Researchers) ITASAKA Hiroki, Researcher, LIU Zheng, Chief Senior Researcher, MIMURA Ken-ichi, Senior Researcher, HAMAMOTO Koichi, Group Leader, Energy Storage Materials Group, Innovative Functional Materials Research Institute

- Successful thinning of multilayer capacitor structure using dielectric nanocube monolayer film

- Developed a multilayer structure using graphene as an inner electrode instead of conventional metal electrodes

- Contributing to miniaturization of multilayer ceramic capacitors

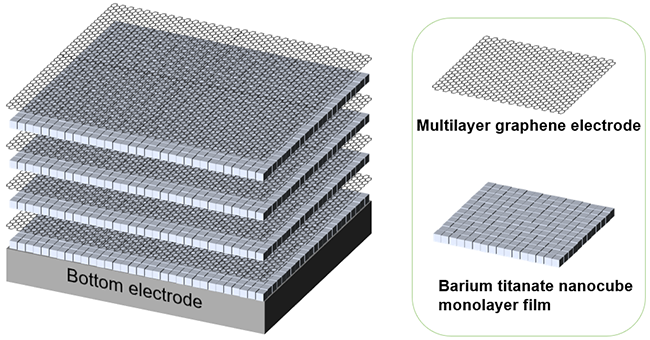

Schematic diagram of the developed stacked structure

As the performance of portable devices such as smartphones and tablets has rapidly increased in recent years, there is a demand to further miniaturize the electronic components built into these devices. The interior of an MLCC consists of dielectric and electrode layers alternately stacked. Increasing the number of the layers by reducing the thickness of each layer is an important development issue for the miniaturization and performance improvement. To reach the target, a number of research studies are conducted in industry and academia by using various combinations of dielectric and electrode layer materials. Current MLCCs uses BTO powder, the raw material for the dielectric layer, and metal powder, the raw material for the electrode layer, which are sintered at a high temperature more than 1000 ℃. However, the thickness of the dielectric layer and electrode layer has already reached less than 1 µm, approaching the size of the raw material powder particles (several hundred nm), and the insulation properties of the dielectric layer have deteriorated due to the thinning of the layers. Therefore, the development of a new multilayer process technology to reduce the thickness of the dielectric and electrode layers to the nanoscale maintaining the reliability of MLCCs has been a challenge.

Researchers at AIST have developed a process technology for alternately stacking cubic single-crystal (nanocube) monolayers of barium titanate (BTO), a dielectric material, and multilayer graphene sheets.

The technology developed in this research makes it possible to fabricate an extremely thin multilayer structure consisting of monolayers of two-dimensionally ordered BTO nanocubes of about 20 nm in size and multilayer graphene sheets of 2–3 nm in thickness, and is expected to be a fundamental technology to realize a dramatically thin multilayer structure with alternating dielectric and electrode layers in a multilayer ceramic capacitor (MLCC).