- Catalyst has potential for application in measures against nosocomial bacteria and decontamination of water with bacterial levels of 5-30 ppm -

The mesoporous ceramics research group at the Ceramics Research Institute of the National Institute of Advanced Industrial Science and Technology (AIST) has developed a novel ceramic catalyst (patent pending) that can kill Escherichia coli and MRSA. The ceramic catalyst may be useful for water decontamination, as it can be used to treat water containing extremely low bacterial levels of the order of 5–30 ppm and can also break down bleach and toxic organic compounds. The catalyst can be used in baths and pools, to prevent nosocomial infections, and to sterilize and clean medical devices and clothing, as it is safe and harmless. It may also dramatically reduce the use of chlorine-based agents. The catalyst is being commercialized by Health Chemical Co., Ltd., as a bath cleaner.

The new material consists of a ceramic catalyst containing a titanium dioxide photocatalyst coated in apatite. It can adsorb and break down bacteria and organic compounds. A novel design by the research group head Tooru Nonami enabled an effective reaction even using the light emitted from household fluorescent lighting. Moreover, the photocatalyst can kill E. coli and MRSA at these low levels of light once the apatite has adsorbed the bacteria.

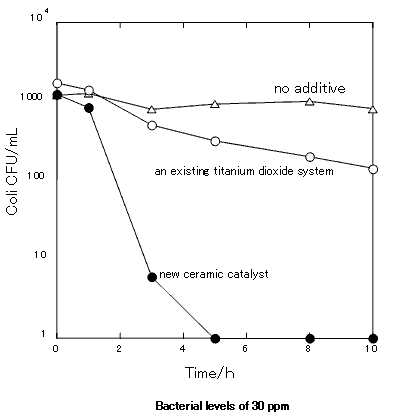

The figure shows the results from experiments using E. coli. With an existing titanium dioxide system, a solution of 1000 CFU/mL still contained around 600 CFU/mL after 5 hours’ treatment. However, with the new material, a solution of around 30 ppm (3 g per 100 L) contained under 10 CFU/mL after 3 hours’ treatment and 0 CFU/mL after 5 hours. These results demonstrate that the new material is extremely effective.

Chlorine-based agents are normally used to clean bathwater, but they cause the generation of trihalomethanes and various other environmental problems related to safety . The new material could dramatically reduce the use of chlorine-based agents and enable E. coli disinfection, as well as break down substances such as organic matter in bathwater and slippery substances on bathtubs. As the research was a partly collaborative project, Health Chemical Co., Ltd., is commercializing the product as a bath cleaner and will present the product at the International Hotel and Restaurant Show HOTERES JAPAN 2002 that opens on 12 March 2002 at Tokyo Big Site. AIST has already filed for a number of patents on the ceramic catalyst.

The ceramic catalyst has potential for use as a denture-cleansing agent and in measures against nosocomial infections. It could also be used to sterilize and clean clothing, electronics parts, machine parts, and food. In addition, the catalyst exhibits superior organic compound breakdown and bleaching capabilities. Systems containing titanium dioxide alone have almost no bleaching effect on paper stained with blood components or tobacco tar, but the ceramic catalyst produces exceptional results with bleaching in around 5 minutes. The research group has also confirmed that the catalyst can completely eliminate calcium deposits, such as dental calculi (tartar), and it expects to develop other applications in the future. AIST plans to establish ties with companies that wish to obtain more information or conclude a technology transfer agreement.

The new ceramic catalyst is expected to be available for applications in the near future, as low-cost production and simple manufacturing methods are possible.