- Realizes application in highly elastic pressure sensor sheets that fit the body –

Manabu Yoshida (Leader), Sei Uemura (Senior Researcher) and Taiki Nobeshima (AIST Postdoctoral Researcher) of the Printed Electronics Device Team, the Flexible Electronics Research Center (Director: Toshihide Kamata), the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi), have developed a highly elastic spring-shaped conductive wire by forming conductive fibers into a spring shape to achieve highly elastic devices.

The researchers also used highly elastic oriented short-fiber electrodes made by imparting a high orientation property to conductive short fibers and patterning them. Capacitive pressure sensors were then made that use changes in capacitance. A matrix of many such pressure sensors was formed using the highly elastic spring-shaped conductive wires and a highly elastic pressure sensor sheet was fabricated. The pressure sensor matrix sheet is highly durable, resistant to breakage even when stretched and folded, and flexible. Therefore, the sensor sheet can fit the human body and other surfaces. The newly developed highly elastic conductive wire is believed to have potential applications in a variety of highly elastic sensor sheets. It is expected to contribute to the realization of comfortable and reliable wearable devices and medical and healthcare devices such as heart rate and blood flow sensors.

Details of the technology will be presented at the 7th International Exhibition and Conference for the Printed Electronics Industry (LOPEC 2015) to be held on March 4-5, 2015 in Munich, Germany and at the 62nd JSAP Spring Meeting to be held on March 11-14, 2015 at Shonan Campus of Tokai University (Hiratsuka, Kanagawa Pref.).

|

|

Stretched electrodes using the newly developed highly elastic and durable conductive wires |

Devices that can be worn on the human body have come under increasing attention recently. Such wearable devices are expected to be utilized particularly in the medical and healthcare fields. For example, researchers are studying devices for everyday health management, such as long-term heart rate monitoring and body motion sensing. Because wearable devices have to fit the curved surface of the human body and other surfaces, they are required to be highly elastic and durable enough to tolerate repeated stretching and bending. A wide variety of elastic wires have been developed to achieve highly elastic wearable devices, but there are considerable changes in resistance value during stretching (i.e., the resistance value varies by 100 times or more when the stretch rate is 200 %). And when such wires were used as signal wires of sensors and the like, they have only been able to stretch about 20-30 %. Moreover, flat cables used as signal wires for conventional sensor sheets have not been very durable to bending, lasting only for about 10,000 repetitions of a bending radius of 10 mm (the cable breaks when folded).

Therefore, to realize wearable devices that are both comfortable and highly reliable, it is necessary to develop a highly elastic and durable conductive wire as well as sensor sheets using such wires.

AIST has been conducting the research and development of large-area flexible electronic devices, as well as electronic devices that can be freely shaped. The aim has been to develop technology with a focus on printing-based manufacturing processes. Technologies developed so far include all-printed memory arrays, RF tags, transpiration volume sensors, and large-area pressure sensors. A particular effort has recently gone into the development of large-area flexible devices that would fit the human body and other curved surfaces.

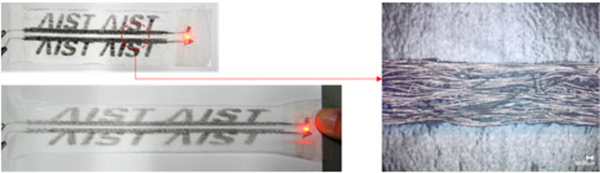

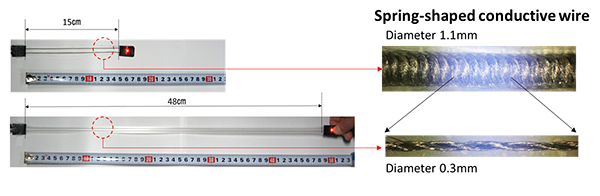

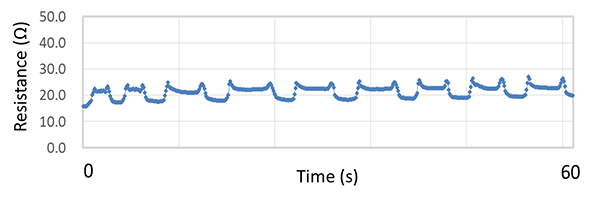

Conductive fibers were formed into a spring shape on a highly elastic resin sheet to develop a highly elastic conductive wire. This conductive wire has very stable electrical properties. Even after it has been stretched to more than three times its normal dimensions (equivalent to a stretch rate of 200 % or more), and even when folded more than 200,000 times (bending radius 0.1 mm or less), the change in resistance value was only about 1.2-fold. Figure 1 (A) is a photo of the conductive wires used as LED wiring. If wiring resistance varies significantly during stretching, the brightness of the LED light will also vary greatly. Using the newly developed spring-shaped conductive wires, however, there was almost no change in LED brightness even when stretched 200 % or more. This indicates that the change in resistance value during stretching is very small. Moreover, when an ordinary elastic conductive wire is stretched and allowed to contract, a relaxation phenomenon of electrical resistance occurs and it takes time until the resistance value stabilizes. The developed conductive wire, on the other hand, has more stable properties. There is less variation in resistance during stretching and contraction and it takes less time for the resistance value to stabilize. This makes it usable as signal wiring for sensors and the like (Fig. 1 (B)).

