Researchers) YUASA Shinji, Research Center Director, YAKUSHIJI Kay, Team Leader, Spin Device Team, Research Center for Emerging Computing Technologies, TAKAGI Hideki, Principal Research Manager, Device Technology Research Institute

- Fabrication of single-crystal thin film for non-volatile memory MRAM on a 300 mm diameter silicon wafer

- Integration of single-crystal memory elements in silicon LSI using 3D integration technology

- Expected to contribute to next-generation MRAM and new superconducting qubits

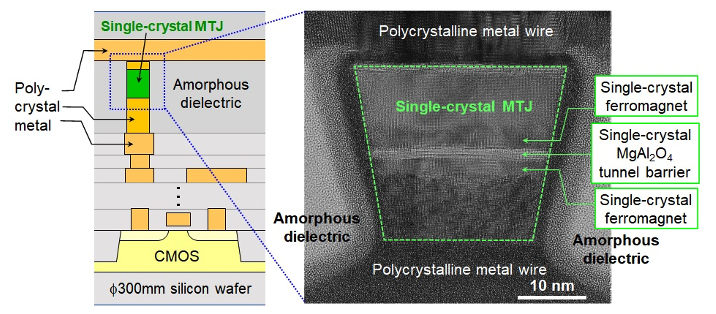

Electron microscopy image of single-crystal MTJ (right) integrated into non-volatile memory STT-MRAM (left)

Non-volatile memory MRAM have features such as high-speed read/write operations and excellent write endurance and are attracting attention from the viewpoint of information processing with low power consumption. Current main-stream MRAM products are current-driven MRAM (STT-MRAM). On the other hand, voltage-driven MRAM (VC-MRAM), which is in the research stage, consumes less power than STT-MRAM and therefore is expected as the next generation non-volatile memory. MRAM scaling for the 5 nm technology node and beyond and power consumption on a par with high-speed memory SRAM are the keys to realizing Society 5.0 and post-5G technology. Due to issues such as increasing performance variations and insufficient performance associated with ultra-high integration of MTJ elements, it is presently a challenge to achieve scalability and power efficiency in the MRAM technology.

Researchers in AIST developed fabrication process technology to integrate single-crystal memory elements for non-volatile memory MRAM in silicon LSI.

Non-volatile memory MRAM consists of recording bits comprised of magnetic tunnel junctions (MTJs), semiconductor transistors (CMOS) used as bit selector, and metal interconnects, etc. This memory is fabricated by directly depositing polycrystalline MTJs with magnesium oxide (MgO) tunnel barriers onto polycrystalline metal wires. However, MRAM is expected to reach its scaling limit with this conventional technology due to increasing performance variations and insufficient material properties of polycrystalline MTJ elements. Therefore, single-crystal MTJs with new materials and integration technology for the single-crystal MTJs are attracting attention as a solution for extend the scalability.

This research succeeded for the first time in fabricating a single-crystal MTJ thin film using the spinel oxide MgAl2O4 as a new material to replace MgO on a 300 mm diameter silicon wafer. Moreover, single-crystal MTJ elements were also successfully integrated into a silicon LSI for MRAM by 3D integration technology based on direct wafer bonding for the first time. This technology will contribute to the ultra-high integration of current mainstream non-volatile memory STT-MRAM, and also to VC-MRAM with higher performance and lower power consumption and superconducting qubits for quantum computers.