Hideaki Nagai (Senior Researcher), Kunimitsu Kataoka (Researcher), and Junji Akimoto (Leader), Crystal and Materials Processing Group, Advanced Manufacturing Research Institute (Director: Masanobu Awano) of National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi), have developed a particle size control technology to increase charge-discharge capacity of titanium oxide material H2Ti12O25 (HTO), a negative-electrode material for lithium-ion secondary batteries.

This technology enables high charge-discharge capacity per HTO weight of approximately 250 mAh/g by controlling the particle size of sodium titanate, the raw material for synthesis of HTO. This exceeds 225 mAh/g obtained by HTO without particle size control. Because the improvement in capacity and rate characteristics can be achieved by simple modification of existing manufacturing processes, it is expected to lead to higher capacity and lower costs of automobile-use lithium-ion secondary batteries used for electric vehicles and hybrid vehicles.

Details of this technology will be presented at the 13th International Nanotechnology Exhibition & Conference (nano tech 2014) to be held from January 29 through 31, 2014 at Tokyo Big Sight (Koto-ku, Tokyo).

|

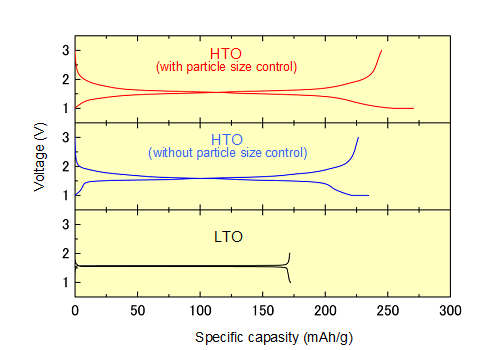

(Figure) : Comparison of charge-discharge curves for particle-size-controlled HTO,

HTO without particle size control, and an existing negative-electrode material, lithium titanate Li4Ti5O12 (LTO)

(Counter electrode: Metallic lithium; Current density: 10 mA/g) |

Recently, large lithium-ion secondary batteries are drawing attention for automobile and stationary power source usage. In these applications, in addition to improvement of input-output properties and energy density, the securing of safety, longer life, and lower cost are important. There are expectations for the utilization of lithium-ion secondary batteries using oxide materials as negative electrodes. However, the charge-discharge capacity per unit weight of lithium titanate (Li4Ti5O12), the current negative-electrode material, is low at 175 mAh/g and a high-capacity negative-electrode oxide material exceeding 200 mAh/g with voltage at the same level as lithium titanate is desired.

AIST has conducted research on the synthesis of titanium oxides using soft chemical synthesis, a low-temperature synthesis process, and evaluation of the structures and properties of these compounds. In the course of this research conducted jointly with Ishihara Sangyo Kaisha, Ltd. (ISK), it has developed a new, high-capacity titanium oxide negative-electrode material, HTO, exceeding 200 mAh/g with voltage at the same level as the existing material (AIST Press Release, October 25, 2010). Since then, research and development have been conducted in particle size control technology and manufacturing processes aiming for further increase in capacity and improvements in the input-output properties of HTO.

