– Heat storage and cooling without melting inside electronics, machines, and structural components –

Researchers: FUJITA Asaya, Leader, NAKAYAMA Hiroyuki, Senior Researcher, and KINEMUCHI Yoshiaki, Senior Researcher, Entropics Materials Team, Magnetic Powder Metallurgy Research Center

The researchers have developed a technology that enables dense sintering of vanadium dioxide powder, which has excellent heat storage ability. This makes it possible to enhance mechanical strength without impairing heat storage density, and to process the sintered bodies by machining work.

|

|

Ice and vanadium dioxide powder (conventional material) (left), and developed vanadium dioxide sintered body (right) |

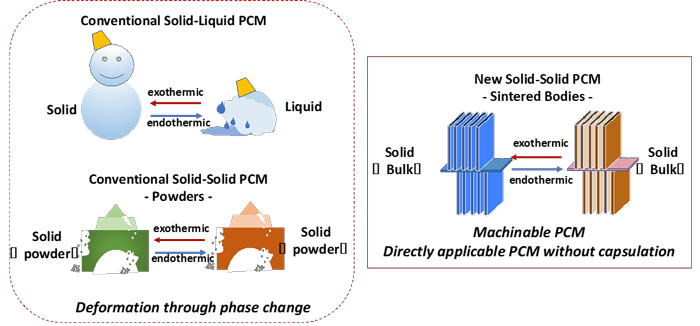

Expectations are increasing for development of heat storage technology that accumulates heat for use when needed. AIST previously investigated powder sintering and solidification technology for vanadium dioxide, which has high heat storage density, with the goal of industrial application. However, the resulting sintered bodies were brittle and unusable as components. This called for development of heat storage components that can be sintered and have high heat storage characteristics, mechanical strength, and workability.

The reactions that occur when sintering and solidifying vanadium oxide powder were examined in detail, and the researchers has devised a starting powder preparation method that significantly promotes sintering even without the use of a sintering aid other than vanadium oxides. This method enables easy production of bulk components with a size of φ50×5t (mm) using simple laboratory level equipment. The heat storage density value is comparable to that of ice and paraffin, and the compressive strength was increased to five times or more of that when using untreated powder. It was also confirmed that the heat storage operating temperature can be controlled from 5°C or less up to around 100°C.

The researchers intend to evaluate the thermal conductivity of the obtained components. They will also promote material design that enables control of characteristics such as temperature range and heat quantity in accordance with various uses.