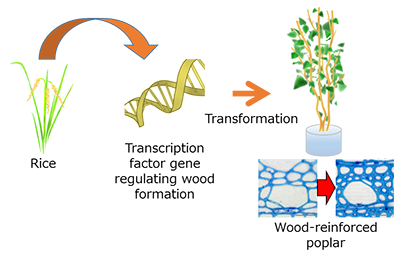

- Aiming for the efficient production of lignocellulose-derived fuels and materials and the development of high-strength wood -

Shingo Sakamoto (AIST Postdoctoral Researcher) and Nobutaka Mitsuda (Senior Researcher) of the Plant Gene Regulation Research Group, the Bioproduction Research Institute (BPRI; Director: Tomohiro Tamura), the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi) and others have developed the technology to significantly reinforce the wood of poplar by a rice gene, in collaboration with Naoki Takata (Senior Researcher) and Toru Taniguchi (Chief) of the Forest Bio-Research Laboratory, the Forest Bio-Research Center (Director: Kazumasa Yoshida), the Forestry and Forest Products Research Institute (FFPRI; President: Haruo Sawada).

In this technology, the gene of the rice OsSWN1 transcription factor, which regulates lignocellulose production, is introduced into poplar by gene engineering, improving the wood productivity by up to 40% and the wood strength by up to 60% without any growth retardation of the poplar. In the future, this technology is anticipated to contribute to the efficient production of lignocellulose-derived bioethanol and bioplastics, the development of high-strength wood, and a reduction in carbon dioxide emissions by the efficient production of wood-based next-generation fuel and materials.

This technology was developed as part of the research project of Strategic Basic Research Programs (Advanced Low Carbon Technology Research and Development Program: ALCA) of the Japan Science and Technology Agency (JST). Details of the results will be published online in the scientific journal, Scientific Reports, at 19:00 on January 27, 2016 (Japan Time).

|

|

The wood of poplar is reinforced by gene induction of the rice transcription factor that regulates lignocellulose production |

Plant-based fuels and materials have been developed to inhibit global warming and substitute for fossil fuels that will be depleted in the future. However, the currently available technologies to produce plant-based bioethanol and biomaterials are problematic, because these technologies are competitive with food production; therefore, the second-generation bioethanol and biomaterials that are made from the inedible material wood are anticipated to be developed and widely used. For this purpose, improvement of the wood productivity of plants is one of the important issues. In previous research, however, attempts to enhance wood productivity caused plant growth retardation; therefore, technology to improve wood productivity without inhibiting plant growth was needed.

AIST has been promoting research and development in the field of transcription factors in plants and has made world-leading achievements, such as the development of the unique technology called the CRES-T method to modify transcription factors and its application to the development of “polypetalous cyclamen” (AIST press release on March 16, 2010); the discovery of transcription factors that regulate cuticle formation (AIST press release on May 24, 2013); and the discovery of transcription factors, NST1 and NST3, that regulate lignocellulose production in Arabidopsis thaliana. FFPRI has achieved outstanding outcomes in developing technologies of tree breeding and gene engineering in trees. In this project, AIST and FFPRI successfully collaborated on research and development to improve the wood productivity and processability by use of a transcription factor.

This research was conducted as part of the research project, “Building new wood in plant with no wood (started in 2011)” (research representative: Nobutaka Mitsuda), categorized in “Biotechnology” (general manager: Akihiko Kondo) of JST Strategic Basic Research Programs (Advanced Low Carbon Technology Research and Development Program: ALCA).

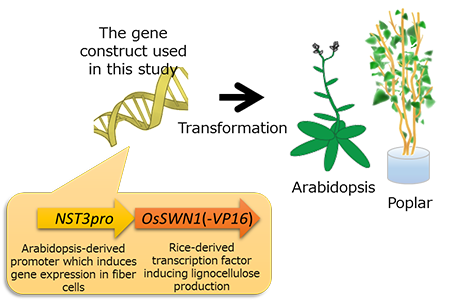

A key point of this technology is the induced expression of the rice OsSWN1 transcription factor gene mainly in fiber cells in poplar, based on the following findings: (1) this gene is an orthologue of genes of A. thaliana NST1 and NST3 transcription factors that regulate lignocellulose productivity; and (2) the rice OsSWN1 transcription factor is a very strong activator of lignocellulose productivity. To express the rice OsSWN1 gene in fiber cells, the A. thaliana NST3 promoter (the region that determines the expression of the NST3 gene) was used, because the A. thaliana NST3 gene is mainly expressed in fiber cells and its promoter can induce the expression of other genes in these cells. A DNA construct containing the rice OsSWN1 gene and the A. thaliana NST3 promoter (Fig. 1) was made and used to transform A. thaliana. As a result, lignocellulose production was observed in sites in which such production usually did not occur, suggesting an excessive accumulation of lignocellulose. On the other hand, the control experiment with a construct containing the A. thaliana NST3 gene instead of the rice OsSWN1 gene hardly demonstrated any such accumulation.

