Update(MM/DD/YYYY):02/25/2008

Development of a National Standard-Level Voltage Generator Usable in Industry

- Desktop quantized voltage generator operable without liquid helium -

Points

-

A generator of a stable standard voltage of 10 V is strongly needed for industrial application.

-

High-yield ratio is realized by a series connection of two array chips, each of which contains about 300,000 Josephson devices.

-

High-quality product development is made possible through dramatically improved voltage measurement accuracy.

Summary

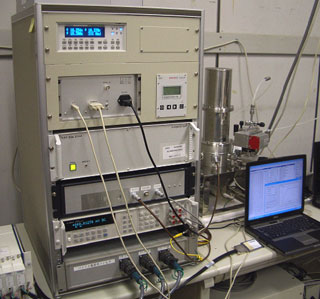

Yasuhiro Nakamura (Division Head) of the Electricity and Magnetism Division, the Metrology Institute of Japan (Director: Mitsuru Tanaka) and Akira Shoji (Group Leader) of the Superconducting Device Group, Nanoelectronics Research Institute (Director: Toshimi Wada) of the National Institute of Advanced Industrial Science and Technology (AIST) (President: Hiroyuki Yoshikawa) developed a desktop quantized voltage generator (Figure 1). This device generates the standard voltage of 10 V without liquid helium by using the commercial power supply for the first time in the world.

This technology was developed in order to provide the voltage standard necessary for the design, development, and quality management of products in such industries as the semiconductor, consumer electronics, automobile, and electricity industries. In particular, it can generate a quantized voltage of 10 V as the standard voltage that is unaffected by the changes in temperature, humidity, and pressure during simple operations.

We successfully generated quantized voltage of 10 V by connecting two array chips in series (called a “dual chip”), each of which contains about 300,000 niobium nitride Josephson devices (NbN/TiNx/NbN Josephson devices). The dual chip structure improved the yield ratio of the device, and paved the way for its practical applications.

The AIST-developed niobium nitride Josephson device is operable at a temperature (10 K) that is higher than the boiling point of liquid helium. So, it does not require liquid helium, which is indispensable to the conventional Josephson devices, and can generate the quantized voltage using a small cryocooler.

Because the newly-developed desktop quantized voltage generator has the same level of stability as the national standard, it is expected to replace the Zener-diode voltage generator that is currently widely used in the industry. Details of this technology were presented in the 6th DC and Low Frequency Electrical Standards Club on January 30, 2008 in AIST Tsukuba.

|

|

Fig. 1 Desktop quantized voltage generator

|

Social Background for Research

A highly stable voltage standard is vital for the design, development, and quality control of products in industries such as the semiconductor, consumer electronics, automobile, and electricity industries. At present, a voltage generator that employs Zener diodes is widespread for generating the standard voltage required in the industry. This equipment is compact and economical. However, its accuracy cannot be guaranteed unless it is calibrated using the national standard at least once a year because the voltage generated by the device fluctuates with time. The calibration costs at least several hundred thousand yens. Moreover, the generator cannot be used as a standard during the calibration. If Japanese companies have factories or plants in foreign countries, they have to ship their voltage generators to Japan for calibration and clear the customs formalities, thereby creating problems related to cost and inconvenience.

In order to solve these problems fundamentally, it is ideal that the industries use the quantized voltage generated by a Josephson device that has the same accuracy level as the national standard maintained by AIST. However, in order to generate a quantized voltage of 10 V required for the standard voltage, an array chip having a large number (up to several hundred thousand) of Josephson devices needs to be built.

Josephson devices with as few defects as possible need to be fabricated in order to let an array chip generate 10 V. However, their yield ratio is not so high at present. Josephson device array chips with an output of 10 V are available from foreign companies, but they are expensive. In addition, large equipment is required because the array chips are not operable unless they are cooled with liquid helium and their operation cost is large due to the consumption of liquid helium. These factors are obstacles to the introduction of these devices into the industry.

History of Research

In order to eliminate the constraint of requiring liquid helium for operation, in 2001, AIST started to develop the Josephson device (NbN/TiNx/NbN Josephson device) with niobium nitride electrodes that have a superconducting critical temperature exceeding 15 K. It successfully developed a NbN/TiNx/NbN Josephson device operable at about 10 K, a temperature that can be generated with a small G-M cryocooler.

