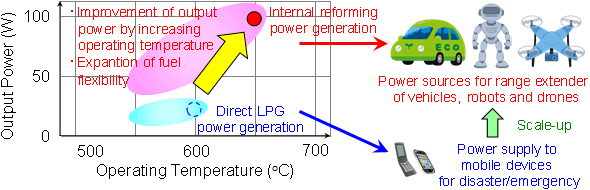

– Expectations for application to vehicles and robots by improvement of output power and durability –

A nano-structure-controlled electrode material and operation control technology have been developed for internal partial oxidation reforming of liquefied petroleum gas (LPG) and steam reforming of ethanol in solid oxide fuel cells (SOFCs). In collaboration with Atsumitec Co., Ltd., AIST has demonstrated a portable power generation system with compact size and high output power.

|

|

Improvement of output power by increasing operating temperature of SOFC |

The nano-structure-controlled electrode material has been developed for prevention of degradation due to carbon deposition during internal partial oxidation reforming of hydrocarbon fuels, such as butane, into hydrogen and carbon monoxide in SOFCs, and for promotion of an electrode reaction at temperatures above 650 °C. The operation control technology has also been developed for optimization of reforming conditions. As a result, a compact, high-output fuel cell module, that can produce output power with 3 times higher volumetric power density relative to conventional ones, has been successfully demonstrated. In addition, the operating conditions were optimized for power generation with internal steam reforming of liquid fuels, such as ethanol, with an eye to securing fuel flexibility for usability.

Stationary SOFC systems mainly using methane, such as residential combined heat and power (CHP) systems named as ENEFIRM, have been commercialized. AIST previously demonstrated a handy fuel cell system driven with LPG at temperatures of 400 to 600 °C for disaster/emergency power supply. In recent years, demands of range extenders for vehicles, robots, drones and so on are expected to increase rapidly. Therefore, portable SOFC systems that can generate power with liquid fuels, and are more compact with higher output power density are desired. Generally, the performance of SOFCs increases at high temperatures, but conventional electrodes easily deteriorate due to carbon deposition at high temperatures.

AIST will continuously investigate the internal reforming of other hydrocarbon and alcohol fuels to further expand fuel flexibility, and improve output power and durability of SOFC modules. It will also bridge the fuel cell module and the system technologies to companies for practical application to various purposes.