Update(MM/DD/YYYY):09/21/2012

Intermolecular Space Evaluation Using Slow Positrons Extracted into the Atmosphere

- In-situ evaluation of functional thin films such as desalination membranes -

Points

-

A technology has been developed to form positrons into a focused beam and to control their energy to allow the beam to be used in actual environments.

-

The intermolecular spaces in a polymer thin film with a thickness of several hundred nanometers in an ambient gas with controlled humidity were analyzed.

-

The technology is expected to be applied to the reliability evaluation of stacked-thin-film functional materials used in nanotechnology.

Summary

Nagayasu Oshima (Senior Researcher), Advanced Defect-Characterization Research Group, the Research Institute of Instrumentation Frontier (Director: Masataka Ohkubo) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Tamotsu Nomakuchi), Kenji Ito (Section Chief), Nanostructure Material Characterization Section, Nanomaterial Characterization Division, the Metrology Institute of Japan (Director: Koichi Chiba) of AIST, and others have developed a controlled-environment positron probe micro-analyzer. This system can be used with the positron annihilation lifetime technique to evaluate open spaces such as atomic- and molecular-level defects, holes, and pores in functional thin films in an ambient gas at atmospheric pressure that is controlled as an actual environment.

In this system, positrons (antiparticles of electrons) are generated in a vacuum using an electron linear accelerator and formed into a brightness-enhanced, focused, short-pulse beam with low, variable energy. The beam is extracted via a vacuum window into the atmosphere. The nanoscopic open spaces in a sample are evaluated in the following way. The positron beam is irradiated onto the sample surface and positrons are injected into a limited region near the surface. The time to annihilation (i.e. the lifetime) of the positrons or positronium in the sample is measured to evaluate the size of the open spaces. By using this system, nondestructive evaluation of the intermolecular spaces in a polymer thin film with a thickness of a few hundred nanometers in a nitrogen atmosphere with controlled relative humidity has been achieved.

The properties of thin polymer films are generally dependent on the atomic- or molecular-level spatial structures of the films. The developed technology allows the analysis of such spatial structure of a thin film in actual environments. The technology is expected to contribute to improvements in evaluation techniques for the environmental-response performance of functional thin films used in nanotechnology etc.

Details of this technology will be published online in Applied Physics Letters, an American scientific journal, on July 3, 2012 (JST).

|

|

|

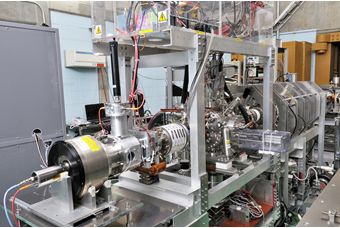

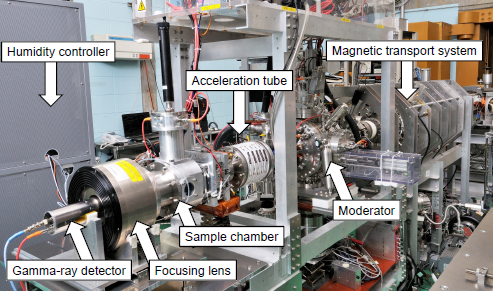

(Figure) : Controlled-environment positron probe micro-analyzer (left) and schematic of the extraction of positrons into the atmosphere (right) |

Social Background of Research

The properties of a material, such as its mechanical strength, electrical insulation, and molecular permeability, depend not only on the composing elements of the material, but also on the structure of its interatomic and intermolecular spaces (i.e. its atomic- and molecular-scale spaces, or nanospaces). In the field of nanotechnology, functional materials are often developed by possessing the desired properties through surface treatment or thin film formation. To research and develop these materials, it is important to accurately analyze their surface region.

The lifetimes of positrons and positronium in a material are correlated with the sizes of open spaces such as defects, holes, and pores, so that those sizes can be evaluated by measuring positron and positronium lifetimes. Positron and positronium lifetime measuring systems, which use a slow positron beam suitable for analyzing surfaces and thin films, have been developed on the basis of this principle. Because positron beams are generally produced in high-vacuum chambers, these systems do not allow evaluation of a material in ambient gas at atmospheric pressure. To overcome this, research institutions in various countries have attempted to develop techniques for extracting positron beams into the atmosphere. The extracted positrons, however, can not be controlled to have sufficiently low energy so as to be injected into the surface region or specific depth in samples. There was therefore a need for a technique to extract a slow positron beam into the atmosphere and measure the lifetimes in order to characterize thin films in ambient gas.

