money and negotiable securities.

|

Figure 2: Variations in the error rate (Hamming distance inside chips) indicating the reproducibility of the numbers (blue) and

in the difference in the chip output (Hamming distance between chips) that indicates the uniqueness (red) produced by 2 V operation |

The researchers aim to improve production efficiency by combining the printing technology of AIST with the device fabrication process and advance the development of security tags having high intrinsic properties that take advantage of the individual variations inherent to the printing processes. In addition, to contribute to the creation of a safe and secure society using this organic security tag technology, they intend to develop highly reliable operating systems that include databases and certification servers.