Electronics and Manufacturing

Low-Reflectance, High-Durability Polarizing Sheet Applying Printing at the World's Narrowest Line Width

- HOKARI Ryohei, KURIHARA Kazuma

Advanced Manufacturing Research Institute

Update(MM/DD/YYYY):12/24/2020

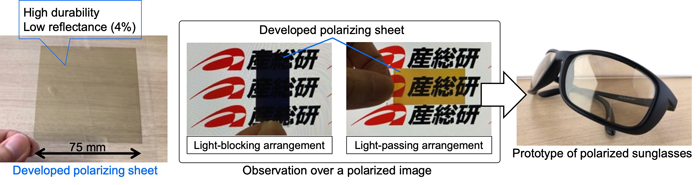

Low-reflectance, high-durability polarizing sheet patterned through ultra-high-resolution metal ink printing

A wire grid polarizing structure was created with metal ink to produce a low-reflectance wire grid polarizing sheet with polarization of 99% or more and reflectance of 5% or less, which is at most 1/10 the conventional reflectance of 51%.

|

| The developed low-reflectance, high-durability polarizing sheet |

Shortcomings of wire grid polarizers that combine high polarization and heat resistance

Polarizers are optical elements supporting polarization control technology that is needed in LCD panels and other products in a broad range of fields, including optical equipment such as LCD projectors, automotive equipment such as HUDs, manufacturing equipment such as lithography equipment, and polarized sunglasses. However, in environments where automotive equipment, LCD projectors, and the like are used, these elements in products must be highly durable to withstand heat, moisture, and light.

Although conventional wire grid polarizers offer a combination of high polarization, high transmittance, and thinness, they are also highly reflective, which has limited the scope of application to products such as LCD projectors.

99% polarization and 4% reflectance, applying the world's highest-resolution printing at a line width of 50 nm or less

The researchers combined nanoimprint and printing techniques to form the structure of the wire grid polarizer (with a high aspect ratio, and narrower than wavelengths of visible light) with metal ink. Suitable sintering enabled a world-first wire grid polarizing sheet with polarization of more than 99% and reflectance of less than 5%.

This technique has enabled reduced reflectance while retaining the advantages of conventional wire grid polarizers. Resistance to heat, moisture, light, and scratches make this technique promising not only in optical fields but also in eyewear and automotive industries, where application has been difficult.

Transmittance also sought in future research

With low reflectance from a wire grid polarizer achieved through the printing technique, the researchers will focus on both polarization and transmittance.

Contact

HOKARI Ryohei, Senior Researcher

KURIHARA Kazuma, Leader, Group

Surface Interaction Design Group, Advanced Manufacturing Research Institute

AIST Tsukuba East, 1-2-1 Namiki, Tsukuba, Ibaraki 305-8564 Japan

E-mail: webmaster-am-ri-ml*aist.go.jp (Please convert “*” to “@”)