Kay Yakushiji (Senior Research Scientist), Metal Spintronics Team (Leader: Hitoshi Kubota), the Spintronics Research Center (Director: Shinji Yuasa) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Tamotsu Nomakuchi), has developed a high-performance perpendicularly magnetized tunnel magnetoresistance (TMR) element that functions as a memory cell for large-capacity spin-injection magnetoresistance random access memory (Spin-RAM).

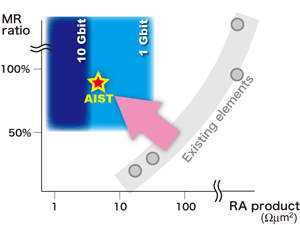

Because Spin-RAM does not require electricity to retain data and can reduce the power consumption of IT equipment, there are expectations for the development of large-capacity (1-Gbit or more) Spin-RAMs. In order to develop a large-capacity Spin-RAM with a memory capacity of over 1 Gbit, it is necessary to develop a perpendicularly magnetized TMR element that has not only a magnetoresistance (MR) ratio higher than 50% to generate a large output signal, but also low electrical resistance for impedance matching with peripheral circuits. Assuming a Spin-RAM over 1 Gbit with a cell size of about 65 nm in diameter, impedance matching requires the TMR elements to have a resistance-area (RA) product of about 30 Ωμm2. However, there have been no reports on such perpendicularly magnetized TMR elements. Achieving a high MR ratio in a low-RA product region has been an important issue to be resolved. The perpendicularly magnetized TMR element developed at AIST has succeeded in achieving an MR ratio as high as 85% in low-RA product region as low as about 4 Ωμm2 (marked by the star in Fig. 1). This technology enables the circuit design of large-capacity Spin-RAMs of 5 Gbit or more.

Details of this technology will be published online in Applied Physics Express on May 14, 2010.

|

Figure 1 Readout performance (RA product, MR ratio) of perpendicularly magnetized TMR elements and capacity of feasible Spin-RAMs

This development enables circuit design of Spin-RAMs of 5 Gbit or more. |

In recent years, there has been strong demand for the production of non-volatile (i.e. electricity is required only to write and read data, but not to retain data) semiconductor memories that can replace current dynamic random access memories (DRAMs). DRAMs are commonly used in electronic devices such as personal computers and cell phones. Having properties such as non-volatility, high-speed read/write capability, and high rewrite durability, TMR element-based Spin-RAMs are being developed as a type of universal memory that is superior to conventional semiconductor memories. Limited-capacity Spin-RAMs that have several to several tens of Mbits capacity and use an in-plane magnetized TMR element as the memory cell have been test-fabricated and have demonstrated high potential. However, there is strong demand to develop a large-capacity Spin-RAM, because large (Gbit-class) capacity is required to replace the DRAM used in computers.

AIST has been conducting research and development in order to realize a large-capacity Spin-RAM. It has demonstrated for the first time the basic operations of a TMR element with magnetization oriented in-plane and has improved the memory retention performance of this type. A TMR element with magnetization oriented perpendicular to the plane of the film has a lower write current than an in-plane magnetized TMR element. Because of this, research and development of the perpendicularly magnetized TMR is being actively conducted in Japan and abroad.

In 2008, AIST succeeded for the first time in the world in test-fabricating a perpendicularly magnetized TMR element-based Spin-RAM jointly with TOSHIBA and others and demonstrated that both the memory retention performance and a low-write current required for Gbit-class Spin-RAMs could be achieved in principle. However, the issue of improving the readout performance required for working memory remained to be addressed. Both a low RA product for impedance matching and a high MR ratio for large output signals had to be achieved to improve the readout performance. There was an urgent need to achieve simultaneously a low RA product and a high MR ratio for perpendicularly magnetized TMR elements. AIST has been conducting research and development with the goal of achieving an RA product of no more than 30 Ωμm2 and an MR ratio of at least 50%.

