– Effective ceramic coatings with antiviral functions on surfaces such as metals, glass, and resins –

Researcher) AKEDO Jun, Director, Advanced Coating Technology Research Center, and Team Leader, Fine Powder Spray Coating Team, SOHMA Mitsugu, Principal Research Manager, Advanced Coating Technology Research Center, YAMADA Yoichi, Senior Assistant Professor, School of Pharmacy, Shujitsu University, UEDA Takeji, Visiting Scholar, School of Pharmacy, Shujitsu University

Researchers at AIST developed a novel technology for preparing antiviral coatings in collaboration with Shujitsu University. The coatings have immediate effects, and the effects last for a long time. The antiviral coatings can be impregnated with and slowly release surfactants that are effective against enveloped viruses in general, including the novel coronavirus (SARS-CoV-2).

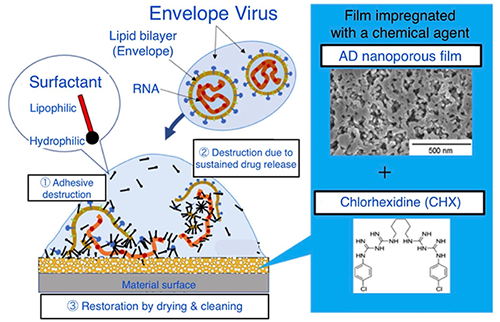

Principle of virus inactivation on a porous ceramic film carrying an antiviral agent

The active period of a virus adhered to a substance surface is highly dependent on temperature and humidity, and viruses can remain infectious for up to a week at low temperature and humidity. Thus, virus inactivation on solid surfaces remains an important theme1),2). Alcohol and surfactants can destroy enveloped viruses including the novel coronavirus, and this effect is highly versatile even when surface proteins on the virus varied.

Wiping with surfactant is effective, but it is difficult to do frequently for things that people touch in public places such as doorknobs, handrails, and straps. These things require virus inactivation in a short time as well as long-time persistence of antiviral effects. And they need to have various properties such as wear resistance, light resistance, and texture are important factors as daily materials. In these cases, we need a durable and tactilely pleasing coating that can gradually release an effective antiviral substance are required.

1) C. Xie, H. Zao, K. Li, Z. Zhang, X. Lu, H. Peng, D. Wang, J. Chen, X. Zhang, D. Wu, Y. Gu, J. Yuan, L. Zhang, and J. Lu, The evidence of indirect transmission of SARS-CoV-2 reported in Guangzhou, China. BMC Public Health, 20, 2020, 1202.

2) S. H. Bae, H. Shin, H-Y. Koo, S. W. Lee, J. M. Yang, and D. K. Yon, Asymptomatic transmission of SARS-CoV-2 on evacuation flight, Emerg. Infect. Dis., 26, 2020, 2705

AIST’s "Aerosol Deposition (AD) method" is a novel technology to fabricate a nanoporous alumina film with good durability and impregnating it with chlorhexidine (CHX), which is safe, highly antiviral, and widely used in disinfection. This coating exhibited remarkable antiviral effects with long-lasting virus inactivation effects even with surface cleaning and wear. This technology enables production of antiviral coatings that feel good at room temperature on surfaces of various materials such as stainless steel, glass, and resin. The coating has a slow-release effect, so use is expected in situations where frequent cleaning is a challenge.

Going forward, long-term durability will be further evaluated, and methods of refreshing the surface after coating and replenishing the CHX will also be investigated. CHX is one of the most widely used disinfectants, and application can be expected for a wide range of disinfection efforts in addition to viral countermeasures.

Cooperation with private companies will be promoted to conduct detailed examinations for each application with the aim of early practical application.