- Control of a three-dimensional network of particles in a liquid crystal with light -

Masaru Yoshida (Leader) and Takahiro Yamamoto (Researcher), Smart Materials Group, the Nanosystem Research Institute (Director: Kiyoshi Yase) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Tamotsu Nomakuchi), have developed a gel material (a composite gel of polymer particles and a liquid crystal) that can repair damage to itself by light irradiation. The developed gel material can repair a small scratch on it in a short time by controlling its sol and gel states using light on the basis of photoisomerization of a photoresponsive material in the gel. This scratch-repairing process can be repeated. In addition, when transition to the sol state occurs due to large shear strain, the material quickly returns to the gel state by removing the applied strain.

The technology that can control the sol-gel transition of a material using light is expected to be a fundamental materials technology. Use of such materials in coatings that can be repaired with light will increase the durability and lifetime of products and can thereby contribute to resource savings and reduction in environmental loads.

The results of this research will be published online in Langmuir, a scientific journal of the American Chemical Society, on May 24, 2012 (JST). They will also be presented at the 61st Annual Meeting of the Society of Polymer Science, Japan, held at Pacifico Yokohama, Yokohama, from May 29 to 31, 2012.

|

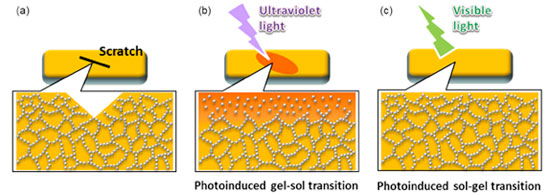

The repairing process of a scratch using photoinduced sol-gel transition

(a) Before light irradiation (with a scratch, gel state);

(b) after ultraviolet light irradiation (with no scratch, sol state);

(c) after visible light irradiation (with no scratch, gel state) |

Currently, gels as soft materials are used in a variety of applications, including foods, cosmetics, and industrial thickeners, and have the potential to be used in more. In recent years, self-healing materials using gels are being developed to increase the durability and lifetime of materials and equipment and thereby contribute to energy and resource savings. Requirements for self-repairing materials are: 1) they can repair themselves in a mild environment, such as at room temperature and in air; 2) they require no additive to repair damage; and 3) they can repair damage repeatedly. It is also important from a practical point of view that they can repair themselves in a short time. There is a need to develop gel materials with excellent properties that can be applied to self-repairing materials.

Focusing on the application of gels, AIST has developed a variety of gelling agents. In recent years, it has developed an organic electrolytic oligomer that can gelatinize a variety of solvents (AIST press release on May 25, 2007). In addition, as part of its effort to develop new gel materials, a photoresponsive material has been developed by incorporating azobenzene derivatives in a particle-liquid crystal composite system in which polymer particles are dispersed in a liquid crystal. By using cis-trans photoisomerization of azobenzene derivatives AIST has succeeded in controlling the aggregate state of particles and the optical properties of materials with light. In this research, by combining these materials technologies and focusing on a self-organized three-dimensional network of particles formed in a liquid crystal and the gel state appeared by the network, the researchers have developed a gel material whose sol-gel transition can be controlled by light and shear strain.

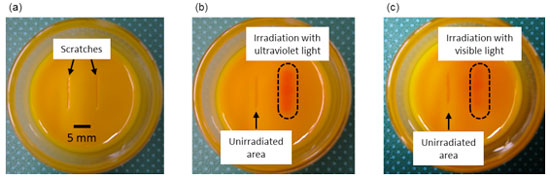

It has been known that particle-liquid crystal composites exhibit a gel state when the polymer particles form a three-dimensional network in the liquid crystal. In this research, the researchers have developed a photo-healable material by combining a composite with a photoresponsive material. A sol-gel transition of the developed material can be induced by controlling the three-dimensional network with light. A small amount of an azobenzene derivative is used as the photoresponsive material and the gel material repairs damage in the surface through the sol-gel transition induced by cis-trans photoisomerization of the azobenzene derivative (Fig. 1). The gel material in Fig. 1 was prepared by dispersing polymer particles (about 20 wt%) in a liquid crystal with a small amount of the azobenzene derivative (about 1 mol%). Small scratches (about 2 mm deep) were made on the surface of the gel material (Fig. 1a). When one of the scratches was irradiated by ultraviolet light (wavelength: 365 nm) focused by a lens for 10 s at a temperature of 32 °C (the temperature is slightly lower than the phase transition temperature of the liquid crystal, 35.5 °C, and the gel state of the material is kept), coloration due to the photoisomerization from the trans form to the cis form of the azobenzene derivative was observed in the irradiated area. At the same time, the phase structure of the liquid crystal changed from nematic to isotropic and the three-dimensional network of the particles was destroyed, causing the transition from the gel state to the sol state in the irradiated area. The transition to the sol state increased the fluidity of the material and the scratch was filled with the material in the sol state (Fig. 1b). When the azobenzene derivative was photoisomerized from the cis form to the trans form by visible light irradiation (wavelength: 435 nm) for about 10 s at the same temperature (32 °C) and the phase structure of the liquid crystal was changed to nematic, the three-dimensional network of the particles was restored, the material returned to the gel state, and the surface scratch was repaired (Fig. 1c). When the gel was left in a dark place for one night, the color of the irradiated area returned to the original color.