History of Research

AIST has conducted research and developed methods for generating a high-intensity positron beam with an electron linear accelerator and systems for accurately measuring the lifetimes of positrons and positronium. Using a highly efficient focusing technology, techniques for generating a focused, high-intensity short pulse positron beam, measuring the lifetimes of positrons and positronium in a micro-region (several tens of micrometers), and imaging near-surface nanospace distribution have been developed (AIST press release on August 28, 2008). In the present study, in order to analyze materials in an actual environment, techniques for extracting a focused positron beam at the desired speed (energy) into the atmosphere and controlling humidity in the sample chamber have been developed, aiming at a system for measuring positron and positronium lifetimes.

The technique for extracting a slow positron beam into the atmosphere was developed in collaboration with Tokyo Institute of Technology. It was supported by FY2009–2011 Grants-in-Aid for Scientific Research (B) “Development of an Atmospheric Positron Microscope” from the Japan Society for the Promotion of Sciences. The development of a technique for measuring positron and positronium lifetimes in a sample in an actual environment was supported by “Development of Nanoporosimetry for Separation Membranes based on a Positron Beam and Evaluation Method of Membrane Performance,” a FY2009–2012 sub-project of “Water Saving and Environmentally-friendly Water Recycling Project/Development of an Elemental Technology for Water Recycling/Development of an Innovative Membrane Separation Technology” commissioned by the New Energy and Industrial Technology Development Organization.

Details of Research

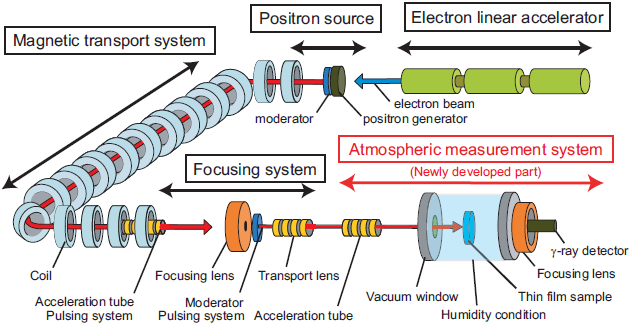

Figure 1 shows the developed controlled-environment positron probe micro-analyzer. The key was the development of a technique for efficiently extracting a slow positron beam suitable for analyzing thin films into the atmosphere. Unlike with the electron beams used in an electron microscope, it was not possible to cut and form the positron beam using aperture stops, because only very limited numbers of positrons are generated at any one time. For this reason, conventional techniques use a relatively large beam. Therefore a vacuum window for extracting the beam into the atmosphere becomes large and it must be made of thick material to keep it strong. The speed of the positrons must be increased to enable the positron beam to pass through the thick vacuum window. However, such a high-speed positron beam will pass through a thin film sample, making it impossible to measure the lifetimes of positrons and positronium within the sample (Fig. 2).

|

|

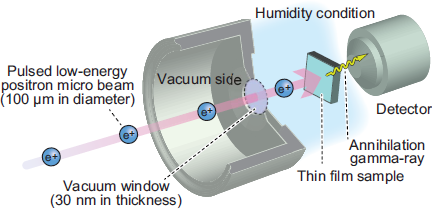

Figure 1 : Schematic of the controlled-environment positron probe micro-analyzer

Electrons from the electron linear accelerator are sent to the positron generator and the generated positrons are formed into a focused short-pulse beam by the focusing lens, the positron moderator, and the pulsing system. The beam is extracted into the environment at atmospheric pressure through the vacuum window. |

|

|

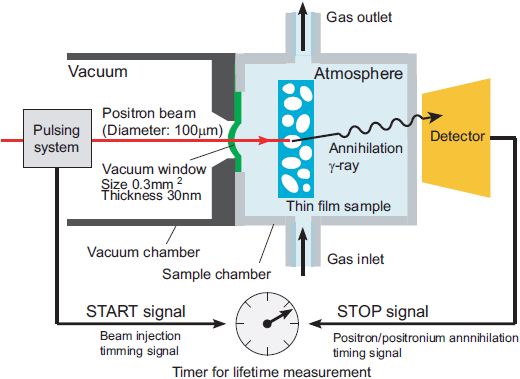

Figure 2 : Schematic of the method used to extract the slow positron beam into the atmosphere |

To extract the slow positron beam into the atmosphere, the thickness and size of the vacuum window have been reduced and a technique for generating a focused beam that can pass through the small window with minimal reduction in the number of positrons has been developed. In addition, a system for measuring positron and positronium lifetimes has been realized by integrating and optimizing elemental technologies, including: (1) a technique for making the focused positron beam into short pulses; (2) a technique for accurately controlling the positron injection position; and (3) a technique for highly reliable lifetime measurement in actual environments (Fig. 3).

