– New membrane separation activated sludge process using factory infrastructure –

Researchers) INABA Tomohiro, Senior Researcher, HORI Tomoyuki, Senior Researcher, Environmental Ecophysiology Research Group, Environmental Management Research Institute

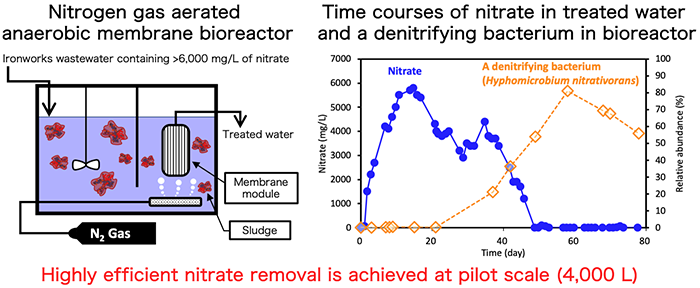

- Development of a treatment process combining nitrogen gas aeration with the membrane bioreactor, and demonstration in a 4,000-L pilot plant

- A denitrifying bacterium (Hyphomicrobium nitrativorans) is involved in the removal of high concentrations of nitrate

- Expectations for practical application in a wide range of industrial sectors where the treatment of wastewater with high nitrate concentrations is a problem

Schematic of the nitrogen gas aerated anaerobic membrane bioreactor

Leakage of nitrogen compounds such as nitrate contained in wastewater into the environment can have serious impacts on the natural environment, such as eutrophication of lakes, marshes, rivers, and oceans, and contamination of groundwater. For these reasons, the nitrogen components contained in domestic wastewater are biologically removed in sewage treatment plants by microorganisms called activated sludge. The left side of Figure 1 shows the schematic image of nitrate removal using a nitrogen gas-aerated anaerobic membrane bioreactor. Denitrifying bacteria convert nitrate into nitrogen gas, while using organic matter in the wastewater as a nutrient source.

In the metalworking industry, metal products are washed with acids, such as nitrate, in the manufacturing process, resulting in wastewater that is poor in organic matter but contains high concentrations (6,000 mg/L or more) of nitrate, making wastewater treatment essential. However, only low concentrations (typically less than 100 mg/L) of nitrate can be removed by the general activated sludge process, making it difficult to apply the traditional process directly to effluent from the metalworking industry. This difficulty in treating the high-strength effluent has been a factor in restricting the smooth product manufacturing. In addition, the only options for nitrate removal, other than biological treatment, are the physical and chemical methods, such as electrodialysis, which have high energy costs, so more efficient wastewater treatment methods are needed.

Researchers in AIST, in collaboration with JFE Steel Corporation and Kurita Water Industries Ltd, developed a treatment process for ironworks wastewater containing high concentrations of nitrate by combining nitrogen gas aeration, methanol addition, and the membrane bioreactor.

Nitrate contained in wastewater can cause eutrophication of rivers, lakes, and marshes, as well as contamination of soil and groundwater, thus appropriate treatment is needed to prevent its release into the environment. This research developed a new wastewater treatment process using nitrogen gas aeration as the existing ironworks infrastructure. A demonstration test using a 4,000-L pilot was successful in efficiently treating ironworks wastewater containing more than 6,000 mg/L of nitrate. In addition, microbial analysis revealed that a denitrifying bacterium was involved in the effective nitrate removal. This new process is expected to be used in various industrial sectors where the treatment of wastewater with high nitrate concentrations is a problem.