Update(MM/DD/YYYY):03/02/2005

Energy Conversion Efficiency of World Top Level with Organic Thin-Film Solar Cell

- A Great Leap Forward to Implementation of Plastic Film Solar Cell-

Key Points

-

Organic thin-film solar cell based on organic semiconductor is a solid-state solar cell working in the same principle as silicon solar cell, but its energy conversion efficiency is rather poor.

-

The efficiency of light utilization has been improved by preparing p-i-n junction organic thin-film solar cell with nano-structured layer (i-layer) introduced to organic p-n junction interface to form multiple nano-p-n junctions, to achieve 4 % efficiency, a world top level among the organic thin-film solar cells.

-

Implementation of plastic film solar cells characterized by lightweight and flexibility will be accelerated.

Synopsis

The Photonic Research Institute (PRI) of the National Institute of Advanced Industrial Science and Technology (AIST), an independent administrative institution, has found that introducing a nano-structured layer (i-layer) where organic semiconductor forms a 3-dimensional p-n junction at the molecular level into p-n junction interface of organic thin-film solar cell based on organic semiconductor to construct a p-i-n junction expands the photovoltaic conversion layer to enhance the efficiency of light utilization. With the p-i-n type organic thin-film solar cell, an energy conversion efficiency, 4 %, a world top level, has been achieved under the condition of simulated solar radiation of AM1.5G. It is expected that this feat will accelerate the implementation of plastic film solar cell characterized by lightweight and flexibility.

The organic thin-film solar cell, of which practical use as low cost, flexible solar cells is pursued for, is a solid-state solar cell based on the same principle as the widely used silicon solar cell, and has a long history of R&D longer than 30 years. However, its energy conversion efficiency has been rather poor, and upgrading the energy conversion efficiency provides is the most significant hurdle for enjoying the practical application.

The solid-state solar cells, either organic or inorganic, are based on the photovoltaic effect of p-n junction. As the photovoltaic conversion layer of p-n junction in organic semiconductor is as thin as a few nanometers, the efficiency of light utilization is so poor with the conventional simple layered solar cell that adequate photocurrent could not be derived. For this reason, upgrading of light utilization efficiency by expanding the photovoltaic conversion layer has been regarded as the key factor for improving the energy conversion efficiency of organic thin-film solar cells.

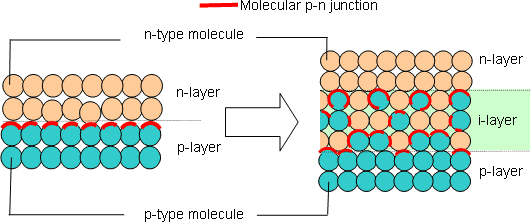

The PRI-AIST has found that introducing a nano-structured layer (i-layer) where organic semiconductor forms a 3-dimensional p-n junction at the molecular level into p-n junction interface of organic thin-film solar cell to construct multiple p-n junctions expands the photovoltaic conversion layer.

For n- and p-type organic semiconductors, fullerene (C60) and zinc phthalocyanine (ZnPc), respectively, are used, and the preparation of p-i-n junction organic thin-film solar cell by introducing a nano-structured layer with mixed ZnPc and C60 (ZnPc: C60 = i-layer) into p-n junction interface composed of ZnPc and C60, has boosted the energy conversion efficiency to about 4 %. This value is at the top level among the organic thin-film solar cells as evaluated under the simulated solar radiation of AM1.5G. While the newly developed organic thin-film solar cells have a lot of light input left still untapped owing to the thinness of photovoltaic layer, it is expected that further enhancement of light utilization efficiency by building tandem structures will make it possible to improve the energy conversion efficiency substantially. Getting the perspective for upgrading the energy conversion efficiency of organic thin-film solar cells in this way, is expected to accelerate the realization of plastic film solar cells markedly.

|

|

Photo. Currently predominant silicon solar cell (left) and plastic film solar cell (right)

|

Background

The solar photovoltaic power generation utilizing clean and inexhaustible solar energy is expected to be the major domestic energy source in future in view of preventing global warming. The power generation cost with prevailing silicon solar cells is currently about 3 times as high as that of household power price, and about 6 times that of industrial power price. For spreading the photovoltaic power generation, it is essential to reduce the cost of solar cells, and it has been argued what type of solar cells are to be put to practical use for this purpose. One of the most promising candidates is organic thin-film solar cell, which can be produced at a reduced cost by printing on flexible plastic substrate. R&D works on the solar cells of this category have been actively pursued in the US and European countries, since the beginning of the 21st century.

There are two types of semiconductors depending upon the electric charge of carriers: p-type with current carried by positive holes (positive charge), and n-type by conducting electrons (negative charge). Among organic materials, there are a number of semiconductors of either type. The concept of using organic semiconductors in place of silicon or other inorganic semiconductors to develop low cost film solar cells has come up with since earlier, and R&D efforts have been made already since the latter half of 1970s. However, its energy conversion efficiency has hardly exceeded 1 % or so, holding up the progress, and a breakthrough enhancement of energy conversion efficiency has been longed for.