|

|

Figure 3 : Controlled-environment positron probe micro-analyzer |

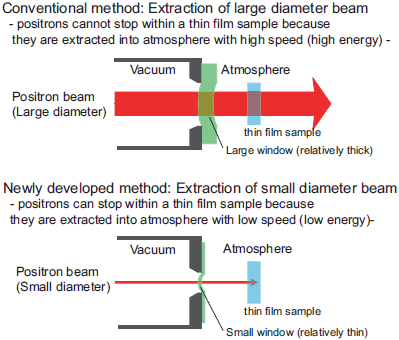

In this system, a positron beam (diameter 10 mm) is generated by the electron linear accelerator. The beam is then focused to a diameter of about 100 μm and formed into short pulses by using the focusing lens, the positron moderator, and the pulsing system. The focused short-pulse beam is directed at a silicon nitride vacuum window (0.3 mm2 in area) by controlling the trajectory of the beam and is thus extracted into the atmosphere. Because the vacuum window is as thin as 30 nm, it allows a slow positron beam suitable for evaluating a thin film to pass through. Positron and positronium lifetimes are determined from the difference between the time of formation of the positrons into pulses (the start time) and the time of detection of the annihilation gamma rays emitted when the positrons and positronium are annihilated. Different gases can be introduced into the sample chamber, making it possible to simulate different service environments (Fig. 4). When a thin film is placed in the chamber, the sizes of atomic- and molecular-level spaces can be determined by measuring the times to annihilation of the positrons and positronium in the thin film and the nanospace structure of the thin film in a service environment can be evaluated.

|

|

Figure 4 : Schematic of the controlled-environment measuring unit |

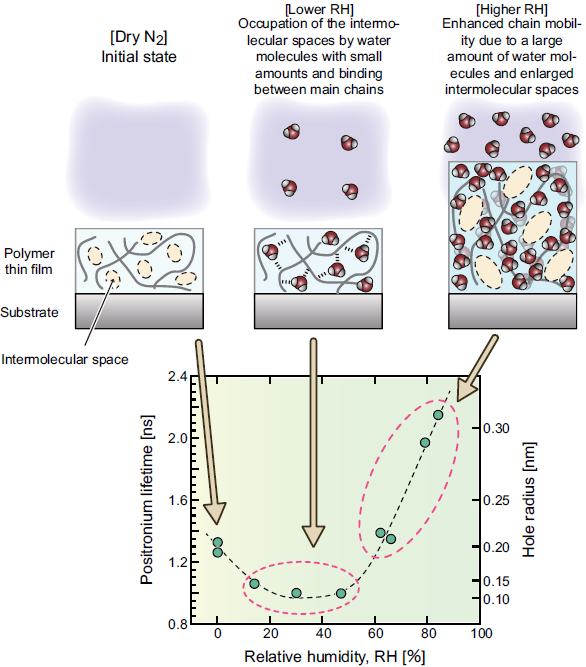

As one example, the system was used to evaluate the humidity dependence of the intermolecular spaces in a polyvinyl alcohol (PVA) thin film. PVA thin films are practically used as basic materials for gas barrier layers of displays and functional layers in molecular separation membranes; their nanohole structures therefore need to be evaluated. A PVA thin film (about 400 nm thick) spin-coated on a silicon substrate was placed at the air-side of the vacuum window, and the positron penetration depth was set to the thickness of the thin film. Lifetimes of positrons and positronium were measured while the relative humidity of the nitrogen introduced into the sample camber was changed from 0% to 90%. Figure 5 shows the humidity dependence of the positronium lifetime and the hole radius calculated from the positronium lifetime. In low-humidity environments the PVA thin film absorbed only a small amount of water molecules, and the hole radius in the film decreased from 0.2 nm to 0.1 nm with increasing the relative humidity to ~40%. As the humidity increased, the amount of absorbed water molecules increased and the hole radius increased to 0.3 nm. The results demonstrate that the humidity-dependent changes in the intermolecular spaces in the PVA thin film are quantified nondestructively.

Techniques for evaluating the reliability of various functional materials in the areas of environmental technology, nanotechnology, and manufacturing technology can be improved by applying the developed positron system to the environmental response analysis of stacked thin materials, such as seawater desalination membranes and display protection films.

|

|

Figure 5 : Example of analysis of responses of intermolecular spaces to changes in humidity, as obtained by measurement of positron and positronium lifetimes using the developed system |

Future Plans

Currently, the researchers are developing a technique for increasing the intensity of the positron source so as to improve measurement efficiency. They intend to improve the technology and put it to practical use in a common use facility.