- The simulation program facilitates cost reductions in the development of plasma process technologies -

Materials processing technologies using plasma have progressed rapidly in recent years, including technologies used in the manufacture of semiconductors, plasma displays, solar panels, and thin-film sensors. As a result, there has been significant demand for the development of an integrated computer simulation system of plasma and gas for application in a wide range of fields, from plasma materials science to semiconductor and vacuum device manufacturing. However, numerical analysis is difficult to perform in simple physical and mathematical models because (1) the electrons, ions, and neutral radicals associated with the process cause various physical and chemical reactions in the gas phase and on the vessel or substrate surface, which differ significantly in terms of time and space and (2) there is significant non-linearity in unequilibrated plasma. Therefore, there is considerable demand for the development of a computer program that can overcome these issues and cope with gas, solid, and plasma interactions in the entire system.

In collaboration with PEGASUS Software Incorporated, the Durable Coating and Surface Modification Group of the Institute for Structural and Engineering Materials (ISEM) at the National Institute of Advanced Industrial Science and Technology (AIST) has developed an integrated computer program for the analysis of plasma processes and rarefied gases. The program enables computer analysis of the interactions between the vacuum chamber inner wall or test sample surface and the plasma, in terms of gas flow, plasma behavior, sputter etching, and other factors.

The computer program involves the preparation of numerous module groups and the selection or combination of these modules to meet the process objectives, so it can be easily expanded for use with a wide range of applied technologies. The program can be used to analyze the processes in the entire system, so it is expected to contribute to improved efficiency in equipment design and improvement, as well as significantly lower experimental and prototype costs.

The program can be used for process analysis in a wide range of equipment, including that used in plasma enhanced chemical vapor deposition (PECVD), etching, plasma display panels, magnetron sputtering, ion injection devices, and various vacuum equipment.

The plasma and gas process simulation program will be launched under the name PEGASUS, from December. PEGASUS Software will also provide consultancy services on appropriate module combinations for use with different equipment.

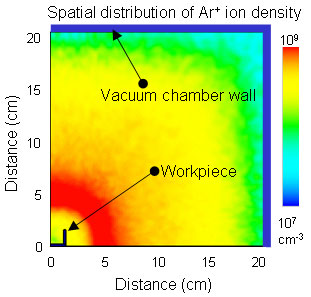

Example of the simulated results by PEGASUS:

|

Spatial distribution of plasma density generated when a positive pulsed voltage (maximum voltage: 2 kV, pulse length: 5 μs) was applied to the workpiece under investigation (H shape in cross section). The results show that a high-density region of plasma was generated around the workpiece. |