Update(MM/DD/YYYY):08/21/2007

Development of a Total Fluorine Analyzer that is several hundred times as sensitive as a conventional analyzer

- Makes possible the easy and prompt analysis of environmental samples and industrial products -

Highlights

This refined analyzer can measure fluorine concentrations in gas, liquid, and solid samples in less than 20 minutes with a level of sensitivity that is several hundred times better than that of conventional models. As no sample pretreatment is required, a potential source of contamination and error is eliminated.

As a simple and rapid method for the safety testing of various industrial products is developed, the refined analyzer can also be used for the sensitive analysis of total bromine, as required by the EU Restriction of Hazardous Substances Directive (RoHS). It will also help meet future international regulations on fluorinated compounds, such as the EU’s Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) legislation.

The analyzer is suitable for a variety of applications, including the sensitive analysis of fluorine-containing impurities, such as perfluorooctane sulfonate (PFOS), in environmental samples, industrial raw materials, pharmaceuticals, and high-purity reagents and gases, and in lifecycle assessments as well as the analysis of wastes.

Summary

Nobuyoshi Yamashita (Senior Research Scientist), Yuichi Miyake (Post-doctoral Research Scientist), Hisao Hori (Leader of the Potential Pollutants Group), Ko Harada (Director of the Research Institute for Environmental Management Technology), and Hiroyuki Yoshikawa (President of the National Institute of Advanced Industrial Science and Technology [AIST]) have, in collaboration with Masanori Hirai (President of Dia Instruments Co., Ltd.), developed a fully automatic total fluorine-analyzing system with an unprecedented high level of sensitivity.

This analyzing system is based on the conventional halogen analyzer that uses combustion ion chromatography (CIC). A higher level of sensitivity was achieved by replacing the fluorine-containing materials in part of the equipment and in the gas-supply line, which have the potential for fluorine contamination, with non-fluoropolymer materials and by using higher purity gases for the sample combustion. Our new system permits the quantitative analysis of absolute amounts of 0.6 ng fluorine.

The analyzer allows easy, rapid, and sensitive analyses of the total fluorine and organic fluorine compounds that are present in various environmental samples and industrial products. It can also be used to analyze compounds that contain chlorine or bromine. Thus, it is suitable for ensuring compliance with the EU RoHS directive and with potential future regulations on fluorinated compounds, such as the EU’s REACH legislation.

The details of this new technology will be presented at Japan's Exhibition of Analytical Instruments Solutions 2007, which will be held in Makuhari Messe from August 29 to 31, and in lectures and presentations at international conferences.

|

Combustion Ion Chromatography (CIC) |

Social Background of the Development

Various kinds of persistent organic fluorine compounds are used in huge quantities in the manufacture of highly sophisticated electronic products, such as semiconductors and fluoropolymers, and functional pharmaceuticals. The management of the residues of the fluorine-containing chemicals in these products and in the environment has become an urgent task. PFOS is one of many such fluorine compounds, and there is growing concern about its persistence and diffusion in the environment and accumulation in living organisms. PFOS is also a candidate to be considered as a persistent organic pollutant (POP), and the global reduction of PFOS levels is therefore desired.

Japanese research on PFOS lags behind that of certain other nations and is preoccupied with environmental research data, but to date more than 500 research reports have been published in other countries. Scientists who are involved in advanced research are well aware that the comprehensive management of several hundreds of PFOS-related compounds is vital.

In the future, most synthetic chemical substances that contain fluorine or bromine are likely to be subject to international surveillance as a result of regulations such as REACH. A fast and easy method for analysis and screening is required for safety management within the chemical industry, for the appropriate development of industry, and for environmental analyses. However, no reliable technique is yet available for the sensitive analysis of all fluorine-containing compounds.

