Researcher: TAJIMA Kazuki, Senior Researcher, Nanoparticle Functional Design Group, Nanomaterials Research Institute (present assignment: Adhesion Interface Group of the institute)

- Development of a light control device to control visible and near-infrared light that uses two types of functional nanoparticles as light control materials

- Large-area coating achieved by developing inks made of light control materials optimized for a slit coater, a type of industrial coating equipment

- Providing a safe and comfortable space in vehicles such as automobiles and airplanes, and in living environments such as homes

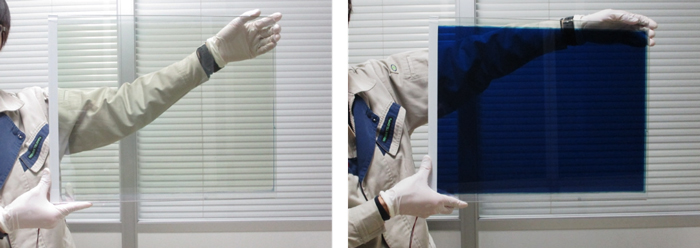

G2-size light control device in transparent state (left) and in light blocking state (right)

In vehicles such as automobiles, windows are used to view the outside from inside the vehicle. Glare from excess light coming in through vehicle windows and large amounts of heat entering or escaping through windows can spoil the comfort and safety of drivers and passengers. There is a growing need for light control windows that can control the light and heat coming in and out by changing the optical properties of the window in response to different conditions. The market for light control windows is expected to grow to US$ 8 billion in 2027, suggesting a high latent need for these windows. New solution-based materials and extremely efficient, low-cost manufacturing processes are required to achieve a market of this size.

The researcher, in collaboration with Toshiba Materials Co., Ltd., Toray Engineering Co., Ltd., and Hayashi Telempu Co., Ltd., has developed a process for manufacturing large-area light control devices that can block visible and near-infrared light. When a voltage is applied, electrochemical ionic conduction occurs in the developed light control device, making it possible to change the optical properties of the device based on the principle of electrochromism. AIST and others have produced inks by dispersing Prussian blue complex nanoparticles, which control visible light, and tungsten oxide nanoparticles, which control both visible and near-infrared light, in water. These inks have been optimized for use in a slit coater, a type of industrial coating equipment, making it possible to realize large-area film forming. The use of this device as a window efficiently reduces air-conditioning and lighting loads and achieves a safe space by changing its optical properties in response to different conditions.