- Establishing the technology to produce high quality single walled carbon nanotubes for industrial applications without aftertreatments -

|

|

Figure 1. An origami crane made from a non-purified high quality SWNT sheet (sheet thickness: approximately 9 micrometers)

|

A research team headed by Dr. Takeshi Saito from the Research Center for Advanced Carbon Materials (Sumio Iijima, Director) of the National Institute for Advanced Industrial Science and Technology (AIST; Hiroyuki Yoshikawa, President) has developed a novel synthesis method for SWNTs (single-walled carbon nanotubes) to be the core material for nanotechnologies. This method modified from the DIPS (direct injection pyrolytic synthesis) method has dramatically improved an accurate control of the reaction conditions to achieve high purity and a high degree of graphitization. The purity of the nanotubes increased from 50% to 97.5%, and the structural defects in the nanotubes was reduced to one tenth of the previous level. As there is no need for purification processes, surface treatments or use of binder, these high quality SWNTs can be used directly as high strength threads (SWNT wire) or as SWNT mesh sheets for cell culture.

The results of the present research were presented at the "Advanced Nanocarbon Application Project Symposium" organized by the New Energy and Industrial Technology Development Organization (NEDO) on May 12, 2006 under the title "Research on Catalysis and Processes of Single-Walled Carbon Nanotubes"

SWNTs manufactured through conventional mass production technologies produce a large amount of impurities that require aftertreatments for purifying or modifying and become an obstacle to their use as an industrial material. Delivering SWNT in this form could be compared to delivering coal and asking the user to refine or modify it before using it, with the corresponding investment in time and effort. The refining process could be also detrimental to the quality and homogeneity of the SWNTs, creating problems from the point of view of quality control and hindering their use as an industrial material.

Under the direction of Sumio Iijima, the Research Center for Advanced Carbon Materials has been tackling two important topics: synthesis and application of SWNTs. Recently, Dr. Takeshi Saito et al. has concentrated efforts on developing a mass production technology for SWNTs using the DIPS method, identifying the main points that allow an accurate control of the reaction field during the synthesis of SWNTs, and enhancing the conventional production method to improve the quality and catalytic efficiency of manufactured SWNT.

The present research has been supported by the NEDO under the "Advanced Nanocarbon Application Project" of the Nanotechnology Program (FY 2002 - FY 2005).

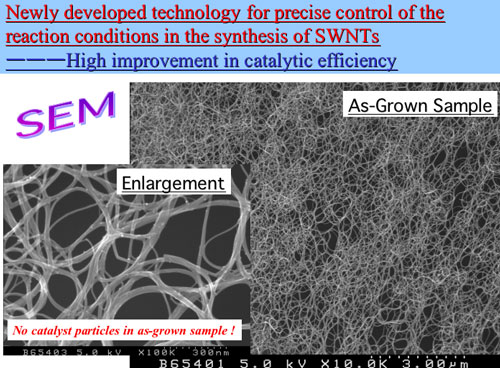

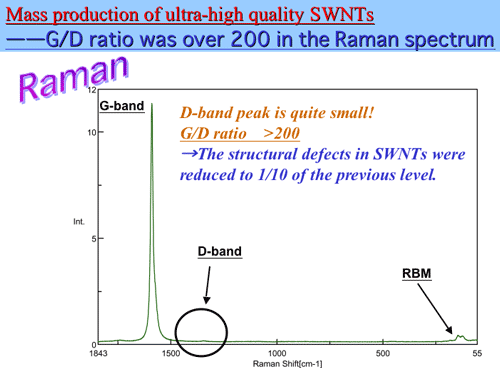

At the AIST, research on mass production technologies for manufacture of SWNTs has focused on achieving accurate control of the raw material decomposition temperature and the reaction field. The enhanced DIPS method constitutes a mass production technology for high quality SWNTs with purity higher than 97.5%, and a structural defect rate less than one tenth of the previous value (Figure 2). Not only is this value considerably higher than the current value for purity in SWNT (50%), but the catalytic efficiency has also been increased to 3900%, which represents one hundred times the current productivity.

|

|

|

Figure 2. Characteristic data of high quality SWNTs

|

This epoch-making synthesis technology has established the importance of controlling the reaction field during the DIPS reaction of SWNTs, As described above, not only it has improved the quality of mass produced SWNTs (purity and graphitization degree), but it has also allowed the control of the mean diameter of SWNTs on the order of 0.1 nanometer. As standardization of nanomaterials is being enthusiastically pursued, it is expected that this technology will be used for production of SWNTs, considered to be a core nanomaterial, as a reference material.

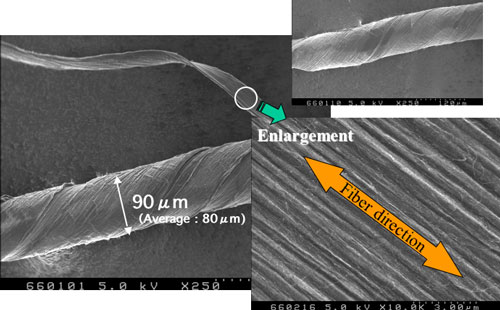

These ultra-high quality SWNTs form a homogeneous nano-sized and extremely light spongy structure. This characteristic can be exploited to produce SWNT structural materials to be used in the "as received" condition without any surface treatment or binder addition. The SWNT has an excellent workability that can be used directly produce versatile products such as high strength spinning SWNT wire (Figure 3) and SWNT sheets for mesh for cell culture.

|

|

Figure 3. High strength SWNT wire produced without surface treatment and binder

|

As described above, this epoch-making technology not only allows mass production of high quality SWNTs, but also represents a completely novel approach to the processing of this material. This technology is expected to become a breakthrough that will accelerate applied research on bulk materials such as nanotechnology-based composites. From the point of view of quality and productivity of synthesized SWNTs, the present technology can be considered to be the most advanced technology in the world, and its technical preponderance is evident.

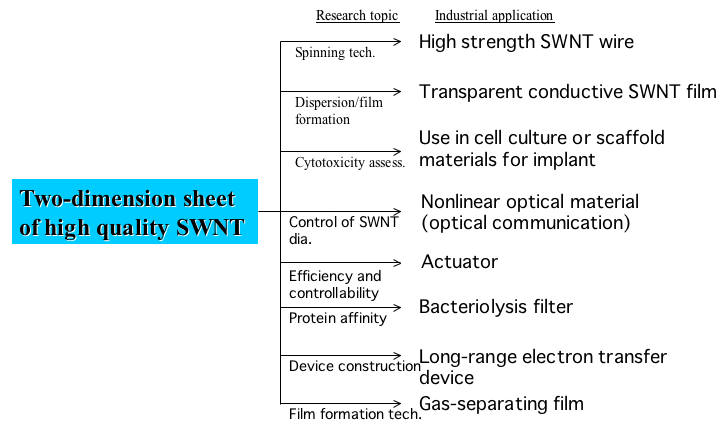

The present synthesis technology can be applied to the development of novel materials with epoch making characteristics to be used in diverse fields such as medical care, biology, chemistry, composite materials, and nanotechnology (Figure 4).

|

|

Figure 4. Applications and research topics for high quality SWNTs

|