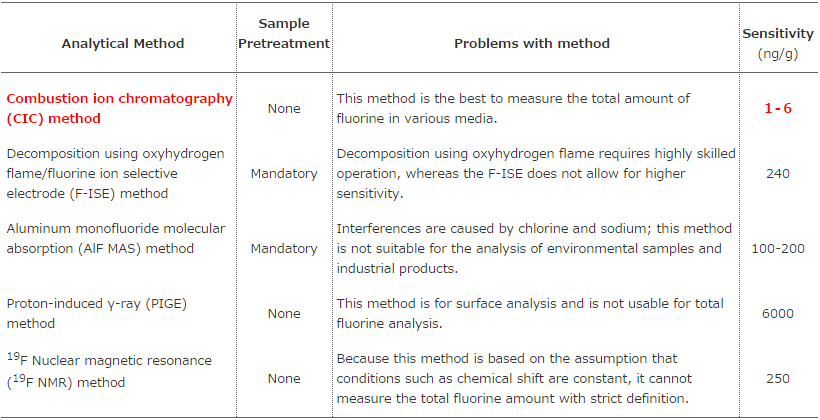

Comparison of Methods to Analyze Total Fluorine

|

|

History of Research

Before the PFOS issue attracted worldwide attention, AIST developed environmental analysis technology in collaboration with researchers in the U.S.A. In 2003, AIST also developed the first method for the analysis of PFOS-related substances in ocean waters and clarified the level of ocean pollution on a global scale in 2004. This technique for the sensitive analysis of water samples, the details of which were published in international journals in 2005, is still the world’s most sensitive analytical method, and an international standardized analysis method that is based on this technique is currently being formulated with support from 12 countries.

While conducting advanced research on the analysis of individual fluorine-containing compounds, AIST is also engaged in research and development on a highly reliable and sensitive analytical method for testing total fluorine amounts that is suitable for screening and monitoring the several tens of thousands of synthesized fluorine-containing compounds that are produced and used in industry.

The existing CIC equipment (Automatic Quick Furnace – 100, AQF-100) that is marketed by Dia Instruments Co., Ltd. suffers from deteriorating sensitivity, because many parts of the instruments are made of fluoropolymers, and there are various fluorine-containing impurities in the gases that are used for combustion. We have constructed a high-performance system to purify the combustion gases, examined all of the materials for possible fluorine contamination, reviewed the equipment design, rebuilt a combustion system that is free of fluoropolymers, and increased the sensitivity of the ion chromatography.

Some of these achievements are the result of research conducted as part of a subsidized project, the “Development of a Dissolution Test Method and an International Standard for Hazardous Chemical Substances,” which has been conducted by the New Energy and Industrial Technology Development Organization (NEDO).

Details of Research

The two main problems with the existing method of analyzing organic fluorine compounds are, first, the difficulty in completely converting organic fluorine into elemental fluorine and, second, the high degree of background contamination. In this research, we eliminated the impurities from the combustion gas and replaced the parts of the instruments that were made of fluoropolymers, the source of contamination within the equipment, with other materials to decrease the background fluorine concentration of the whole system. We also achieved a nearly 100% decomposition rate.

We successfully reduced the concentration of impurities in the combustion gas to less than one-tenth the previous level by using a high-purity gas (with a purity of higher than 99.9995%) and by adsorbing residual impurities using an activated carbon filter with a large surface area. At the same time, we made the gas container, gas regulator, and gas line free of fluoropolymers by building them with stainless steel or polyetherether ketone (PEEK). Tubes and tube connectors are made of polyethylene, and the syringes of the constant-rate pump are made of ceramics. With these changes, the background concentration of the equipment decreased to less than one-fifteenth of its previous level.

The sensitivity of the analyzer has been improved by about 100 times, compared with off-the-shelf equipment, and we have solved most of the problems inherent in existing analytical methods, such as the need for pretreatment and the consequent loss of volatile compounds, by optimizing a system that combines a microbore system with an inner diameter of 2 mm (half that of the conventional system) and a mass sample-introduction method that has a volume about 20 times as large as that used in conventional ion chromatography.

These measures have enabled us to achieve an equipment sensitivity of 0.6 ng in terms of the absolute amount of fluorine and to perform analyses with sensitivities as high as 3 ng/L (ppt) for liquid samples and 0.3 ng/g (ppb) for solid samples.

To date, we have built up analytical data by using real environmental samples (seawater, sediment, living organisms, etc.) and industrial materials (circuit board, plastics, etc.). Some of these results have been published in the international periodical Journal of Chromatography A (2007, 1143, pp. 98-104, and 2007, 1154, pp. 214-221).

Fully automatic analytical equipment that incorporates our new technology has already been developed. In addition to its application as an easy and rapid sensitive screening method for fluorine residues in diverse industrial products, this equipment can also contribute directly to domestic industry, which needs to respond promptly to the RoHS and REACH regulations.

Future Schedule

This equipment is highly versatile and is suitable for screening many of the products that are subject to REACH regulations, because it permits sensitive analyses of total fluorine, total chlorine, total bromine, and total iodine.

In the future, we aim to build up sufficient experimental data to permit the equipment to be used for the analysis of bromine-containing fire retardants and impurities in chemical compounds and pharmaceuticals. At the same time, we will develop a range of applications for the equipment, so that inexpert end users will be able to operate it. With AIST’s potential in national and international standardization, we are also considering the development of our technique as a standard analytical method.

Details will be disclosed at the following events.

-

The 24th International Symposium on Halogenated Environmental Organic Pollutants and POPs (Hotel Okura, September 2-7)