- A step toward X-ray nondestructive inspection and Röntgen examination using dry batteries as a power source -

Ryoichi Suzuki (Leader), the Advanced Defect-Characterization Research Group, the Research Institute of Instrumentation Frontier (Director: Yoshio Akimune) of the National Institute of Advanced Industrial Science and Technology (AIST) (President: Hiroyuki Yoshikawa), In cooperation with Dialight Japan Co., Ltd. (President: Masanori Haba) and Life Technology Research Institute, Inc. (President: Yoshihisa Ishiguro), has developed practical portable X-ray sources with a cold-cathode electron source using carbon nanostructures.

The X-ray sources use carbon nanostructures as field-emission electron sources, and can promptly generate X-rays whenever required because as it does not have a heater or a filament, it does not require preheating. As energy is consumed only while X-rays are being generated, X-rays with an energy of >100 keV--the level needed in nondestructive inspection or medical diagnostics--can be generated from dry batteries or a USB power source. The technology also is applicable to an electron beam with a power of >10 kW generating X-rays for ultrahigh-speed imaging, which contributes to new applications that require ultra-rapid X-ray inspection.

The result of the study will be published at the "Symposium on Advanced Material and Nondestructive Measurement Technology for Realizing a Safe and Secure Society" to be held from March 24 to 25, 2009.

|

|

|

Main body of the developed X-ray source (left) and an X-ray transmission image (right, bottom) |

X-ray measurement systems are currently used in many areas, including medical diagnostics, nondestructive inspection of structures, inspection of industrial products, and security checks at airports, and will find new applications during the process of realizing a safe and secure society. In conventional X-ray sources, electrons, which hit an anode to emit X-rays, are emitted from a cathode heated by a heater or a filament. As it takes time for a cathode to reach the required temperature, this requires a warm-up period, and the heater thus continually consumes power, even when X-rays are not generated. There is the additional problem of heater/filament degradation caused by prolonged current conduction. As a result of this warm-up time and heavy power consumption, applications for X-ray measurement systems are limited--particularly in nondestructive inspection and medical diagnostics areas--where portability is most valuable.

The Research Institute of Instrumentation Frontier worked on energy-saving electron accelerators and on applications for high-energy X-rays. An electron accelerator and a high-energy X-ray generator were developed using dry batteries in 2007 (AIST press release, October 22, 2007), and the Institute has since been working on improving the start-up time of the X-ray source and overall energy efficiency.

Dialight Japan Co., Ltd. has succeeded in developing cold-cathode electron sources using carbon nanostructures with a very high electron emissivity, and has been working in cooperation with Life Technology Research Institute, Inc. in applying the cold-cathode to X-ray sources.

Expecting that a new high-energy X-ray source could be best realized by combining the groups' technologies, the challenge to X-ray nondestructive inspection systems started in 2008 by adopting high-performance cold-cathode technology using carbon nanostructures, under the "Industrial technology research and development operations (for supporting small- and medium-sized enterprises)."

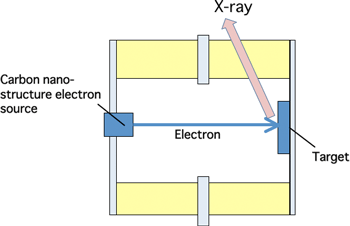

The main body of the developed X-ray source (X-ray tube) is a metal-ceramic tube sealed by metallic and ceramic materials, and two types, a low-power tube and a high-power tube, have been developed (Fig. 1). In these X-ray tubes, a negative voltage is applied to the electron source using carbon nanostructures, and a positive voltage is applied to the target; electrons emitted from the electron source hit the target and generate X-rays. The two types of developed X-ray tubes can generate X-rays with a maximum energy >100 keV. The carbon-based cold-cathode electron source emits electrons by field emission, even at room temperature. A known problem is that field emission gradually degrades through exposure to a high electric field, as in an X-ray tube. To avoid the problem, the configuration of the electron source using carbon nanostructures and the fabrication conditions are optimized, and processing techniques are developed to stabilize electron emission. As a result, long life, which causes no problems in normal use, is achieved. Furthermore, the X-ray tube is combined with a high-voltage power source using dry batteries so that energy is consumed only while X-rays are being generated. Thus, a high-energy X-ray source using two AA batteries or a USB power source, as of a PC, is successfully developed.

