Update(MM/DD/YYYY):08/06/2010

A Thermoelectric Power Generation Module has been Developed Using New Materials

-The module can be used at high temperatures of over 300 ºC and is expected to promote the thermoelectric waste heat recovery in a moderate temperature range –

Points

-

The new thermoelectric materials use abundant metals, namely barium, gallium, and tin.

-

Both the p-type and n-type materials have nearly identical composition, allowing easy module design and use of the same manufacturing process.

-

The module has achieved a power-generation efficiency of about 4%, equivalent to those of the modules with conventional materials.

Summary

Atsushi Yamamoto (Leader), Thermoelectric Energy Conversion Group, the Energy Technology Research Institute (Director: Yasuo Hasegawa) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Tamotsu Nomakuchi), has developed new thermoelectric materials composed of barium (Ba), gallium (Ga), and tin (Sn) and fabricated a prototype thermoelectric module for power generation using the materials, in collaboration with Toshiro Takabatake (Professor), Graduate School of Advanced Sciences of Matter, Hiroshima University (President: Toshimasa Asahara), Tsuyoshi Koyanagi (Professor), Graduate School of Science and Engineering, Yamaguchi University (President: Takuya Marumoto), KELK Ltd. (KELK; President: Satomi Nashiwa), and DENSO Corporation (DENSO; President: Nobuaki Kato). The module has been demonstrated to have power generation performance equivalent to that of existing thermoelectric power-generation modules, with an output power of 1.7 W and a generation efficiency of about 4% for a temperature difference of 300 ºC (330 ºC on the hot side of the module and 30 ºC on the cold side).

The thermoelectric materials have advantages over currently used thermoelectric materials: they can be used at temperatures higher than the applicable temperatures of conventional thermoelectric materials; both p-type and n-type thermoelectric materials can be fabricated by a slight change in material composition; and the materials do not contain rare metals, the prices of which fluctuate due to resource scarcity. The materials are expected to be applied to factory waste-heat-recovery power-generation systems.

Details of the results will be presented at the International Conference on Thermoelectrics (ICT 2010) held on May 30 to June 3, 2010, at Shanghai, China.

|

|

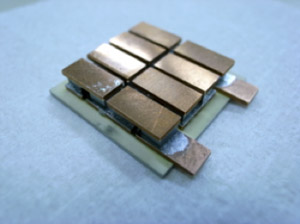

Fig. 1 A prototype of eight-pair thermoelectric power generation module using the new Ba-Ga-Sn-based thermoelectric materials

|

Social Background of Research

Japan relies on imports for most of its primary energy supplies, and the efficient use of fossil fuels, such as petroleum and natural gas, is an important issue. However, about 70% of primary energy is lost to the environment as waste heat energy in the processes of conversion and use. Power generation using recovered waste heat is expected to increase energy-utilization efficiency.

Waste heat from large concentrated sources is used for power generation via a steam recovery system and a turbine. Recovering waste heat from small, distributed sources involves many issues including high recovery costs, and the development of new technologies is expected.

In recent years, thermoelectric power generation has been attracting attention as a technology for waste-heat-recovery power generation, as it has a simple system configuration suitable for downsizing. However, the performance of thermoelectric materials needs to be improved to increase the performance of thermoelectric power generation. In order to improve the performance of the materials, it is necessary to achieve both electrical conductivity as high as that of metal and thermal conductivity as low as that of glass. Research is being conducted at many research institutions to develop metal and semiconductor thermoelectric materials and demonstrate their use in thermoelectric power-generation modules.

History of Research

AIST is developing high-performance thermoelectric power generation modules as a technology for the efficient use of unused waste heat from homes, buildings, factories, and vehicles. As the upper service temperature limit of practical bismuth telluride-based thermoelectric materials is only 250 ºC, AIST has been working to develop thermoelectric materials and thermoelectric power generation modules applicable to heat sources in a moderate temperature range of 300 to 400 ºC. In a FY2002-FY2006 project, “Development of a High-efficiency Thermo-electric Conversion System,” of New Energy and Industrial Technology Development Organization (NEDO), AIST conducted research and development of an evaluation technology for thermoelectric power generation modules in collaboration with Engineering Advancement Association of Japan.