This research and development is a part of the Spintronics Nonvolatile Technology Project of the New Energy and Industrial Technology Development Organization, which started in 2006.

|

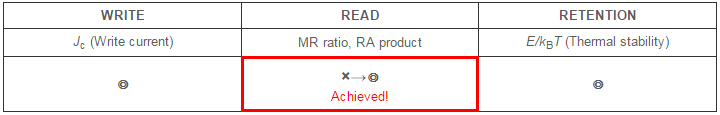

Table 1 Status of achievement of performance goals for perpendicularly magnetized TMR elements required for Spin-RAM memory cells

|

|

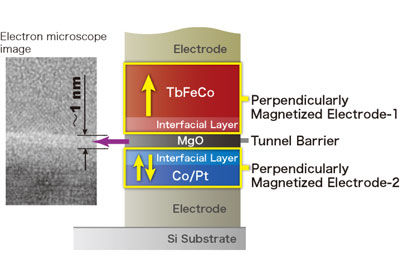

The technological key points are twofold: (1) development of a technology to planarize ultra-thin films forming a TMR element; and (2) development of an interfacial layer that induces high spin-polarization. Figure 2 (right) is a schematic of the layered structure of the perpendicularly magnetized TMR element that was developed. The perpendicularly magnetized electrode layer 1 is formed of a terbium-iron-cobalt (TbFeCo) layer and an interfacial layer (details are mentioned later), and the perpendicularly magnetized electrode layer 2 is formed of layered cobalt/platinum (Co/Pt) films and an interfacial layer. The electrode layers are magnetized perpendicularly to the substrate as shown by the arrows. Magnetoresistance manifests itself as an electrical resistance change reflecting the difference in magnetization alignment of two electrode layers (parallel or anti-parallel). Information is stored accordingly.

The thickness of the magnesium oxide (MgO) layer used as the tunnel barrier must be less than 1.3 nm to achieve an RA product of no more than 30 Ωμm2. This is equivalent to a thickness of five atomic layers. It is extremely difficult to form such an ultra-thin tunnel barrier uniformly without defects. We worked to develop a thin-film formation process to planarize the surface of the tunnel barrier layer and the perpendicularly magnetized electrode layer 2 under the tunnel barrier layer (Fig. 2, right) at an atomic level. We have succeeded in forming a perpendicularly magnetized electrode layer 2 with a surface that is flat at the atomic level, as well as an ultra-thin (about 1 nm), uniform tunnel barrier layer (MgO layer) (Fig. 2, left). As a result, we have achieved a world-class RA product of about 4 Ωμm2 for perpendicularly magnetized TMR elements.

|

|

Figure 2 Electron microscope image of a cross-section of the perpendicularly magnetized TMR element developed (left), and a schematic of the cross-sectional structure (right)

The development of ultra-thin film planarization technology and a high spin-polarization inducing interfacial layer has led to success in achieving both a very low RA product and a high MR ratio.

|

In addition, we have developed an interfacial layer combining a crystalline cobalt-iron (CoFe) alloy and an amorphous cobalt-iron-boron (CoFeB) alloy. We have succeeded in promoting crystallization of the amorphous layer by introducing CoFe into the interfacial layer normally formed only of CoFeB. Crystallization of the amorphous layer is essential for obtaining higher MR ratios. We believe that in the perpendicularly magnetized TMR element that we have developed, a low RA product (about 4 Ωμm2) and a high MR ratio (85%) have been simultaneously achieved as a result of the introduction of this new interfacial layers.

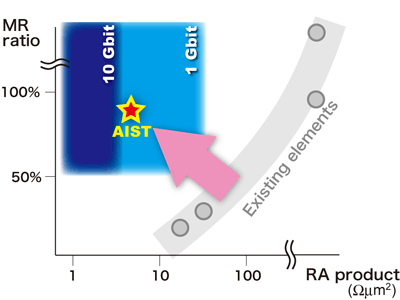

As a result of this development, we have succeeded for the first time in achieving excellent readout performance, as described above, and an MR ratio of at least 50% and an RA product of less than 30 Ωμm2, both of which are required to achieve a 1-Gbit memory capacity, in perpendicularly magnetized TMR elements (Fig. 3). We have also succeeded in improving the MR ratio to 85% and reducing the RA product to about 4 Ωμm2, making it possible to design circuits for Spin-RAMs with a memory capacity of over 5 Gbit, thus exceeding the target capacity. This achievement is expected to significantly advance the development of large-capacity Spin-RAMs using perpendicularly magnetized TMR elements.

|

Figure 3 Readout performance (RA product, MR ratio) of perpendicularly magnetized TMR elements and capacity of feasible Spin-RAMs

The star indicates the performance of the element that we have developed, and the gray circles indicate the performance of existing elements (reported values). |

The developed technology can be applied to perpendicularly magnetized layers of other materials and crystalline orientations and has a very wide range of potential applications. We will work to achieve higher MR ratios based on this technology and to establish a mass-production technology for large-capacity Spin-RAMs.