- Contributes to high-precision measurement with a synthetic polymer of uniform molecular length -

Kayori Takahashi (Senior Researcher), the Particle Metrology Section (Section Chief: Hiromu Sakurai), the Nanomaterial Characterization Division (Division Head: Toshiyuki Fujimoto), the Metrology Institute of Japan (Director: Koichi Chiba) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi), and Shinichi Kinugasa (Manager), the Metrology Training Center, the Metrology Management Center of AIST, have developed a certified reference material (CRM) with a single degree of polymerization without distribution of molecular weight, even though it is an artificially manufactured synthetic polymer.

The development of this CRM has been achieved by the use of technology to separate synthetic polymer molecules by degrees of polymerization using supercritical fluid chromatography and the establishment of technology to efficiently fractionate the separated polymer molecules of a single degree of polymerization. The developed CRM is expected to contribute to precise molecular weight measurement of polymer materials and particle diameter measurement of nanoparticles. The developed CRM, poly(ethylene glycol) (23mer) [NMIJ CRM 5011-a] will be available for distribution beginning July 23, 2014 through contracted distributors.

|

|

Poly(ethylene glycol) (23mer) certified reference material to be available for purchase |

There are a lot of contemporary industrial products, such as pharmaceuticals and semiconductors, that are extremely precise and microscopic, where granting of advanced functions and nanometer-size processing is required. The manufacturing and R&D fields using synthetic polymer materials are reaching the stage at which molecular-level control is becoming necessary. In many materials produced by living organisms, such as DNA, the length of the molecule is uniform to exert extremely precise functions, even if their molecular weight may be large. In the field of synthetic polymers, there are expectations for the expression of even more focused physical properties through the accurate control of molecular length and narrowing of molecular weight distribution. However, in most cases, it is still difficult to synthesize artificial polymers with uniform molecular weight, leaving plenty of room for technical breakthrough.

Reference materials of synthetic polymers have been available from metrology research institutions around the world. However, until now, all were of a state with a distribution in molecular weight, or in other words, a mixture of molecules with different degrees of polymerization. In order to respond to the need for high-precision and micronizing in the fields of manufacturing and R&D of polymer materials, reference materials consisting entirely of uniform molecular weight polymers are required to improve the accuracy of polymer measurement.

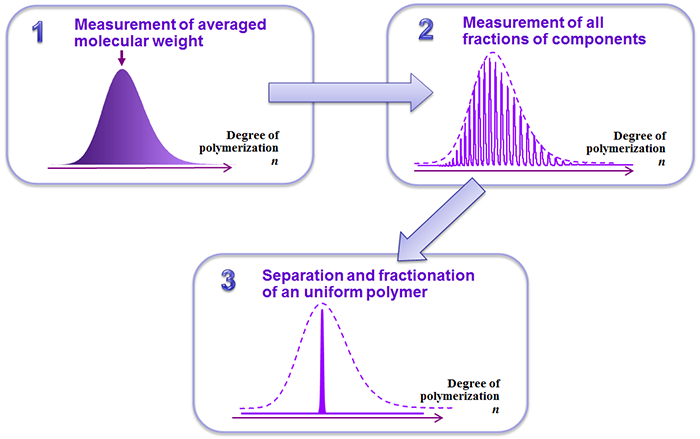

AIST has been distributing approximately ten types of reference material based on poly(ethylene glycol) and polystyrene, in which their molecular weight has been given as a certified value. Where other countries only provide average and representative molecular weights as values (Fig. 1-1), reference materials by AIST provide the component values of all polymer molecules included (i.e., the state of molecular weight distribution) as certified values (Fig. 1-2). This being the case, they can be used for calibration and validation of equipment to measure not only the average molecular weight, but also the width of the distribution, such as various chromatographs and mass spectrometers.