|

Figure 1 : Photo-healing of a surface scratch in the particle-liquid crystal composite gel

(a) Initial state;

(b) after ultraviolet light irradiation (irradiation time: ~10 s);

(c) after visible light irradiation (irradiation time: ~10 s) |

When the gel was left in a dark place for one night after the surface scratch was repaired, the color

of the irradiated area returned to the original color. |

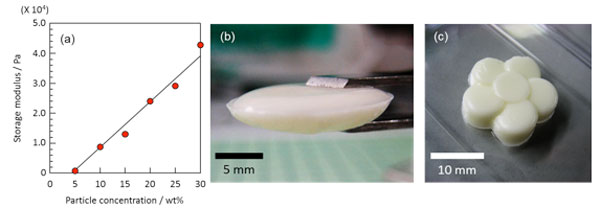

The relationship between the concentration of the added particles and the storage modulus was measured; the modulus is an index of hardness, a basic property of the particle-liquid crystal composite gel (Fig. 2a). Because the storage modulus of the gel material increases linearly with increasing concentration of the added particles, the hardness of the material can be tuned by the concentration. The increase in storage modulus is due to the fact that the strength of the three-dimensional network increased with increasing number of added particles. At present, it is possible to prepare a gel material with a storage modulus of more than 104 Pa. It has been confirmed that the material is sufficiently self-supporting to retain its shape and has good formability (Fig. 2b, c).

|

Figure 2 : (a) Relationship between the storage modulus of the particle-liquid crystal composite gel and the concentration

of the added particles; (b) self-supporting property (b) and formability (c) of the gel (concentration of the added particles: 30 wt%) |

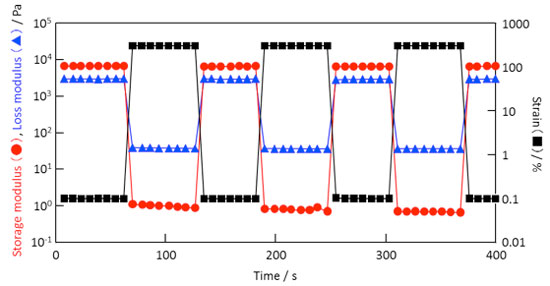

Generally, when large shear strain is applied to a gel material to destroy the three-dimensional network formed in the material, the material changes to the sol state and often does not return to the gel state, or otherwise takes a long time to return to the gel state. When a large shear strain was applied to the developed material, it changed to the sol state. The material, however, exhibited rapid thixotropy and returned to the gel state immediately after removal of the strain, (Fig. 3). With a small shear strain (■, 0.1%), the storage modulus (●) was larger than the loss modulus (▲) and the material was in the gel state (●>▲). When a large shear strain (300%) was applied to the material in the gel state, the loss modulus was larger than the storage modulus and the material changed to the sol state (▲>●). However, when the shear strain was reduced (0.1%) again, the material immediately returned to the gel state (●>▲). In this material, the particles aggregated strongly between nematic-phase domains of the liquid crystal and formed a three-dimensional network. This suggests that, after a large strain was applied, the three-dimensional network was not completely destroyed and the original three-dimensional network was restored as soon as the strain was removed, returning the material to the gel state. A similar phenomenon is known to occur in hydrogel materials whose solvent is water but it rarely occurs in gel materials which use organic solvents such as liquid crystals. This property is characteristic of the developed material.

|

|

Figure 3 : Rapid thixotropy of the particle-liquid crystal composite gel |

The developed gel material can repair damage using a sol-gel transition induced by light stimulation and exhibits rapid thixotropy. Self-healing coatings that increase the durability and life of a variety of products are expected through further development based on this gel material.

The developed gel material uses the azobenzene derivative responsive to ultraviolet light. To achieve repairing using light with different wavelengths, the researchers will investigate control of the sol-gel transition with visible and infrared light using photoresponsive materials with functional groups other than azobenzene. Aiming at the development of gels that can repair damage with light at lower temperatures and higher strength gels, they will also evaluate the effect of the amount of the added azobenzene derivative, the phase structure and phase transition temperature of the liquid crystal, and the size and materials of the particles. In the future, the researchers will pursue collaborative research with companies interested in these results to develop applications of gel materials, including coatings, in various industrial areas.