-This smart grid technology reduces power loss by detecting malfunctions in panels –

Collaborative research team for communication and control of smart grid (Leader: Tetsuya Higuchi), the Information Technology Research Institute (Director: Satoshi Sekiguchi) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Tamotsu Nomakuchi), has developed a communication technology which uses the direct current (DC) power line of a solar panel as a communication line, and the team has substantiate the principle of the technology using a prototype system. The communication technology helps monitor the power generation in each solar panel, which is useful for the maintenance of the panel and the prompt detection of malfunctions in the panel.

The monitoring unit of the developed communication system is small and can be placed in the terminal box of a solar panel. It is also inexpensive to produce (the target cost of a monitoring unit when it is mass-produced is less than 200 yen). The system does not require additional wiring work because the existing DC power lines from the solar panels are used for communication. Furthermore, malfunctions in a panel can be detected more easily than before because changes in the power generated in each panel can be displayed on the screen of a central unit. A high-efficiency power converter circuit has also been developed for distributed maximum power point tracking (MPPT). The circuit allows us to extract the maximum power from each solar panel. We can therefore reduce the effect of factors such as sunlight conditions on the panels. A high DC-DC power conversion efficiency of 98% is achieved with this circuit.

Since this new smart grid technology for solar power generation allows trouble-free operation of solar panels with high efficiency at small cost, it is expected to promote the use of solar power generation systems, thus contributing to the realization of a low-carbon society.

The technology will be exhibited at the "Smart Grid Exhibition 2010" to be held from June 16, 2010, at Tokyo Big Sight.

|

|

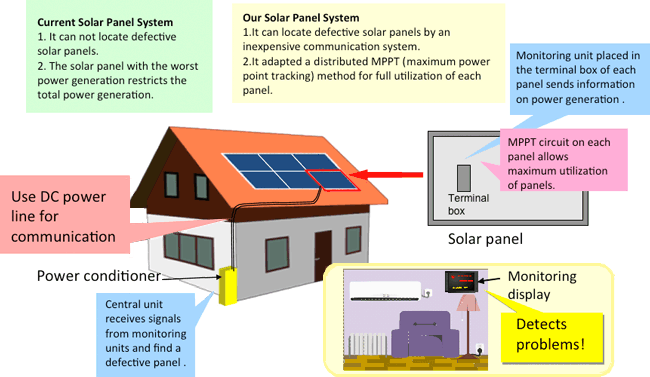

Figure: New system in which the DC power line of a solar panel is used for communication

|

The dissemination of solar power generation is very important for promoting the use of renewable energy and for realizing a low-carbon society. A solar panel is considered to have a life span of 20 years. However, it is difficult to prevent failures in a solar panel during its entire life span, because it is an industrial product. In addition, with the current photovoltaic systems, it is difficult to identify the defective panel. Therefore, it is desirable to realize a monitoring method that neither imposes additional cost on solar panels nor needs the installation of a new communication line.

Once a solar power generation system is placed on the roof of an ordinary house, it is generally not inspected, and it is difficult to identify a defective panel even when a fall in the output of photovoltaic system suggests the malfunction of the system. If the problem is left unaddressed, the amount of generated power is less than what should be generated, and the photovoltaic system may not be fully utilized. Consequently, the widespread use of solar power generation may be impeded by the reduced cost-effectiveness.

Since last year, AIST has focused on the development of a communication technology for transmitting data on power generated by a solar panel through the DC power transmission line of the panel. This would facilitate inexpensive monitoring of the power generation without installing new communication lines. Progress has been made in the research and development of such technology by focusing on points including the development of a new communication system, the downsizing of the communication unit for neat installation in a solar panel, and the use of commercially available and inexpensive electronic parts.

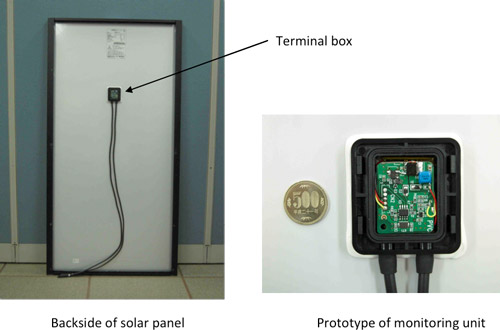

In Japan, communication functions are not added to each solar panel, because it would lead to a price hike. In this study, DC power lines are exploited for communication, a noise-robust communication system has been developed by applying CDMA, and a small monitoring unit are placed in the terminal box of a solar panel as shown in Fig. 1. Data of each panel including voltage, current, and temperature are transmitted en bloc through the DC power line to the central unit on the power conditioner side (Fig. 2).

|

|

Figure 1: Monitoring unit placed in the terminal box of a solar panel |

|

|

Figure 2: Configuration of the entire communication system |

The monitoring unit for communication comprises commercially available, inexpensive electronic parts. Figure 3 shows the monitoring unit (left) and the central unit (right). A very low frequency is used in this communication system, therefore, the system will not affect wireless communication.

|

|

Figure 3: Prototype communication boards for the monitoring unit (left) and the central unit (right) |

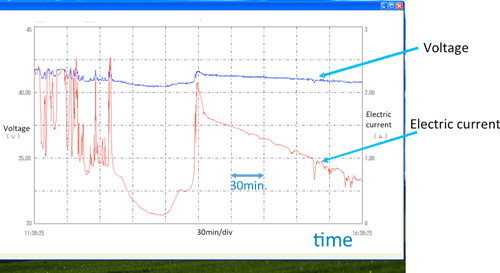

Using the communication system, changes in the voltage and current of solar panels are monitored as shown in Fig. 4. The monitoring of each panel allows us to, for example, locate defective panels in the photovoltaic system.

|

|

Figure 4: Screen shot of the monitor screen |

We have also developed a switching circuit system for distributed MPPT to maximize the power output from each panel. The transistors in switching circuits are switched on/off. In the developed system, the energy loss due to the switching can be effectively recovered by the compact circuit. Therefore, a top-class DC-DC power conversion efficiency of 98% is achieved.

The prototype system can be improved by focusing on points such as the enhancement of noise-robustness, downsizing, and cost reduction. We intend accelerating technology transfer for its commercial production. We also have a plan to develop an algorithm to detect malfunctions by processing the information obtained by monitoring solar panels.