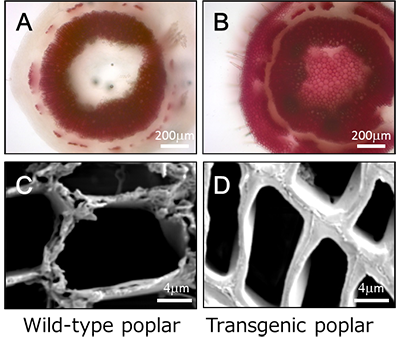

The researchers next added a domain (VP16) to the rice OsSWN1 gene in the DNA construct to enhance the activity of the transcription factor. When this modified construct was used to transform young poplar seedlings of height of up to 15 cm, lignocellulose production was observed in sites in which such production usually did not occur, which was similar to the case of A. thaliana (Fig. 2B). In addition, the fiber cells (in which lignocellulose production usually occurred) in the transgenic poplar showed thicker accumulation of lignocellulose (Fig. 2D).

|

Figure 1: A DNA construct that was used in this research

The construct was made by fusion of the A. thaliana gene promoter that induces gene expression in fiber cells (NST3pro) and

the rice transcription factor gene that induces lignocellulose production (OsSWN1(-VP16)). |

|

Figure 2: Cross-section of stem (A and B) and scanning electron microscopic image of fiber cells (C and D)

in wild-type (left) and transgenic (right) poplar.

In panels A and B, lignin in woody tissue is stained in red. In the transgenic poplar (B), sites that are not usually lignified

show woody tissue production (namely, cortical layers and pith of the stem).

A greater accumulation of lignocellulose is observed in fiber cells in the transgenic poplar (D) than in wild-type poplar (C). |

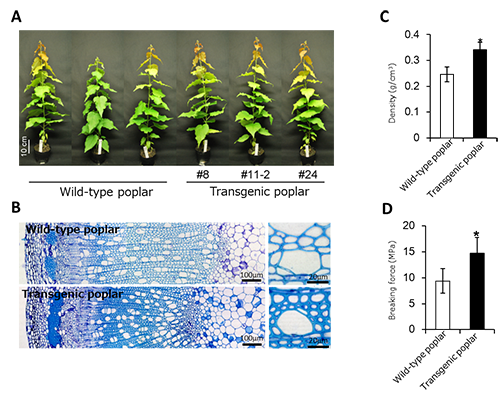

Further investigation was performed after these poplar trees were grown to a height of up to 60 cm. Thus, the gene engineering did not cause growth retardation but resulted in an excessive accumulation of lignocellulose. In the transgenic poplar, the average density of the stem and the average physical strength against rupture were improved by up to 40% and 60%, respectively, compared to those of wild-type poplar (Fig. 3).

|

Figure 3: Growth (A), woody tissue (B), stem density (C), and physical strength against rupture (D) of wild-type poplar and transgenic poplar.

After the transgenic plants grew to a height of up to 60 cm, no growth retardation was observed (A) but reinforcement of woody tissue was maintained (B).

Among five strains of transgenic poplar, the average density of the stem was increased by up to 40% (C) and the average physical strength against rupture was improved by up to 60% (D).

An asterisk (*) in panels C and D indicates that the value difference is statistically significant between wild-type poplar and transgenic poplar. |

The researchers aim to increase wood-biomass production by combining this technology with others that improve biomass production, such as enhancement of photosynthetic activity, and at the goal of improving wood processability and extracting a larger amount of sugar, for example, by modifying lignin in reinforced woody tissue. In addition, the researchers will consider the application of this technology to other trees, such as eucalyptus or acacia. The ultimate goal by around 2030 is to reduce carbon dioxide emissions by 40 million tons per year by improving the efficiency of wood-based bioethanol production by 50% and by applying this technology to 20% of the plants cultured for wood-biomass production worldwide.