– Development of a technology enabling to avoid the risk of reduced power generation in high voltage systems –

Researchers: JONAI Sachiko, Visiting Researcher, MASUDA Atsushi, Deputy Director, Research Center for Photovoltaics, MATSUI Takuya, Leader, Advanced Processing Team of the research center, KOIDA Takashi, Chief Senior Researcher, and SHIBATA Hajime, Invited Senior Researcher, Compound Semiconductor Thin Film Team of the research center

- Enables adequate suppression of output decrease induced by the application of high voltages, which may occur at megawatt-class solar power plants

- Easy technology transfer with a simple method that consists simply of forming a transparent conductive film on the photovoltaic cell surface

- Technology with high tolerance to performance decrease due to electrode breakage of photovoltaic cells

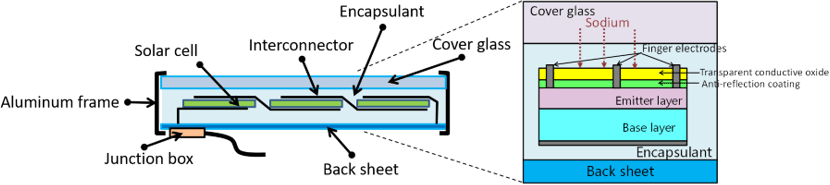

Cross sectional structure of a photovoltaic module (left) and enlarged view of a crystalline silicon photovoltaic cell with a transparent conductive film that can adequately suppress potential-induced degradation (right)

Large-scale solar power plants with a scale of hundreds of megawatts or more tend to use higher system voltages to reduce power loss during transmission of electricity, and system voltages around 1500 V are becoming common.

In solar power plants with a high system voltage, the potential difference between the high potential side of photovoltaic cells and the aluminum frame of the photovoltaic module is around 1000 V, and this large potential difference has been reported to result in potential-induced degradation (PID). The occurrence of PID greatly reduces photovoltaic module performance in a short period of months to years, but there are still many unclear points regarding the mechanism.

The researchers have developed a technology that can adequately suppress PID that leads to a large drop in photovoltaic module performance in a short time, simply by forming a transparent conductive film on the photovoltaic cell surface.

Countermeasures such as increasing the resistivity of the photovoltaic module encapsulant or changing the composition of an anti-reflection coating of photovoltaic cells have been reported. These countermeasures slow but are unable to completely suppress the progression of PID, and there are also issues such as increased manufacturing costs and lower initial conversion efficiency. Conventional crystalline silicon photovoltaic cells have an anti-reflection coating on the cell surface. The developed technology shields the electric field applied to that anti-reflection coating by forming a transparent conductive film on it, which enables to adequately reduce PID. This inexpensive and simple method can avoid the risk of reduced power generation, and also produce little or no drop in the initial conversion efficiency. Furthermore, when electrodes on the photovoltaic cell surface become broken, the carriers at the breakage points generally cannot be collected. In the developed cell, however, carriers at the breakage points can also be collected via the transparent conductive film, which also effectively suppresses power generation decrease. Moreover, conventionally used inexpensive photovoltaic cell materials as well as cell and module manufacturing processes can be used as is, so it is expected that manufacturing costs will not increase and the technology can easily be transferred to industries.