– Carbon nanotubes provide uniform electrical conductivity and high shape retainability –

Researchers: HAYASHI Masahiko, Specialist for Specific Subject (Research), and TOMONOH Shigeki, Invited Senior Researcher, CNT-Application Research Center and Team of Application for Carbon nanotubes Composite (TACC)

- Development of technology for effectively dispersing multi-walled carbon nanotubes (CNTs) into resin to make a composite

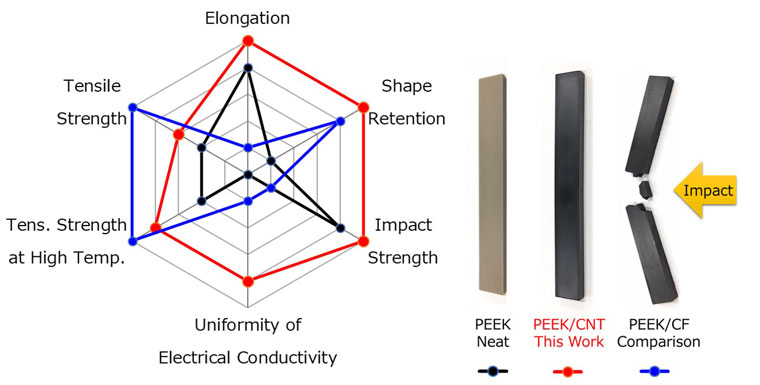

- Improved mechanical strength (tensile strength, elongation) at high temperatures with no loss of impact strength (toughness)

- Multi-walled CNTs provide uniform electrical conductivity and high shape retainability (low coefficient of linear thermal expansion, low creep).

PEEK/CNT composite with high impact resistance

Poly(ether ether ketone) (PEEK) exhibits the highest level of heat resistance among thermoplastic super-engineering plastics that can be melt-processed. It also has excellent fatigue, environmental, chemical, and flame resistance. This resin is lighter than metal and is widely used in electrical and electronic components, and in automotive and aerospace applications. In recent years, a carbon fiber (CF) filler is added to PEEK to provide electrical conductivity for electrostatic discharge protection, strength, and thermal conductivity. However, adding a filler often makes resins susceptible to cracking under impact.

The researchers, in collaboration with Sunarrow Ltd., have developed a technology to make a composite of multi-walled CNTs and PEEK with improved mechanical strength at high temperatures, high shape retainability, and uniform electrical conductivity, while maintaining impact strength (toughness) comparable to the resin matrix. This technology uses an improved kneading and forming technique. It significantly improves toughness over PEEK/CF composites with comparable electrical conductivity, making it possible to produce PEEK composites for practical application with both electrical conductivity and toughness. If used to replace metal components in automobiles and airplanes, they can reduce their overall weight and contribute to energy savings.