Update(MM/DD/YYYY):10/04/2010

Proving High-Speed, High-Temperature Operation of Diamond Power Device

- Superiority of diamond as a next-generation semiconductor material has been confirmed -

Points

-

Operation of a power switching device with diamond diodes was confirmed for the first time.

-

High-speed and low-loss operation was confirmed and practical applications in the future are expected.

-

Expectations for energy savings as a future power device

Summary

Shinichi Shikata (Director) and Hitoshi Umezawa (Senior Research Scientist), the Diamond Research Laboratory of the National Institute of Advanced Industrial Science and Technology (AIST; President: Tamotsu Nomakuchi), have fabricated a prototype diamond diode rectifier with ruthenium (Ru) electrodes for power device application in collaboration with Tsuyoshi Funaki (Professor), Division of Electric, Electrical and Information Engineering, Graduate School of Engineering, Osaka University (President: Kiyokazu Washida). Using this element, the switching performance of a diamond semiconductor diode rectifier was measured for the first time and high-speed, low-reverse-recovery current operation was confirmed.

Diamond is well-known material filled with many excellent characteristics including great hardness and thermal conductivity, high optical tranparency, and excellent chemical stability. Due to its excellent semiconductor properties such as high dielectric breakdown field and high carrier mobility, diamond has potential applications as high-voltage, low-loss, fast-response power semiconductor devices for electric power control. A diode rectifier is a basic component of power devices. In this research, diamond Schottky barrier diodes, combining diamond semiconductors with a Ru Schottky electrode previously developed at AIST, are used to fabricate the rectifier. Silicon semiconductor MOSFETs (a type of transistor) comprise the drive circuit, and a double-pulse method was used to measure the switching recovery properties of the diamond diode rectifier. The results confirmed high-speed switching at only 0.01 microseconds and low-reverse-recovery current (low loss) of just 40 A/cm2.

The result will be published on Sept. 10, 2010 in "Electronics Express" (http://www.elex.ieice.org/index.html), an English language journal of the Institute of Electronics, Information and Communication Engineers, and will also be presented at the Fall Meeting of the Japan Society of Applied Physics on Sept. 15 in Nagasaki.

|

|

|

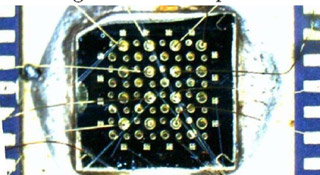

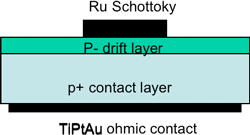

Figure 1: Top view (left) and schematic illustration (right) of fabricated diode rectifier |

Social Background of Research

Power devices are crucial semiconductor devices for power control of electric equipment and fundamental to energy-saving technologies as inverters become commonplace. In recent years, high-voltage, high-current operation of power devices has become technically possible, and power devices are spreading rapidly, for example being used to drive motors of hybrid automobiles, and have a market scale worth reported 2 trillion yen. Reducing the use of electric energy by enhancing the performance of power devices is considered one of the key energy innovation technologies to be addressed in the "Cool Earth-Innovative Energy Technology Program" established by the Ministry of Economy, Trade and Industry for massive reductions in CO2 emissions.

Silicon (Si) semiconductors are currently used in power devices, but because of its material properties, devices are facing limits on heat resistance, voltage resistance, current density, and power loss. Thus, new materials are being developed such as silicon carbide (SiC) and gallium nitride (GaN). Diamond is also one of these new materials, but it has some unique properties: diamond itself is a heat sink material that disperses heat, it withstands high temperatures and its current density rises at high temperatures. Because of these unique properties, diamond power devices are expected to achieve high-temperature operation without a cooling system, as well as high voltage resistance and high current density.

History of Research

Among all materials, diamonds have some most excellent properties, including their hardness, thermal conductivity, elastic modulus, optical transmittance, chemical stability, and electrochemical properties. AIST conducts research to develop new applications of diamonds by combining those properties with semiconductor properties. It has already developed large-area mosaic wafers of single crystal diamond as a materials technology (AIST press release on March 1, 2010). AIST also does basic research on various devices that use diamonds and on related materials. It has succeeded in developing a diamond diode with a Ru Schottky electrode, which has excellent heat resistance, low electric resistance, adhesiveness, and good Schottky junction (AIST press release on January 8, 2009).

Part of this research was supported by an energy saving innovative technical development project of the New Energy and Industrial Technology Development Organization.

Details of Research

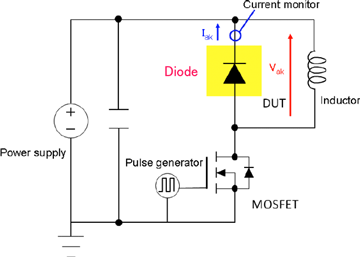

The diamond Schottky barrier diode used for this research was prepared by combining diamond semiconductors with a Ru Schottky electrode (Fig. 1, right). This diode is capable of high-temperature operation, needs no cooling system, and can operate at high current densities because of the properties of diamond and the Ru electrode. Seven small diodes are connected in parallel by wire to increase total current (Fig. 1, left); the diodes are sealed with a refractory resin to realize high-temperature operation. Using commercially available Si MOSFETs as drive transistors, a circuit was put together as shown in Fig. 2, thus fabricating the diode rectifier.

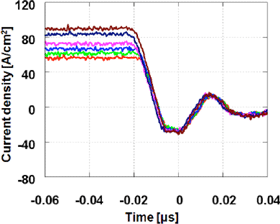

Switching properties were measured by a double-pulse method, which is not affected by temperature changes in the device. The results show characteristics of a unipolar diode, which does not depend on current values, as shown in Fig. 3. The findings confirmed high-speed switching at only 0.01 microseconds and low-reverse-recovery current of just 40 A/cm2, which was dependent only on parasitic inductance of the measurement circuit and a high di/dt in high-speed switching operation, thus indicating that energy loss was suppressed. The above results indicate that this diode will always operate stably at high speeds.

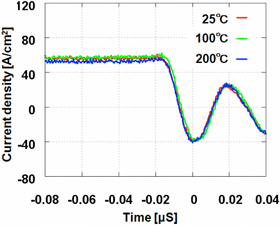

Measurement of temperature dependence (Fig. 4) shows that recovery current is not temperature dependent and that switching speed does not change with temperature. Stable operation was observed at up to 200°C and operation was good even without cooling.

Figure 2: Diagram of circuit used for measurement

|

|

Figure 3: Stable switching properties at various current values (red through brown lines)

|

Figure 4: Temperature dependence of switching properties

|

|

|

Future Schedule

This research proved the performance of the diamond diode rectifier with high voltage resistance, high output, high speed, and low loss, and the aim hereafter is to realize a 100 A class device (1 cm2 class) capable of the high currents needed for practical power devices. For that purpose, research will be conducted on technologies for producing large-area substrates, technologies for growing low-defect, high-quality drift layers, device design technologies and so on. AIST also aims to achieve energy saving power devices by researching not only Schottky barrier diode rectifiers but also diamond transistor elements at the same time.