– Elucidation of mechanism of conversion process provides clues for improving emission yield –

Researchers: FUNABASHI Ryoji, Leader, KAMADA Kenji, Chief Senior Researcher, and ABULIKEMU Aizitiaili, former AIST Postdoctoral Researcher, Integrated Functional Materials Group, Inorganic Functional Materials Research Institute

The researchers have realized a solid material that converts near-infrared light to yellow visible light by using the rapid drying cast method, in collaboration with Iwate University, The Nara Institute of Science and Technology, and Osaka University. This material consists of newly synthesized metal-complex molecules that absorb near-infrared light uniformly dispersed in a luminescent material on solidification.

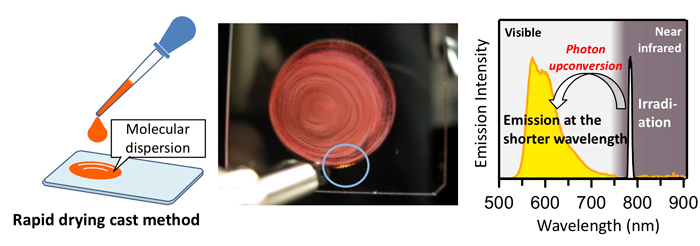

Solid material (center) fabricated by the rapid drying cast method (left), and spectra of irradiated light and emitted light (right)

Efficient conversion of the long wavelength components of sunlight to shorter wavelengths (light up-conversion: UC) can be expected to increase the conversion efficiency of solar cells. Recently, UC (TTA-UC) that makes use of triplet-triplet annihilation (TTA) between organic dye molecules is attracting attention as it works even with a light intensity on the level of sunlight. TTA-UC materials have two components, namely a sensitizer and an emitter. However, most TTA-UC materials so far have been solutions, which are not suitable for device applications, so solid TTA-UC materials that convert near-infrared light to visible light are demanded.

The researchers used the rapid drying cast method developed by AIST to prevent component separation and realized a solid TTA-UC material with a sensitizer uniformly dispersed in emitters, which are the main component of the material. The sensitizer is surrounded by the emitter molecules, so triplet-triplet energy transfer occurs efficiently. When irradiated with 790 nm near-infrared light, this material exhibits yellow (peak: 570 nm) luminescence with a quantum yield of approximately 0.5%, and operates with weaker light than conventional materials. It was also found that the fluorescence quantum yield of the emitter governs the overall efficiency.

The researchers intend to work to further increase the emission quantum yield, develop a method of creating a uniform coating film, and achieve applications in combination with devices, such as increasing the conversion efficiency of solar cells.