Enjoying Solvent-Free Artificial Nails

- YAMAMOTO Takahiro

Research Institute for Sustainable Chemistry

Update(MM/DD/YYYY):12/24/2020

Control of adhesion and peeling using light

The researcher has developed a technology that mixes a liquid crystal component with a paint material, and has shown that adhesion strength is significantly reduced by irradiation with near-ultraviolet light. The developed technology is expected to be applied to the peeling of artificial nails without using solvents.

|

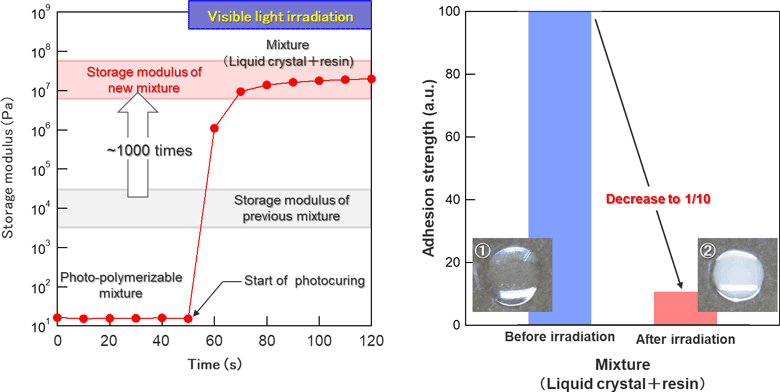

Comparison of developed mixture and previous mixtures

Left) Hardness (storage modulus); Right) Adhesion strength |

Artificial nails present health and safety issues

When artificial nails are used, a liquid photopolymerizable composition is applied to the nails, and this composition is polymerized and hardened by light in order to form a coating film. However, it is necessary to use organic solvents to remove these films, and this presents a health and safety issue. Peeling methods using acidic or alkaline aqueous solutions have been proposed, but have not yet been put into practical use. A technology for peeling of the films that does not use organic solvents has therefore been desired.

Colorless and transparent! And adhesion strength declines after 10 minutes of irradiation by light!

The developed material is a mixture of a liquid crystal and a resin mixed with a photopolymerizable substance. When this mixture is photo-cured by irradiation with visible light (wavelength: 405nm) for three minutes, its storage modulus, an index of the substance’s hardness, increases by approximately 1,000 times against previous mixtures. In addition, the researcher investigated liquid crystal components differing from azobenzenes, and developed a mixture that was colorless and transparent. It was shown that the adhesion strength of this mixture declined to 1/10th when irradiated by near-ultraviolet light (wavelength: 365nm) for 10 minutes.

Expected to be applied to paints, adhesives, etc.

The researcher intends to promote collaborations with materials manufacturers, towards the realization of practical application within a period of several years. The developed technology is expected to be applied not merely to artificial nails, but more widely to paints, adhesives and so on.

Contact

YAMAMOTO Takahiro

Senior Researcher

Smart Materials Group, Research Institute for Sustainable Chemistry

AIST Tsukuba Central 5, 1-1-1 Higashi, Tsukuba, Ibaraki 305-8565 Japan

E-mail: isc-web-ml*aist.go.jp (Please convert “*” to “@”)