Since June 2009, AIST, Hiroshima University, Yamaguchi University, KELK, and DENSO have improved the performance of Ba-Ga-Sn-based thermoelectric materials expected to show enhanced performance in the temperature range of 200 to 300 ºC and fabricated prototype modules as part of “Research and Development of High-performance Nano-structured Thermoelectric Materials Using Caged Compounds” project (Project Manager: Toshiro Takabatake) of NEDO. Based on a study in the material composition through single-crystal growth experiments at Hiroshima University and a study in fabrication conditions for polycrystalline samples at Yamaguchi University, the performance of the thermoelectric materials was improved. The present results were obtained by applying AIST’s fabrication and evaluation technologies for thermoelectric power generation modules to these materials.

Details of Research

Commercially available bismuth telluride-based thermoelectric materials can be applied to waste heat at 200 to 250 ºC and have a power generation efficiency of about 5%. In order to develop a system to efficiently produce electricity from waste heat, the power generation efficiency needs to be further increased. Because the maximum efficiency depends on the performance of a thermoelectric material, it is required to develop new high-performance thermoelectric materials including those with controlled nanostructures.

Though Ba, Ga, and Sn are metallic as a single material, they form a compound semiconductor with a cage-shaped crystalline structure when they are mixed in a certain composition ratio. Cage compounds like this compound are commonly called clathrates. The presence of atoms, Ba atoms in this case, loosely bound in cages enables heat conduction to be suppressed. Because of this, the compound is expected to have higher performance than bismuth telluride-based thermoelectric materials. The Ba-Ga-Sn-based clathrate can be used as either a p-type or n-type thermoelectric material by slightly changing the basic composition ratio. The p-type and n-type materials have the same thermal and mechanical properties, allowing easy design of modules combining both types and use of the same manufacturing process. This gives the materials advantages over other thermoelectric materials.

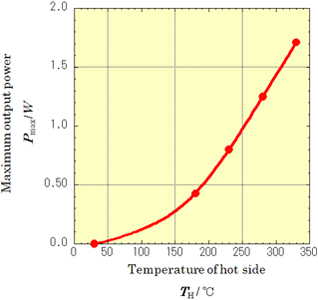

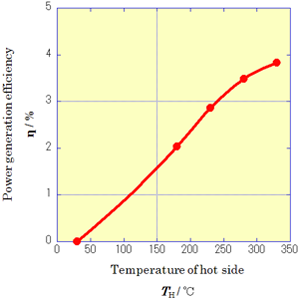

Both of p-type and n-type Ba-Ga-Sn polycrystals were surface treated to prevent diffusion. The p-type was cut into a 5.0-mm-square, 2.5-mm-thick thermoelectric element, and the n-type into a 4.1-mm-square, 2.5-mm-thick thermoelectric element. A half-skeleton-type thermoelectric power generation module was fabricated by attaching a metal electrode to eight pairs of p and n elements (Fig. 1). This prototype module has external dimensions of 28.0 mm × 28.0 mm × 5.5 mm and weighs about 15 g, including a substrate. Power-generation characteristics were measured by using AIST’s thermoelectric power generation module evaluation system for a maximum temperature difference of 300 ºC; the evaluation was carried out by heating the top of the module to 330 ºC, with the bottom temperature at 30 ºC, in a nitrogen atmosphere. The open-circuit voltage, the internal resistance, the maximum output power, and the heat flux for the temperature difference of 300 ºC were about 1.03 V, 155 mΩ, 1.71 W, and 44.2 W, respectively (Fig. 2). The power-generation efficiency calculated from these data was 3.9% (Fig. 2).

At present, the thermoelectric figure of merit is about 0.8 for the n-type material and that of the p-type material is about 0.3. There is potential for further improvement in material performance. The temperature difference for the maximum thermoelectric figure of merit is over 200 ºC and higher than those for bismuth telluride-based thermoelectric materials. Therefore, the materials have potential for further development as new high-performance thermoelectric materials for use in a moderate temperature range.

|

|

Fig. 2 Power generation characteristics of the eight-pair thermoelectric power generation module using the Ba-Ga-Sn-based thermoelectric materials

Left: Relationship between temperature of the hot side and maximum output power

Right: Relationship between temperature of the hot side of the module and power generation efficiency

The temperature of the cold side was constant at 30 ºC. |

Future Schedule

The module developed by the joint team uses polycrystalline materials. A small single crystal being developed by Hiroshima University and DENSO has higher performance with a thermoelectric figure of merit of over 1. Our next steps are to further improve the performance of the thermoelectric materials by using the single crystal, and to develop a highly efficient module for power generation using unused waste heat at about 300 ºC with a conversion efficiency of over 10%, and a high-performance waste-heat power-generation system.