Dr. Dang Fuquan, a researcher of Single-Molecule Bioanalysis Laboratory (SMBL), National Institute of Advanced Industrial Science and Technology (AIST), has developed a novel technology for preparing integrated plastic devices at low cost, in collaboration with Professor Osamu Tabata, Graduate School of Engineering, Kyoto University and Starlight Industries, Co., Ltd, Shiga Prefecture. Furthermore, the team has developed a highly-sensitive equipment to detect DNA in plastic devices, and demonstrated genetic diagnosis for diseases such as lung cancer in a short time using a trace amount of blood (3 µL). The time necessary for diagnosis including preparation of a DNA sample from of blood is as short as 16 min. Conventional genetic diagnosis is carried out in specialized facilities and requires blood as much as 2-3 mL and the time as long as 2-3 h. The newly developed technology makes it possible to perform simple, accurate, and rapid genetic diagnosis at the desk-side or bedside. Also, this technology is expected to be useful not only for genetic diagnosis of diseases but also for prediction of efficacy and side-effects of medicines based on the analysis of single nucleotide polymorphisms (SNPs). Furthermore, we expect that this technology will encourage the development of home medical care services, thereby protecting us from life-style dependent diseases and malignant tumors. Ultimately, this technology will contribute to extension of healthy life in the Japanese society of decreasing birthrate and aging population. The current achievements are going to be published in the April 1st issue of Analytical Chemistry, a journal published by American Chemical Society (ACS), USA and of Lab on Chip, a journal published by Royal Society of Chemistry (RSC), UK.

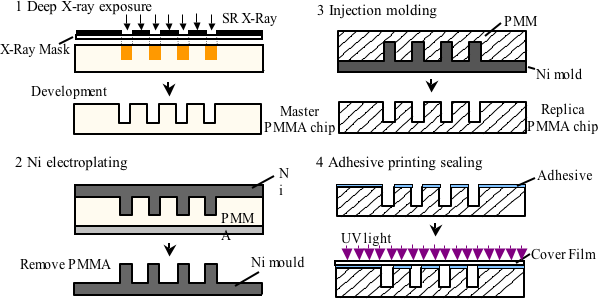

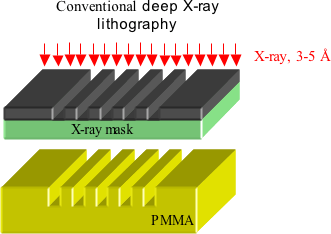

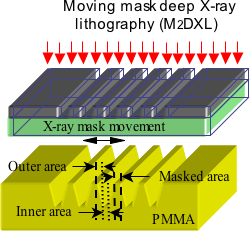

A total process for fabrication of plastic devices has been established (Step 1-4 in Fig. 1A). In this process, the method of preparing highly -integrated multi-channels on plastic devices, has been developed for the first time. The key of this method is to form at a slant (80~85º) on channel side walls using a newly-developed "moving-mask deep-angle X-ray lithography" (Step 1 in Fig.1 and more detail in Fig. 1C). The mold fabricated by moving mask technique allows mass production of multi-channel plastic devices through the injection molding technique (Step 3 in Fig. 1A). A mold with a slant on channel side walls is excellent for fabrication of multi-channel plastic devices without mechanical damage of each channel, because the slant structure makes it easy to separate a plastic chip from the mold. Indeed, using a conventional mold without a slant on channel side walls (Fig. 1B), each channel is often mechanically damaged during the separation of a plastic chip from the mold. This damage seriously limits the mass production of multi-channel plastic devices. In addition, a new technology has been developed for sealing plastic devices. The good-or-bad of sealing determines critically the performance of plastic devices (Step 4 in Fig.1). The key of the current sealing technique is to prepare a suitable amount of an adhesive on a sealing film to avoid leaking an extra adhesive into channels (Fig. 1D). In addition, dummy channels (lattice structures in Fig. 2A) are fabricated on plastic devices to collect an extra adhesive. A multi-channel plastic device thus fabricated (Fig. 2A and highlighted structures in Fig. 2B, C, D, and F) includes 10 micro-channels (50 µm width and 50 µm depth) in a width as small as 1 mm.. The density of micro-channels in this device is 3-10 times as high as that of conventional devices, while the cost of fabrication is 1/10 or smaller of the cost of conventional ones.

|

|

Fig. 1 A |

Fig. 1 B

|

|

Fig. 1 C

|

|

|

Fig. 1

|

Furthermore, a laser-based DNA detection system (Fig. 3) has been developed to analyze simultaneously 10 DNA samples moving through 10 micro-channels (Fig. 4) with high sensitivity and high speed.

Using highly-integrated multi-channel plastic devices, we have analyzed specific genes extracted from 3 µL blood (~1/10 of a drop of liquid). Fig. 5 shows the analysis of β-globulin genes as a demonstration of genetic diagnosis. Fig. 6 shows the analysis of SP genes for lung cancer diagnosis.

These results constitute a very important infrastructure for practical technology to bring the biochips to application for disease diagnosis. We expect that the current technology will be commercialized in within 3 to 5 years after finishing clinical tests in collaboration with medical institutions.

The development on of biochips is under intensive competition for application to diagnosis of diseases among academic, government and industrial sectors in Japan, United States and European countries. Nevertheless, many problems remain unsolved, such as complicated fabrication process, high cost of fabrication, and in difficulty in highly-reproducible fabrication of biochips.

SMBL-AIST has been in collaboration with Graduate School of Engineering, Kyoto University and Starlight Industries, Co., Ltd. aiming at the development of technology for low cost and highly-reproducible production of highly-integrated multi-channel plastic devices for clinical applications, such as genetic diagnosis. Additionally, the development was carried out in parallel with development of technologies for DNA detection equipment and pretreatment of blood and DNA samples to totally construct a genetic diagnosis system based on newly-developed plastic devices.

A top-notch technology for fabrication of highly-integrated multi-channel plastic devices has been developed as a basic technology for fabrication of biochips. The combination of current technology for low cost production of plastic devices with a system for highly-sensitive simultaneous detection of DNA loaded in 10-channels has been demonstrated in analyzing genes of cancer and other diseases in a time as short as 16 min using a blood sample as small as 3 µL (~1/10 of a drop of liquid).