Meanwhile, R&D of organic electroluminescent (EL) device, of similar structure as organic thin-film solar cell has been started from the latter half of 1980s, a little behind the latter. Nevertheless, the organic EL device has already been put to practical application, and a lot of findings have been accumulated on the organic semiconductor devices throughout the process. In particular, it has been noted that fullerene (C60) spotlighted because of soccer ball-like molecule behaves as n-type organic semiconductor of excellent performance, meeting the requirements for reviving the organic thin-film solar cells.

However, the combination of n-type organic semiconductor, fullerene, with typical p-type organic semiconductor, phthalocyanine, to construct an organic version of p-n heterojunction solar cells did not result in sizable improvement of energy conversion efficiency. This may be attributed to the inadequate thickness of photovoltaic conversion layer formed at the p-n junction interface of the organic semiconductor, a few molecules thick or a few nanometers, 3 orders of magnitude thinner that that of silicon solar cells. Most of solar radiation passes through the conversion layer, and only a very small part of incident light energy is used for the photovoltaic conversion.

History of R&D Work

The present research work has been carried out by the support from the New Energy and Industrial Technology Development Organization (NEDO), another independent administrative organization, under contract programs, R&D for Innovative Photovoltaic (PV) Technology in R&Ds for PV Power Generation System Technology, "Investigation of Organic Thin Solid Film Solar Cells" (fiscal years 2002~04).

Details of R&D Work

The PRI-AIST has designed the device for upgrading the conversion efficiency by replacing a thin, 2-dimensional photovoltaic conversion layer at the p-n junction interface with a thick 3-dimensional structure. Consequently, a nano-structured layer (ZnPc:C

60) is formed at the p-n junction interface composed of p-type organic semiconductor, phthalocyanine derivative (ZnPc), and n-type organic semiconductor, fullerene (C

60), to provide multiple nano-p-n-junctions at molecular level, increasing the effective thickness of photovoltaic conversion layer and improving the energy conversion efficiency (Fig. 1).

|

Fig. 1. Augmentation of molecular p-n junction interface by introducing a nano-structured layer (i-layer) to the p-n junction |

The ZnPc: C60 layer consisting of p-type and n-type molecules contains nearly same number of electrons and positive holes, to be regarded as an intrinsic semiconductor layer (i-layer) macorscopically, and the newly developed solar cell may be considered as an organic version of p-i-n junction type solar cell. The technique of augmenting the thickness of photovoltaic conversion layer by forming p-i-n junction with intrinsic semiconductor layer (i-layer) added to the p-n junction interface has been often applied to silicon or other inorganic solar cells. The details of this technique will be described below.

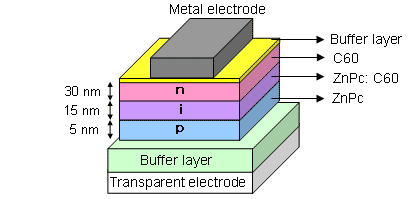

(1) A p-i-n junction type organic thin-film solar cell is prepared by vacuum deposition process. The i-layer is formed by co-deposition with volume ratio controlled at [ZnPc]:[C60] = 1:1. Thickness of three layers of organic semiconductor is 5 nm for p-layer, 15 nm for i-layer and 30 nm for n-layer, totaling 50 nm. An organic buffer layer is inserted between each electrode and organic semiconductor interface for establishing good contact (Fig. 2).

|

Fig. 2 Structure of p-i-n junction type organic thin-film solar cell |

(2) The newly developed p-i-n junction type organic thin-film solar cell proved to have energy conversion efficiency as high as about 4 % under simulated solar radiation of AM1.5G. This is at the world top level among the organic thin-film solar cells

(3) The current-voltage characteristics of the p-i-n type organic thin-film solar cell can be analyzed on the basis of ideal equivalent circuit of a generalized solar cell. Consequently, its diode factor is found to be 1.6 comparable to that of silicon diode, despite extremely thin organic semiconductor layer, as thin as 50 nm. If the diode factor is closer to 1, the p-n junction has performance closer to the ideal one, favorable in respect to energy conversion efficiency. Based on these results, it may be concluded that the newly developed p-i-n junction type organic thin-film solar cell can create good p-n junction, and has adequate potential for realizing higher efficiency organic thin-film solar cell.

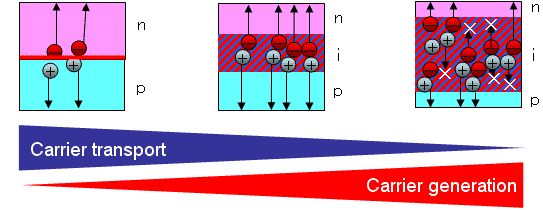

(4) On assessing the solar cell characteristics while changing the thickness of i-layer continuously, it has been found that the greater the i-layer thickness is, the higher the efficiency of light utilization becomes, with carrier generation augmented, though the carrier transport is reduced contrarily, presenting a thickness of i-layer for a maximum energy conversion efficiency. This may be attributed to the growth of probability for carrier recombination because of co-existing p- and n-type molecules within the i-layer (Fig. 3). At present, the aggregation of p- and n-type molecules within the i-layer is not subjected to any control, with an optimal efficiency at the i-layer thickness 15 nm. If the nano-structure were controlled so that the recombination of carriers is suppressed on increasing the i-layer thickness, it would be possible to upgrade the energy conversion efficiency further.

|

Fig. 3 Relationship of carrier transport and carrier generation to the thickness of i-layer |