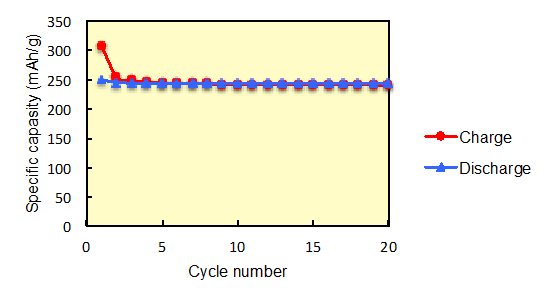

The developed technology uses a soft chemical synthesis method, a method that modifies its chemical composition without any skeletal structure change of the starting material. It utilizes the strong relationship of particle morphology between the raw material, Na2Ti3O7 powder, and the final product, HTO. First, a pulverizing technology, a particle size control technology that can easily be incorporated into the existing manufacturing process, was used to conduct particle size control of Na2Ti3O7 powder (average particle diameter: 2 µm). The skeletal structure of the particle size controlled Na2Ti3O7 powder was then stabilized through heat treatment (average particle diameter: 0.2 µm), and acid-treated at 60 °C to produce H2Ti3O7, a previous step material of HTO. Particle-size-controlled HTO is manufactured by heating this between 200 and 300 °C. Figure 1 indicates the charge-discharge cycle characteristics of particle-size-controlled HTO. Although the first cycle of charge capacity at room temperature was 307 mAh/g and discharge capacity was 249 mAh/g, indicating a charge-discharge efficiency of 81%, charge capacity was 244 mAh/g, discharge capacity was 243 mAh/g, and charge-discharge efficiency was almost 100 % on its fifth cycle, confirming a reversible charge-discharge characteristics. Stable charge-discharge was displayed in subsequent cycles.

|

Figure 1 : Charge-discharge cycle characteristics of particle-size-controlled HTO

(Temperature: 25 °C; Counter electrode: Metallic lithium; Current density: 10 mA/g) |

The charge-discharge capacity of this particle-size-controlled HTO is approximately 90 % of the theoretical capacity of HTO (274 mAh/g) derived from crystal structure analysis and is almost equal to the capacity estimated from the amount of lithium insertion and removal by chemical reaction (256 mAh/g). These results suggest that the potential ability of HTO has been brought out by particle size control.

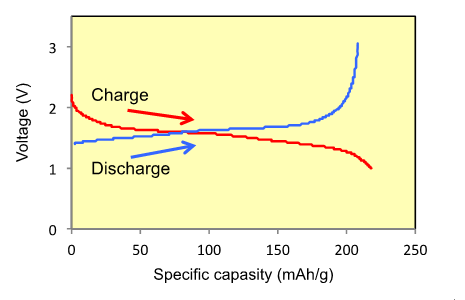

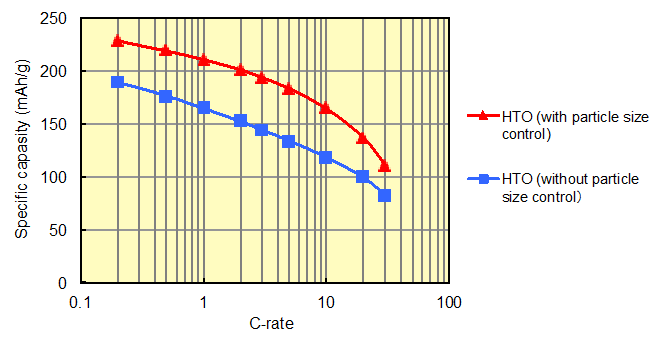

Furthermore, when a prototyped electrode with an electrode composition close to practical use (83 % active materials, 10 % conductive assistant, 7 % binder) was evaluated at 25 °C, a charge-discharge capacity in excess of 200 mAh/g was maintained for a current density of 220 mA/g, equivalent to 1 hour-rate (1C) (Fig. 2). In addition, as indicated in Fig. 3, the rate characteristics of the prototyped electrode have been improved by particle size control. As an example, when the charge rate was 1C, a capacity of 164 mAh/g without particle size control increased to 210 mAh/g, in excess of 200 mAh/g, with particle size control. As described above, the charge-discharge capacity and the rate characteristics of HTO have been improved by the developed particle size control technology.

|

Figure 2 : Charge-discharge curve using prototyped electrode

(Temperature: 25 °C; Counter electrode: Metallic lithium; Current density: 10 mA/g)

Capacity at the start of charge and discharge measurement is indicated as 0. |

|

Figure 3 : Charge rate characteristic using prototyped electrode

(Temperature: 25 °C, Counter electrode: Metallic lithium, Discharge: 0.2C

[Assumed capacity 220 mAh/g]) |

The researchers will cooperate with ISK, which collaborated in the development of HTO, to establish the mass-production technology of HTO, and proceed with preparations for providing samples to the industry, including battery manufacturers.