A phosphorescent material was developed with around three-times the afterglow luminance and twice the emission time of conventional materials, even when used with LED lighting (460nm). A flexible phosphorescent film was produced using the Photo MOD (metal organic decomposition) method.

|

|

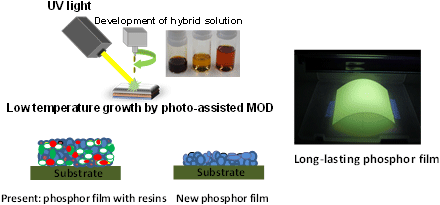

Figure 1. Comparison of a present phosphor film and the new phosphor film produced by the photo MOD method. |

The developed phosphorescent material was prepared using a new synthetic process, by precisely controlling the doping of metal ions with a chemical solution method using a metal organic compound. Furthermore, a hybrid solution was developed and a high-brightness phosphorescent film was produced on a PET substrate using the Photo MOD method. As this method does not require heat treatment, it is possible to produce a film with little degradation to the plastic substrate and/or the fluorescence property.

With the push to save energy, indoor lighting is being changed from fluorescent lighting to LED lighting. However, as LED lighting does not contain ultraviolet light, existing phosphorescent materials decrease in the afterglow luminance and the emission time. There was therefore a desire for the development of a high-intensity, long-lasting phosphorescent material, even in an LED lighting environment.

If a phosphorescent film coated with the developed phosphorescent material is used, in hazard evacuation guidance signs in skyscrapers, high-rise condominiums, etc., it could provide evacuation guidance for a long time. In addition, the Photo MOD method is applicable to the production of diverse functional ceramic films.