Shinichi Shikata (Deputy Director of the Diamond Research Center and Leader) and Hitoshi Umezawa (Research Scientist), the Device Development Team, the Diamond Research Center (Director Naoji Fujimori) of the National Institute of Advanced Industrial Science and Technology (AIST) (President: Hiroyuki Yoshikawa), have developed rectifying diodes for power devices using ruthenium (Ru) and diamond. They are operational at high temperatures exceeding 400°C for long periods.

Diamond is a top-quality material that offers hardness, thermal conductivity, optical transparency in wide range of wavelength, and chemical stability. As a semiconducting material, it has excellent dielectric breakdown and mobility. The expected merits are not confined to machinery applications; we also envisage applications for optical parts, electrochemistry and semiconductor devices. In particular, if adopted in semiconductor power-control devices, high performance would be realized in the form of high-temperature non-cooled devices associated with high-voltage and high-current-density.

In this study, rectifying diodes as essential elements of power devices were experimentally fabricated and long term stability was demonstrated at high temperatures. Until now, it has generally been believed that the electrodes of Schottky diodes cannot withstand high-temperature operation for extended periods. Among the materials that we explored for a Schottky electrode, Ru performed exceptionally in addressing the four challenges of thermal stability, low resistance, good adhesion, and the feasibility of Schottky junctions. It is also stable at high temperature. New rectifying diodes were experimentally fabricated using Ru for the Schottky electrode and diamond for the substrate. The devices were confirmed to be free of degradation through operation tests at 400°C for 1,500 hours and at 500°C for 250 hours. At self-heating temperatures such as from 200 to 250°C, the test data suggests that the devices would operate for several decades without cooling. If this technology is introduced in future, energy-saving non-cooled power devices would be possible. The results of the present study will be published in Applied Physics Express online, Japan Society of Applied Physics, Jan. 9, 2009: http://www.jsap.or.jp/publish/apex/index.html.

|

Semiconductor power devices are essential for power control of electrical equipment; they are the basis for energy conservation technology as inverters popularized. Now that large-current operation has recently become possible, these devices are rapidly finding new applications including motor drive units for hybrid cars. It is reported that the market size is currently about 2 trillion yen. There is an urgent need for innovation to reduce electric power consumption by developing advanced power device technology; the issue is included in the "Cool Earth - Innovative Energy Technology Plan" of the Ministry of Economy, Trade and Industry for greatly reducing CO2 emissions.

Today, silicon (Si) is exclusively used in power devices, but the material has inherent problems with regard to thermal stability, high-voltage operation, power loss, and current density. To resolve these problems, new materials such as silicon carbide (SiC) and gallium nitride (GaN) are now being developed. Diamond is another promising material with specific properties: it is in itself the best-known heat-sink material, withstands high temperatures, and has the distinctive feature of the current becoming greater at higher temperatures. For application to power devices, these strong merits make diamond a promising material for realizing high-temperature non-cooled devices with high-voltage, large-current capabilities.

The Diamond Research Center, AIST, is exploring possibilities for fully utilizing the semiconducting characteristics of diamond in combination with its superior properties, which include excellent hardness, thermal conductivity, elastic modulus, optical transparency, chemical stability, and electrochemical properties. As part of the material technology, developments are also being made in the technology for fabricating large-sized single crystals of diamond (AIST press release on March 20, 2007). For the utilization of diamond in power devices, various types of devices and materials are presently being studied.

This study aimed at developing Schottky rectifying diodes with large-current, high-temperature, and non-cooled operation. So far, such metals as aluminum (Al), gold (Au), molybdenum (Mo), and platinum (Pt) and a compound material, tungsten carbide (WC), have been widely used to form Schottky junctions with diamond. Although the Pt Schottky junction has good thermal stability compared with the other metals, it is not likely to be used due to unavoidable interfacial peeling. WC has not yet been fully examined for thermal stability, but it is reported that, at 500°C, the device characteristics can change within 3 hours. Other demerits of WC are that its resistivity is more than an order of magnitude larger than those of the other metals, and a metal like gold is additionally needed for wire connections.

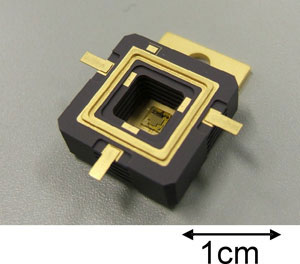

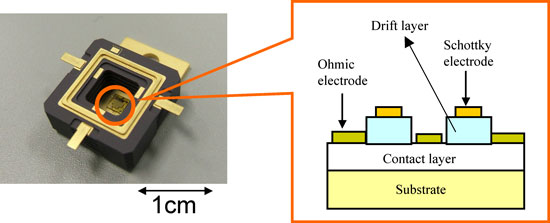

Figure 1 shows the external appearance of a fabricated rectifying diode and the schematic illustration of cross-section of the developed part. An active layer is stacked on the diamond substrate, and then both Ohmic and Schottky electrodes are formed on it. The Ohmic electrodes are made of heat-tolerant triple metal layers of Ti/Mo/Au.

In this study, various metals were examined as candidates for Schottky electrode material to realize high-temperature operation. For metals endowed with excellent electrical and thermal conductivity, various characteristics were examined with Schottky junctions, including adhesion strength and thermal stability. Note that there has been no reported metal having excellent properties with regard to thermal and electrical conductivity, adhesiveness, and Schottky junction characteristics. Needless to say, interfacial reaction at high temperatures should not cause any degradation. This study is the first to show that ruthenium (Ru) satisfies all the criteria, and to demonstrate the fabrication of diodes using ruthenium and diamond.

|

Figure 1 Overview of the Schottoky Barrier Diode with the cross-section schematic(right).

(2 x 2mm device chip is indicated by the circle.) |

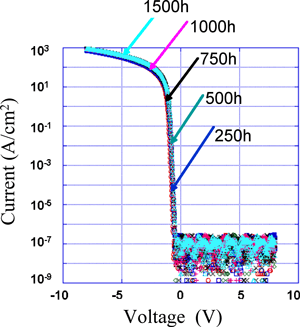

The diodes using ruthenium as Schottky electrodes showed no degradation after high-temperature storage tests at 400°C for 1,500 hours and 500°C for 250 hours (Fig. 2). The various properties of the Schottky junctions were studied in detail, and no variation in the properties was observed after 1,500 hours at 400°C. At self-heating temperatures such as from 200 to 250°C, the data indicates that the device would operate for several decades without cooling. This suggests the possibility of reducing the electrical power consumed for cooling, which has been considered unavoidable in power devices.

|

|

Figure 2 The IV characteristics of a Ru/diamond Schottky barrier diode after the storage at 400°C for 1500 h

|

For practical application to power devices, diamond devices must have an area as large as 1 cm2 or more in order to handle large currents. To meet this objective, we will work on the technology for fabricating large-area substrate, for high-quality epitaxial film growth, and for device design. While the present study focuses on the development of Schottky diodes, we will also pursue transistor devices that can be used as energy-saving power devices without cooling.