- Materials for chemicals, pharmaceuticals to be produced from a by-product of biodiesel fuel production -

Hiroshi Habe (Research Scientist) and Tokuma Fukuoka (Research Scientist) of the Bio-chemical Processes Group (Leader: Keiji Sakaki), the Research Institute for Innovation in Sustainable Chemistry (Director: Masaru Nakaiwa) of the National Institute of Advanced Industrial Science and Technology (AIST) (President: Hiroyuki Yoshikawa) have developed a new technique to effectively produce D-glyceric acid from glycerin, which is in abundant supply due to, for instance, the proliferation of biodiesel fuel (BDF).

In the process of producing BDF from vegetable oils, approximately 10 wt% of glycerin is produced as a by-product, and the total amount of glycerin produced worldwide is expected to be around a million tons a year. Therefore, an effective use for this surplus glycerin has long been sought, and AIST, in collaboration with a private company, has developed and published a technique to convert glycerin into a functional surfactant.

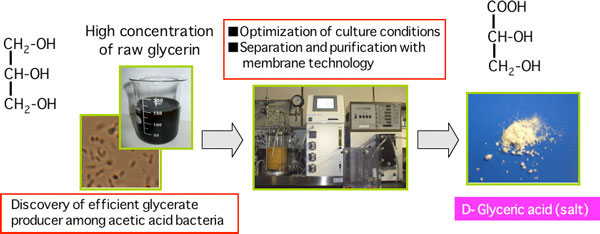

We have developed a new method for producing D-glyceric acid effectively by oxidizing glycerin with an acetic acid bacterium, a highly oxidative microorganism.

Although D-glyceric acid and its derivatives have excellent biological functions, including an action to accelerate alcohol metabolism, they are expensive because industrial methods have not been established for their production. If they can be produced at low cost, wide uses will be expected, including raw materials for chemical products such as bioplastics, pharmaceuticals for alcohol metabolism acceleration or liver disease treatment, and raw materials for cosmetics.

Details of this technique will be presented at the Annual Meeting of the Japan Society for Bioscience, Biotechnology, and Agrochemistry 2009, held at Fukuoka International Congress Center and Marinemesse Fukuoka on March 28 and 29, 2009.

|

|

Effective production of D-glyceric acid from highly concentrated glycerin produced as a by-product |

Recently technologies for producing BDF and various other chemical products from vegetable oils have been promoted. However, a surplus of glycerin that is produced as a by-product of the technologies becomes a problem. Applications of glycerin that have been developed are in the main production processes of chemical products for general-purpose use utilizing chemical techniques, and there are difficulties with regards to the yields of the reactions and the purity of the products.

On the other hand, processes for producing chemical products having high functionality using biotechnological methods such as fermentation and enzymatic conversion have been examined, but there have been problems such as the lack of availability of highly concentrated glycerin as a raw material and the high cost of separation and purification of products.

Earlier, AIST developed a technique to convert crude glycerin into a functional surfactant in collaboration with a private company (Press release on September 11, 2008). During the research process, we noticed D-glyceric acid, a derivative of glycerin, and started research and development in the production of D-glyceric acid using microorganisms. We have also been developing energy-saving separation and purification technologies using separation membranes. By combining the two technologies, we succeeded in developing an effective, low-cost production method.

This study was supported by FY2008 Grant for Industrial Technology Research of the New Energy and Industrial Technology Development Organization.

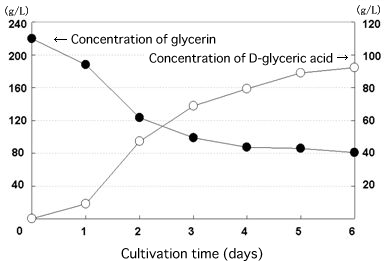

Vinegar (acetic acid) is produced by oxidizing ethanol with acetic acid bacteria. We found a Gluconobacter strain among acetic acid bacteria that effectively converts highly concentrated glycerin into D-glyceric acid by oxidation. There are some reports of the production of D-glyceric acid using microorganisms, but the amount of product yield is only 57 g/L (gram/liter) at maximum. In most cases the growth of bacteria is inhibited if glycerin exists in a concentration higher than 20% and, therefore, highly concentrated glycerin has hardly been used as a raw material. From the viewpoint of the promotion of the use of glycerin produced as a by-product, we charged highly concentrated (22%) glycerin, which is more than twice the ordinary concentration, as a raw material, and optimized culture conditions and the amount of aeration. As a result, we found that the amount of produced D-glyceric acid greatly rises, and we obtained approximately 90 g/L of D-glyceric acid (Fig. 1).

|

|

Fig.1 Fermentative production of D-glyceric acid from highly concentrated (22%) glycerin |

In the experiment described above, purified glycerin was used. However, crude glycerin produced as a by-product in BDF production processes usually contains several percents of methanol and other organic impurities, which were both found to inhibit the production of D-glyceric acid. We solved this problem by heating the crude glycerin under reduced pressure to remove the methanol, and then treating it with activated charcoal to remove the organic impurities.

Another feature of our technique is the use of a membrane that selectively permeates ions for separation and concentration of the product. A microorganism reaction solution contains not only D-glyceric acid, but also many unwanted substances including residual glycerin, dihydroxyacetone, which is a by-product of this reaction, and ingredients of the culture medium. Membrane separation enabled us to remove approximately 90% of these unwanted substances, concentrate the desired product easily in a short time, and obtain more than 200 g/L of D-glyceric acid solution. Adding calcium chloride to the solution yielded a precipitate of calcium salt of D-glyceric acid of high purity (Fig. 2).

|

|

Fig. 2 Calcium salt of D-glyceric acid produced using our technique |

We will develop applications for D-glyceric acid and its derivatives. We intend to develop a technology system to realize a sustainable society, in which a wide range of chemical products are produced from renewable resources as an alternative to petroleum.