Update(MM/DD/YYYY):12/12/2016

Memory Stability of Non-volatile Magnetic Memory (STT-MRAM) Improved Two-fold

- Accelerate development for practical application of high capacity STT-MRAM–

Points

-

Memory stability improved two-fold by the development of an ultrathin layer of cobalt

-

Realized perpendicularly magnetized tunnel junction that has low resistance characteristics of memory elements

-

Accelerated development of the under-20-nm generation of high capacity STT-MRAM

Summary

Kay Yakushiji (Leader), the Metal Spintronics Team, the Spintronics Research Center (Director: Shinji Yuasa), the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi), has improved by two-fold the memory stability of perpendicularly magnetized tunnel magnetic resistance (TMR) elements which are used in a next-generation memory device, a spin-torque-switching magnetic random-access memory (STT-MRAM).

Perpendicularly magnetized TMR elements are composed of a “storage layer” responsible for information memory and a “reference layer” which is the judgment standard for storage layer information. The storage layer must have retention (memory stability) so as not to lose stored information. In the newly developed perpendicularly magnetized TMR element, memory stability was improved two-fold using an interface structure composed of an iridium layer and an ultrathin cobalt layer as a part of the storage layer. An element size of less than 20 nanometers (nm) is necessary to replace conventional semiconductor memory (DRAM), and the present results are expected to realize 19 nm element size high integration STT-MRAM and be applied to commercialization in data storage and mobile devices

Details of the results will be published in the online edition of “Applied Physics Express.”

|

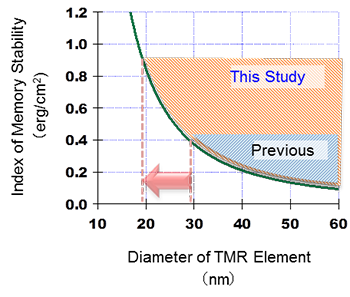

Correlation diagram of storage layer stability and producible perpendicularly magnetized TMR element size

In the developed storage layer, enhancing the storage layer stability indicator two times over the conventional value allowed 19 nm element size. |

Social Background of Research

TMR element based STT-MRAM has such features as non-volatility, high speed, and high rewrite endurance. In particular, the fact that it does not require electrical power to maintain memory, because it is non-volatile, has helped it to gain attention as an energy-saving new generation universal memory. The high potential of perpendicularly magnetized TMR element based STT-MRAM has already been broadly demonstrated both in Japan and abroad, and at present technology development for achieving device application is being advanced actively. As for devices, taking advantage of its non-volatility, STT-MRAM is expected to be used in peripheral memory combined with storage or high capacity main memory surpassing conventional semiconductor memory (DRAM). However, with STT-MRAM, the smaller the element size is, the harder it is to ensure memory stability. Currently, with the structure and materials of perpendicularly magnetized TMR elements which are mainstream in Japan and abroad, storage stability is leveling off at the 30 nm size, and it is becoming difficult to achieve sizes under 20 nm which are necessary for DRAM alternatives.

History of Research

AIST is conducting research and development of high performance perpendicularly magnetized TMR elements which are the core technology for realizing high capacity STT-MRAM. Since developing the world’s first STT-MRAM prototype based on perpendicularly magnetized TMR elements in collaboration with Toshiba Corporation and others in 2008, AIST has been the world leader in developing STT-MRAM. At present, AIST has reduced memory element sizes to 30 nm, and is energetically advancing research of high impact DRAM alternative STT-MRAM, towards practical application. However, with the structure and materials of mainstream perpendicularly magnetized TMR elements, storage stability is leveling off at the 30 nm element size. Therefore, AIST decided to pursue research and development for improving memory stability with new structure and materials.

The present research and development was conducted with the support of the research project “Development of Rare-Metal-Free Ultra-High Magnetic Anisotropic Thin Film by Single Atomic Layer Design” (Research Leader; Kay Yakushiji), of the Japan Science and Technology Agency Strategic Basic Research Program (PRESTO) “New Materials Science and Element Strategy” (Research Supervisor: Hideo Hosono).

Details of Research

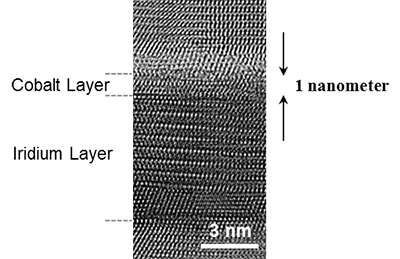

The researcher introduced a thin iridium film and an ultrathin cobalt film to the storage layer. Previously, it was problematic that indium and cobalt would cause interdiffusion easily when an iridium thin film and a cobalt thin film are layered. Yet, by developing a thin film formation technology with carefully devised thin film formation conditions, the researcher has succeeded in suppressing interdiffusion at the atomic level, forming a very sharp interface. Figure 1 shows an electron microscope image of the actual thin film structure which was formed. The cobalt thin film layer which formed on the top of the iridium thin film layer is just 1 nm thick.

|

|

Figure 1: Electron microscope image of a cross section of the iridium thin film and the ultrathin cobalt thin film formed on the top of it |

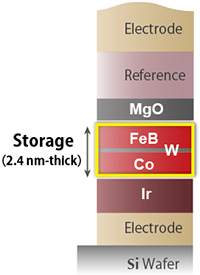

The overall thin film structure of the developed perpendicularly magnetized TMR element is shown in Fig. 2. An iridium thin film and an ultrathin cobalt thin film with a sharp interface are formed in the lower part of the element, with various thin films layered on the two films. The three integrated layers of cobalt (Co)/tungsten (W)/iron born (Fe-B) enclosed by a yellow line form the storage layer, and this integrated storage layer serves as one memory of STT-MRAM. When using materials and structures not used in any perpendicularly magnetized TMR elements so far, such as the iridium thin film and the ultrathin cobalt thin film, it is necessary to add new performance without losing various characteristics possessed by conventional perpendicularly magnetized TMR elements. That point was the focus of the developed element as well, so tungsten was inserted above the cobalt thin film as shown in Fig. 2 in order to achieve both a low resistance-area (RA) value and a high magnetic resistance (MR) ratio equivalent to conventional perpendicularly magnetized TMR elements. Memory stability is determined by the “volume” and the “anisotropic energy” of the storage layer. With the developed element, by improving the anisotropic energy two-fold over previous technology, memory stability was improved two-fold without changing the volume of the storage layer. That characteristic makes it possible to achieve 19 nm size STT-MRAM. It also fulfills the low resistance-area characteristic required of element size under 20 nm. It is expected that these results will greatly accelerate the practical application development of high capacity STT-MRAM.

|

|

Figure 2: Cross-section structural diagram of the developed perpendicularly magnetized TMR element |

Future Plans

The developed film formation technology can be applied to perpendicularly magnetized films with other materials and crystal orientations, and has potential for a wide range of applications. The researcher will strive to achieve higher memory stability based on this technology (larger numbers on the vertical axis of the “Correlation diagram of storage layer stability and producible perpendicularly magnetized TMR element sizes”), with the aim of establishing mass production technology for high capacity STT-MRAM.