However, high-precision calibration of measuring equipment of unknown characteristics, using a reference material with a molecular weight distribution is not necessarily easy. Because detection sensitivity for each molecular weight will differ according to the measuring equipment, molecular weight distribution measurement will differ when different equipment is used. In order to compare the value measured by the measuring equipment with the molecular weight distribution attached to the reference material, the characteristics of the detector must be checked in advance and the measured value of molecular weight distribution must be corrected, but generally, this kind of correction is very complicated and has significant uncertainty. In order to solve this problem, AIST has been conducting the development of reference materials without variance in molecular weight as indicated in Fig. 1-3, which enables direct measurement of molecular weight and other various physical properties accurately, without correction.

|

|

Figure 1 : Schematic diagram of the process to produce a polymer reference material of a single degree of polymerization |

Poly(ethylene glycol) is one of the few synthetic polymers that is water-soluble and can be orally ingested. It is used in many applications, such as pharmaceuticals and daily goods. Recently, it is being used in materials that require precise molecular weight control, as a modifier for proteins and as a base material for drug delivery systems, and the need as a reference material is high. A reference material of poly(ethylene glycol) with a single molecular weight has been developed in this research.

In conventional polymerization from low-molecular-weight compounds, it was difficult to obtain polymers with a single molecular weight because byproducts could not be completely suppressed. The developed reference material has been achieved by using a technology to separate only molecules of a specific degree of polymerization from a commercially available sample using supercritical fluid chromatography and the development of a system to automatically collect the separated molecules of a single degree of polymerization efficiently. The development of the fractionation system of supercritical fluid chromatography was conducted in cooperation with Japan Spectroscopic Corporation.

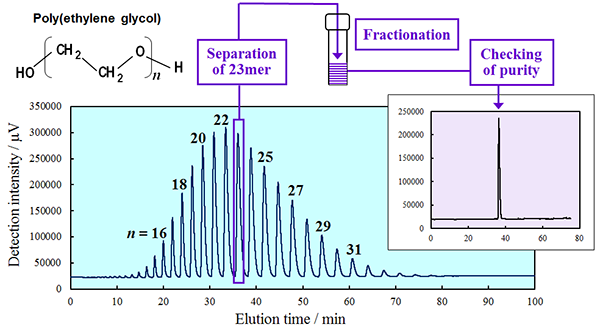

An example of separation of a commercially available poly(ethylene glycol) with an average molecular weight of approximately 1000 (approximately 23 when converted to the degree of polymerization) by supercritical fluid chromatography is shown in Fig. 2. Carbon dioxide with accurately controlled temperature, pressure, flow rate, etc. was used as the supercritical fluid, with interaction between the column packing material and poly(ethylene glycol) appropriately adjusted, to separate polymer molecules of the desired degree of polymerization from the sample in which many components of different degrees of polymerization were present. The portion enclosed in the square in Fig. 2 is the part for polymer molecules with a degree of polymerization of 23, and only the molecules included here were fractionated and refined to obtain poly(ethylene glycol) of a single degree of polymerization (23mer). Since the molecular weight of the repeating unit of poly(ethylene glycol) is 44 and the molecular weight per single degree of polymerization is smaller than 104 for polystyrene or 254 for polycarbonate, the optimization of separation conditions was very important to separate the polymer molecules for each degree of polymerization. The mass fraction of poly(ethylene glycol) 23mer, the developed reference material had high purity of 0.998 ± 0.002 (kg/kg), taking into consideration the expanded uncertainty. Furthermore, poly(ethylene glycol) reference material other than 23mer can also be developed using the developed technology. In addition, it can also be applied to various polymers other than poly(ethylene glycol).

The developed CRM has a single degree of polymerization as indicated in Fig. 1-3, and since it does not have any molecular weight distribution shown in Figs. 1-1 and 1-2, it will contribute to improving the accuracy of various measurements of polymers. For example, it will enable calibration, validation, and resolution assessment of molecular weight measuring equipment for polymers with high-precision. In addition, it can also be used as a particle size reference for nanoparticle measurement. Furthermore, in the measurement of viscosity, density, refractive index, and other physical properties, correction for molecular weight distribution will not be necessary, thereby allowing high-precision data to be obtained without the uncertainty accompanying conversion for physical properties where its dependence on molecular weight is not clear.

|

Figure 2 : Example of separation of poly(ethylene glycol) by supercritical fluid chromatography

(n indicates the degree of polymerization) |

The developed reference material will be available on July 23, 2014 as Certified Reference Material: NMIJ CRM 5011-a Poly(ethylene glycol) (23mer).