|

|

Figure 1: Highly elastic spring-shaped conductive wire and its electrical properties

(A) LED brightness when the highly elastic spring-shaped conductive wire was used as LED wiring (stretch rate 200 % or more)

(B) Variation in resistance value when the conductive wire was repeatedly stretched from 0 % to 200 % |

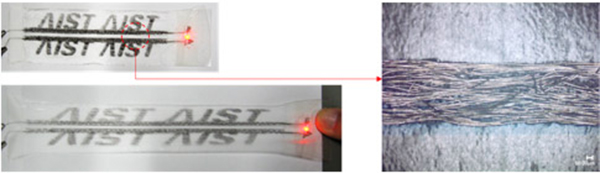

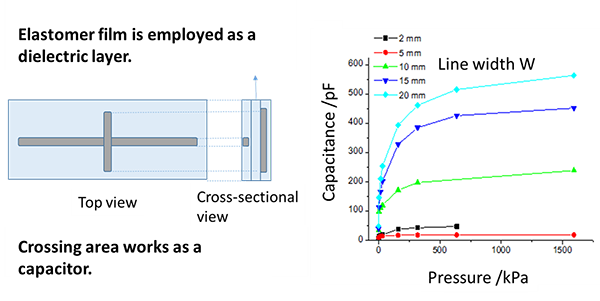

Because it is essential that wearable devices can be manufactured into any shape, it is also necessary to be able to form high-elasticity electrodes into any pattern. In this research, a method was developed to form highly elastic electrodes by imparting a high orientation property to conductive short fibers and then patterning them (Fig. 2). It is possible to make a highly elastic capacitor as in Fig. 3 because large-area electrodes can be formed using the developed method. Because the capacitor is flexible, it can be used as a capacitive pressure sensor, which detects changes in capacitance resulting from mechanical changes such as a pressure change.

|

Figure 2: Oriented short-fiber electrode

Highly elastic oriented short-fiber electrode connected to an LED and stretched to double its ordinary length (left)

Microscopic photo of oriented conductive short fibers on a highly elastic resin sheet (right) |

|

Figure 3: A device made with oriented short-fiber electrodes

Structure of the capacitor made with highly elastic oriented short-fiber electrodes (left)

Relationship between capacitance and pressure applied to sensor (right) |

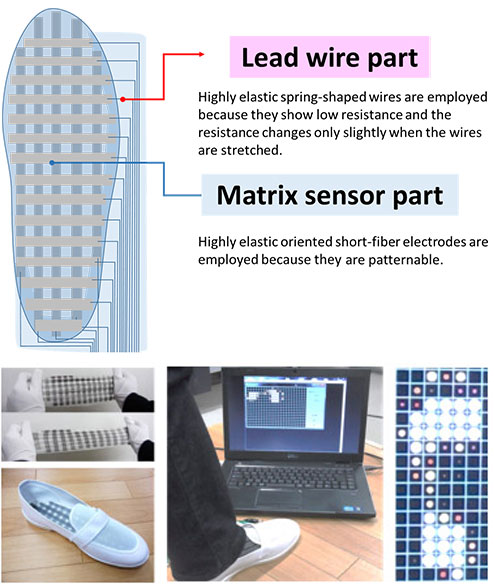

To date, most pressure sensor matrix sheets have been flexible but not elastic. The researchers, therefore, formed a matrix of capacitive pressure sensors using the developed highly elastic oriented short-fiber electrodes. By using highly elastic spring-shaped conductive wires as signal wires, a sensor matrix sheet was created that has both high elasticity and high bending durability (Fig. 4). Even after stretching to 200 % and being folded 200,000 times at a bending radius of less than 0.1 mm, this sensor sheet provided stable operation. These elasticity and durability meet specs for practical use. It can even be used under severe conditions. For example, the sensor sheet could be placed inside a shoe, where it would bear the body weight of the wearer for many hours and be repeatedly deformed. Thus, it could be used as a sensor for measuring the pressure distribution on the sole of the shoe.

|

|

Figure 4: Shoe-sole pressure sensor sheet using highly elastic spring-shaped wires and highly elastic oriented short-fiber electrodes |

The researchers will develop efficient production processes so that the technology can be manufactured on an industrial scale. They will also work on total design of everyday health management systems, elder care monitoring systems, etc. using the developed sensor matrix sheets.