Point

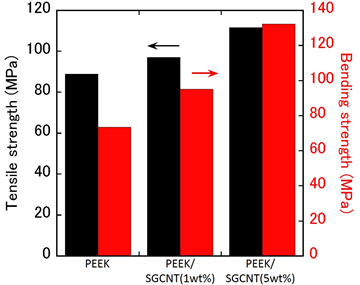

Polyetheretherketone (PEEK) is a high-performance plastic that serves as an alternative to aluminum and other materials in wide-ranging areas such as the automotive and aerospace industries. By adding single-wall carbon nanotubes synthesized by SG method (SGCNTs) to PEEK, a “PEEK/ SGCNT composite material” was developed. The composite material exhibits enhanced heat resistance, tensile strength, and bending strength beyond those of PEEK alone. This composite material is injection moldable.

|

|

|

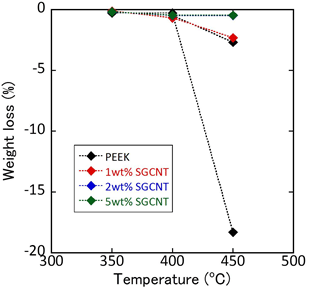

| Change in weight at a constant temperature |

|

Tensile and bending strength of PEEK and of PEEK/SGCNT composite material |

New Results

A new, ultra-high dispersion technology was developed that is suitable for mass production and can continuously defibrate SGCNTs and disperse them in PEEK to produce a PEEK/SGCNT composite material. This composite material is light-weight and injection moldable in the same way PEEK is, and it exhibits excellent heat resistance (stable for two hours at 450 °C).

Background

It has been known that SGCNT addition has an effect of heat resistance improvement on composite materials. In the past, carbon nanotube (CNT) composite materials were produced by dispersing CNTs in an organic solvent, dissolving a polymeric material in this solution, and then removing the organic solvent. However, there is no organic solvent that can dissolve PEEK, so production of a composite with SGCNTs has been difficult.

Future Developments

In the future, the researchers aim to realize more enhanced functions through the improvement of CNTs, increase the compatibility of PEEK with CNT to improve dispersibility, and establish a method for controlling CNT orientation at the time of molding, as well as other aims.

Contact

|

|

Seisuke Ata

Researcher

CNT Application Development Team, CNT-Application Research Center

AIST Tsukuba Central 5, 1-1-1 Higashi, Tsukuba, Ibaraki 305-8565 Japan

TEL: +81-29-861-4551

|