In 2002, we fabricated an array chip comprising 30,000 NbN/TiNx/NbN Josephson devices. The chip generated a voltage of 1 V with a small cryocooler. (See Press Release of June 5, 2002.)

However, the industries wanted to have a device that could generate a voltage of 10 V with the same accuracy and stability as the primary standard instead of the device that generated a voltage of 1 V. For the generation of 10 V, almost 300,000 Josephson devices are required on a single silicon chip. We performed various experiments to develop an array chip that could generate a voltage of 10 V, and found that the current process technology cannot be used practically to integrate 300,000 defect-free Josephson devices on a silicon chip.

Details of Research

In order to overcome the above mentioned technological difficulty, i.e. one array chip containing defects cannot generate 10 V, we connected two array chips in series with a copper wire and generated a voltage of 10 V. The dual chip is a deceptively difficult idea. This developed technology, however, has paved the road for a higher yield ratio and lower production cost. Namely, it enabled to employ array chips that are used to be disposed due to the inability to generate a voltage of 10 V.

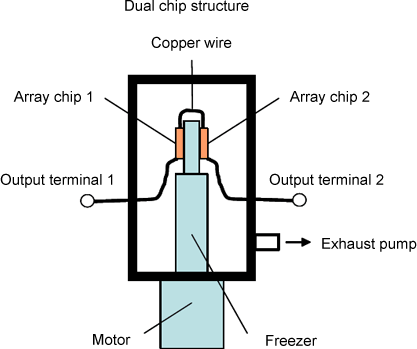

The voltage generated by the Zener-diode voltage generator that is widely used in the industry generally fluctuates plus or minus several µV a year. In contrast, the output of the newly-developed device does not fluctuate in principle because it utilizes the quantized voltage based on a physical phenomenon, i.e. the Josephson effect. In reality, the quantized voltage that is achieved by the Josephson effect and that we use as the national standard fluctuates less than plus or minus several nV. This means that a quantized voltage generator based on the Josephson effect is from several hundred to several thousand higher in stability than a Zener-diode voltage generator. Figure 2 shows the construction of a desktop quantized voltage generator with a 10 V output developed using the dual chip.

|

|

Fig. 2 Inside structure of a cryostat used for a desktop quantized voltage generator (A voltage of 10 V is generated between the output terminals 1 and 2.)

|

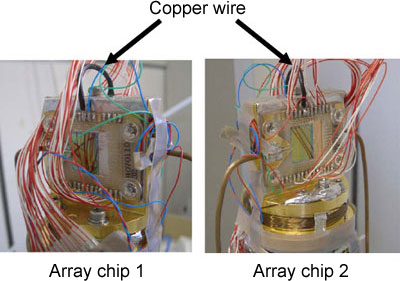

Figure 3 illustrates the position where the dual chip is installed, showing that the two array chips, each of which is 15 mm x 12 mm in dimension, are connected by a copper wire.

|

|

|

Fig. 3 Two Josephson junction arrays (a dual chip) mounted on a cryocooler

|

In Table 1, we show the comparison between the newly developed device and the national standard maintained by AIST.

|

Table 1 Comparison between the capability of the desktop quantized voltage generator and the national voltage standard of Japan.

|

|

Calibration result by means of the desktop quantized voltage generator |

9.99998766 V |

|

Calibration result by means of the national voltage standard |

9.99998765 V |

|

Difference |

0.00000001 V (10 nV) |

|

|

Values in Table 1 indicate the obtained data in cases where a commercially available voltage generator was calibrated by means of both instrument.

|

As shown in Table 1, the difference between the newly developed quantized voltage generator and the national standard is merely 10 nV (one billionth of 10 V); thus, we can conclude that it is by no means inferior in performance to the national standard.

If they replace the Zener-diode voltage generators in the industries in future, they will increase the accuracy of voltage measurement dramatically and enhance the development of higher-quality products.

Future Schedule

AIST will begin the charged distribution of the dual chip based on “Guidelines for Charged Distribution of Standard Substances and Developed Products for Measurement.” In future, we will evaluate the newly developed desktop quantized voltage generator in further detail, improve its accuracy, and examine the possibility of its application in industry and of its becoming the next-generation national standard.