|

|

|

Fig. 1 Developed X-ray tubes (upper: low-power tube, lower: high-power tube) |

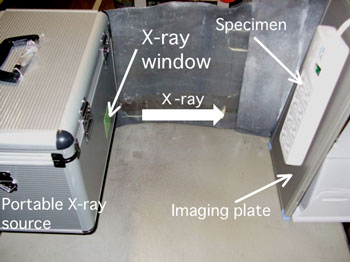

The developed X-ray tube with a high-voltage power source can be hand-carried in a case, and used to generate X-rays on site. Figure 2 shows the setup for X-ray transmission imaging using a low-power model of portable X-ray tube housed in a small case (37 cm × 13 cm × 35 cm) together with a power source. This X-ray source can be used in nondestructive inspection and medical diagnostics in the same way as a conventional hot-cathode X-ray source. The portable X-ray source is convenient to use because it eliminates warm-up time, a big issue for conventional hot-cathode X-ray tubes, and generate X-rays promptly whenever needed.

|

|

Fig. 2 Setup for X-ray transmission imaging using a portable X-ray source |

Furthermore, we can apply a large pulse current to the developed cold-cathode electron source and create an electron beam with a power of >10 kW using a high-power X-ray tube, and of >3 kW using a low-power X-ray tube. Using large-dose pulse X-rays, high-speed imaging of 1/1000 s is realized.

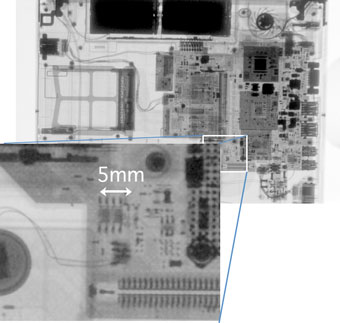

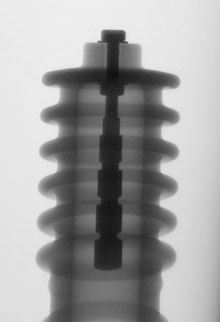

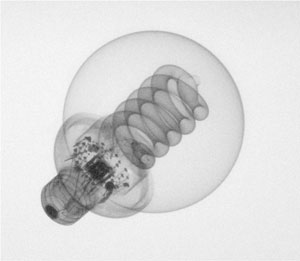

Figures 3-5 show X-ray transmission images taken using the X-ray source and an imaging plate. Exposure time of <1 s and input power of <15 mWh are used in taking the images. As a detector, we can also use a flat-panel type X-ray image sensor instead of an imaging plate.

Fig. 3 X-ray transmission image of a laptop computer. Low-power tube, exposure time 0.5 s. |

|

Fig. 4 X-ray transmission image of a metal rod electrode in an insulator (outside diameter ≈10 cm). High-power tube, exposure time 1/100 s. |

|

|

Fig. 5 X-ray transmission image of a compact fluorescent lamp. High-power tube, exposure time 1/1000 s.

|

An AA dry battery generally emits energy of >2.4 Wh, and more than 300 high-definition images can be obtained using a two-battery power source. With respect to the reliability of X-ray tubes, it is confirmed that no performance degradation is observed even after over 1 million shots at 15 mWh per shot. Furthermore, with the cold-cathode X-ray source using carbon nanostructures, we have confirmed the effectiveness of the technology in such usage as X-ray fluorescence spectrometry, in addition to the X-ray transmission imaging.

We intend to develop higher-energy and higher-output X-ray tubes using carbon nanostructures as the electron source to find applications for nondestructive inspection of larger structures. Studies are also pushing ahead for wider applications such as computer tomography (CT).