Kenji Tsuchihara (Senior Research Scientist), the Molecular Smart System Group (Leader: Masaru Yoshida), the Nanotechnology Research Institute (Director: Nobutsugu Minami) of the National Institute of Advanced Industrial Science and Technology (AIST) (President: Hiroyuki Yoshikawa) developed polymer films that change color instantaneously and reversibly in response to changes in the tension applied.

The polymer films were prepared on elastic substrates by spin-coating from solutions of substituted polyacetylenes developed. The color of these polymer films changed instantaneously and reversibly when the polymer films were stretched and contracted using a stretching machine. The change in color was repeatable, and it occurred with the application of a small force of manual stretching.

This technique is expected to be applied to a tension sensor, which visualizes stress easily and which has been difficult to realize.

Detail of the results will be exhibited as "Chromism of Substituted Polyacetylene Films" at the AIST Open Lab, held at AIST Tsukuba on October 20 and 21, 2008.

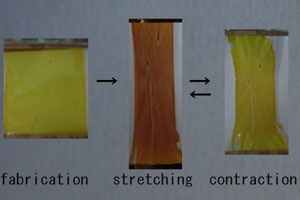

Figure 1 Chromism of Polymer 1 thin film before and after stretching |

|

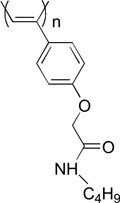

Chemical structure of Polymer 1

|

Polymeric materials that change color in response to various external stimuli such as heat, light, electric field, and magnetic field have been widely known and applied to various types of display devices and sensors. However, there exist a few polymeric materials that change color in response to mechanical stimuli. If such polymers can be put to practical use, mechanical stimuli can be visualized easily and inexpensively. For example, such polymers can be applied to a tension sensor, which will indicate dangerous spots evidently by detecting stresses acting on structures of buildings and then indicating them as a change in color.

It has been difficult to put polyacetylene, which is renowned as a conducting polymer, to practical use because it is not stable in air. However, substituted polyacetylenes into which substituents are introduced are suitable for practical applications because they are stable in air and allow the production of films from their solutions. AIST has been studying the syntheses of new substituted polyacetylenes and control of the optical properties of their films. The studies conducted have yielded the following results: observation of a reversible change in the color of polymers in response to external stimuli such as heat, control of the change in color in response to light, control of rapid chirality inversion, and amplification of chirality by forming higher order structures.

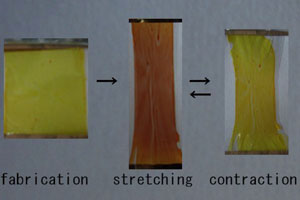

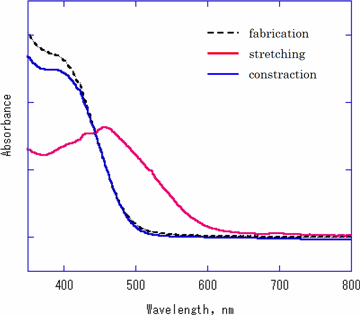

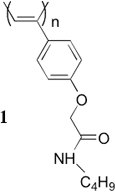

Polymerization of acetylene substituted with a substituted phenyl group (see Figure 1) using [Rh(norbornadiene)Cl]2 as a catalyst produces a polymer in which the main chain is in the cis conformation and has a helical structure (a repeating unit of this polymer is shown in chemical structurel 1). A film of this polymer was prepared by spin-coating from a chloroform solution of this polymer on a colorless elastic sheet. The color of the obtained film of the substituted polyacetylene was yellow at the time of formation. By stretching this film together with the sheet by using a stretching machine, the substituted polyacetylene molecules were oriented along the direction of stretching. Further stretching led to a color change in the film from yellow to red. Measurement of the ultraviolet-visible absorption spectrum indicated an increase in absorption from approximately 500 to 600 nm (Figure 2). Removal of the tension and contracting the film led to the return of the color of the film from red to yellow, and the absorption spectrum agreed with the spectrum before stretching. Thus, the change in color due to stretching and contracting was reversible.

|

|

|

|

Figure 2 A photograph and UV-visible spectra of Polymer 1 thin film before and afte stretching |

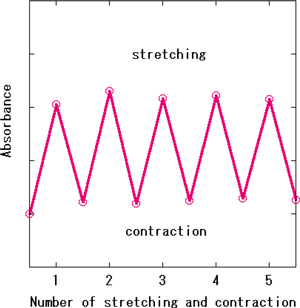

The color of the film changed instantaneously in response to quick manual stretching and contraction. The change in color was repeatable, that is, the change in color between yellow and red could be repeated by stretching and contraction repeatedly (Figure 3).

|

|

|

|

Figure 3 Absorbance at 540 nm of Polymer 1 thin film after repeating stretching and contraction |

In addition, it was found that the change in color depended not on the stretching ratio but on the tension applied.

Although the mechanism involved in this color change has not yet been revealed, it is speculated that this color change is a result of a change in the conjugated system of the main chain due to the change in length of the polymer molecules associated with the stretching and contraction of the film.

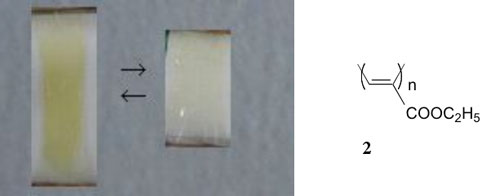

Films prepared from other substituted polyacetylenes also showed instantaneous reversible changes in color between colorless and yellow or between purple and blue. These changes in color were also repeatable (Figure 4).

|

|

Figure 4 Chromism of Polymer 2 thin film between colorless and yellow with stretching and contraction |

With the aim of realizing brighter and stable color changes and increasing color variations, we continue to carry out researches on a variety of polymers, in addition to an exploration of substrate films, change in color of free-standing polymer films, and blending of polymers with other polymers.